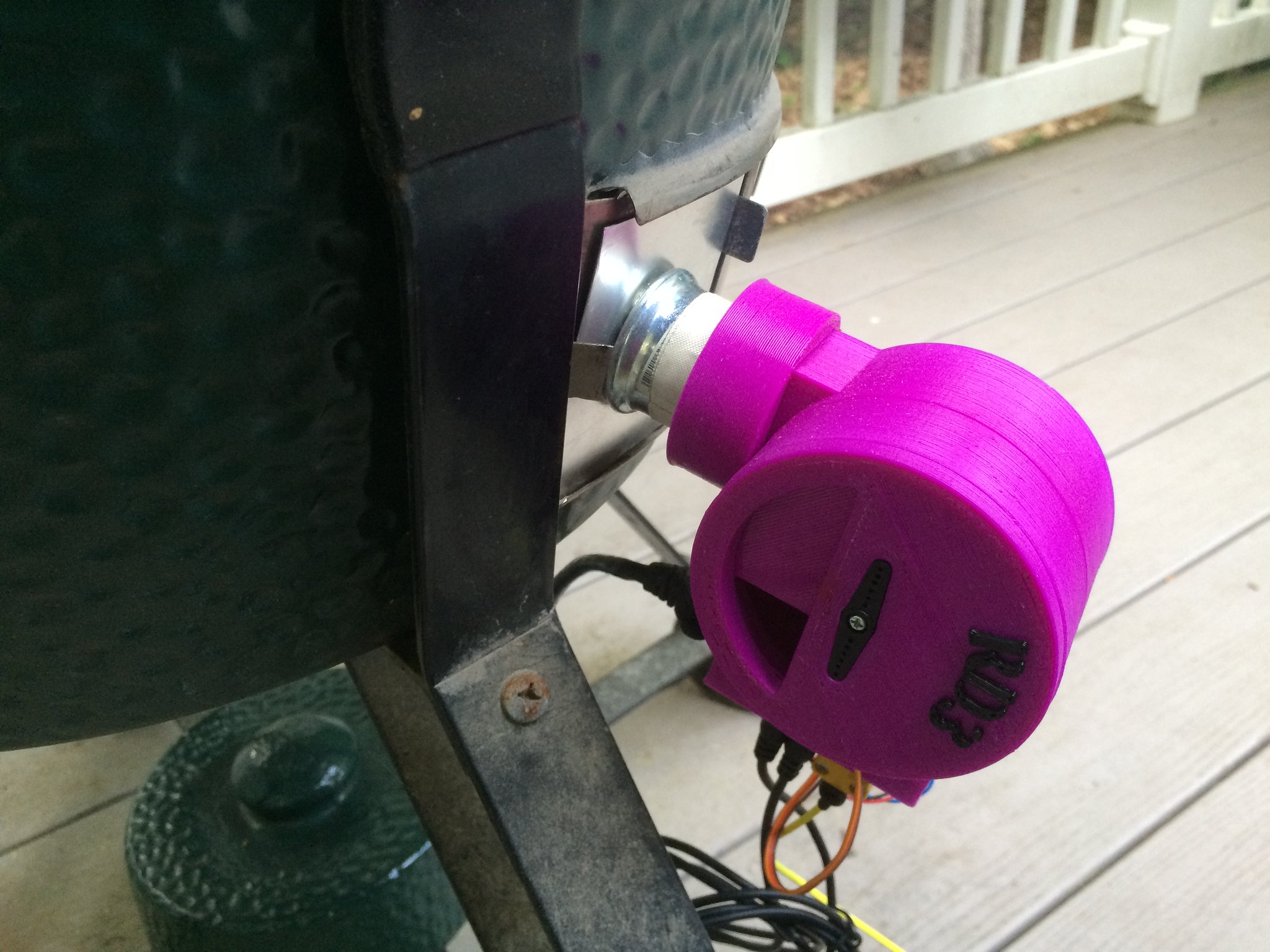

I've had some people asking how the low and slow performance is with the new RD3 so I did a real world test cook tonight.

I started the "fauxmado" with half a weber starter cube under a pile of Royal Oak lump coal pushed to the back half of the burn plate. (the coals had been burned previously, ash shaken off and lit back up)

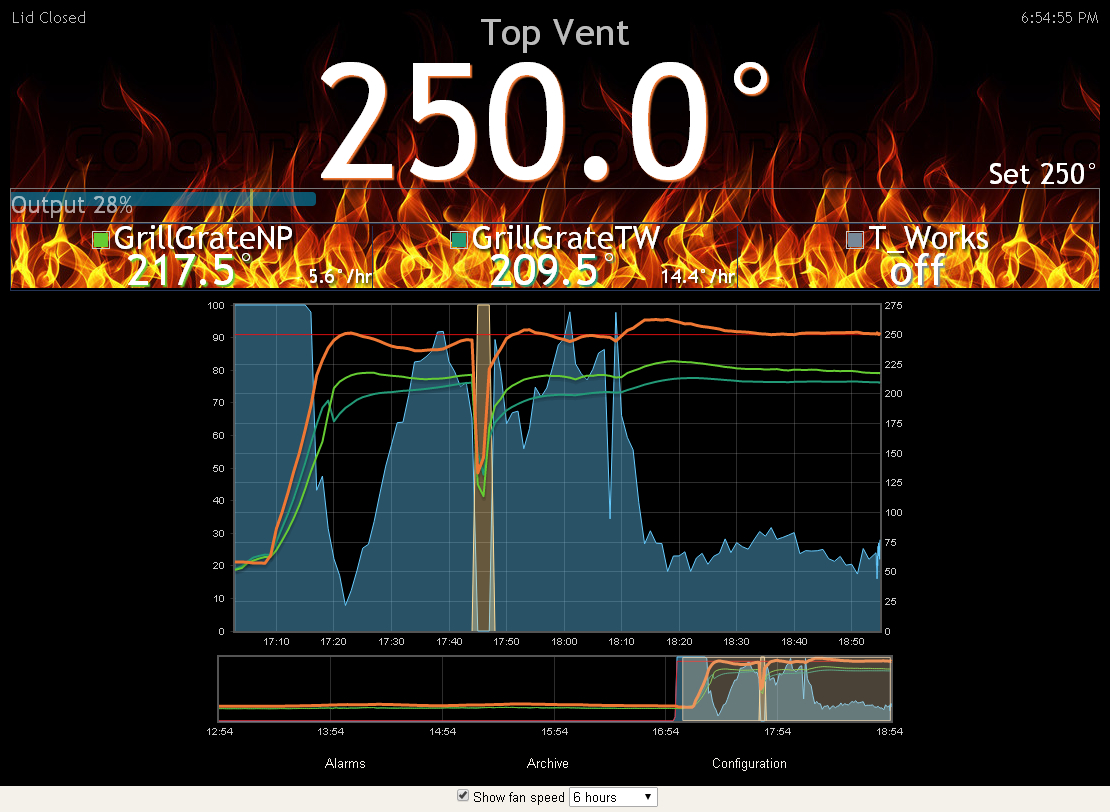

The HM is running the (old) stock PID settings, fan Startup Max 100%, Min 0% and Max 10%, Fan on at MAX ONLY.

I waited until the smoke from the starter cube went away and then closed the lid, leaving the top vent open only a crack.

The pit rose rapidly to the target of 250F, as it approached the setpoint the HM reacted by backing down the output. When the output moves from 100% to 99% (or below) the fan goes off completely and the damper takes control.

The RD3 hit the setpoint almost exactly, followed by a slight dip in temp as PID adjusted to the lack of blower output.

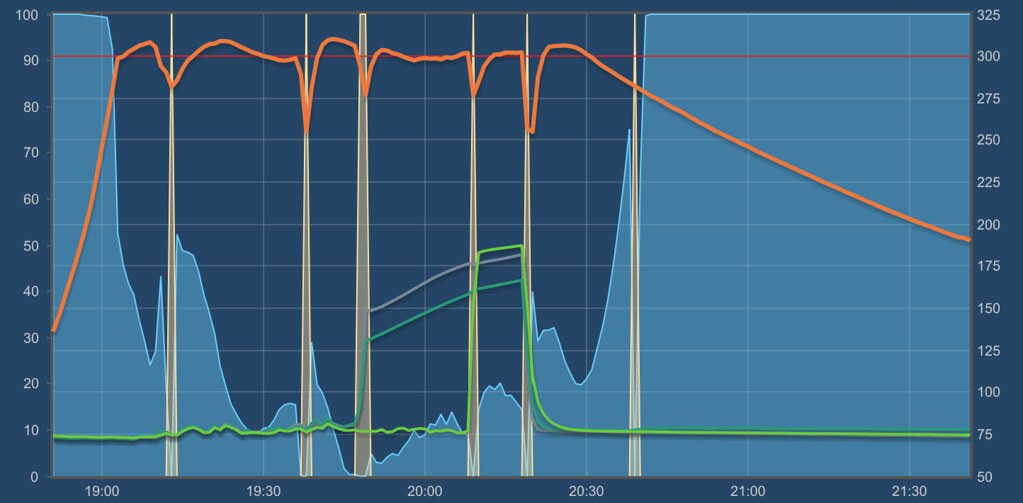

As the pit approached the setpoint again I opened it up and threw on a rack of baby back ribs, a couple cups of mopping sauce in a bowl and threw a couple chunks of cherry wood on the fire and closed the lid.

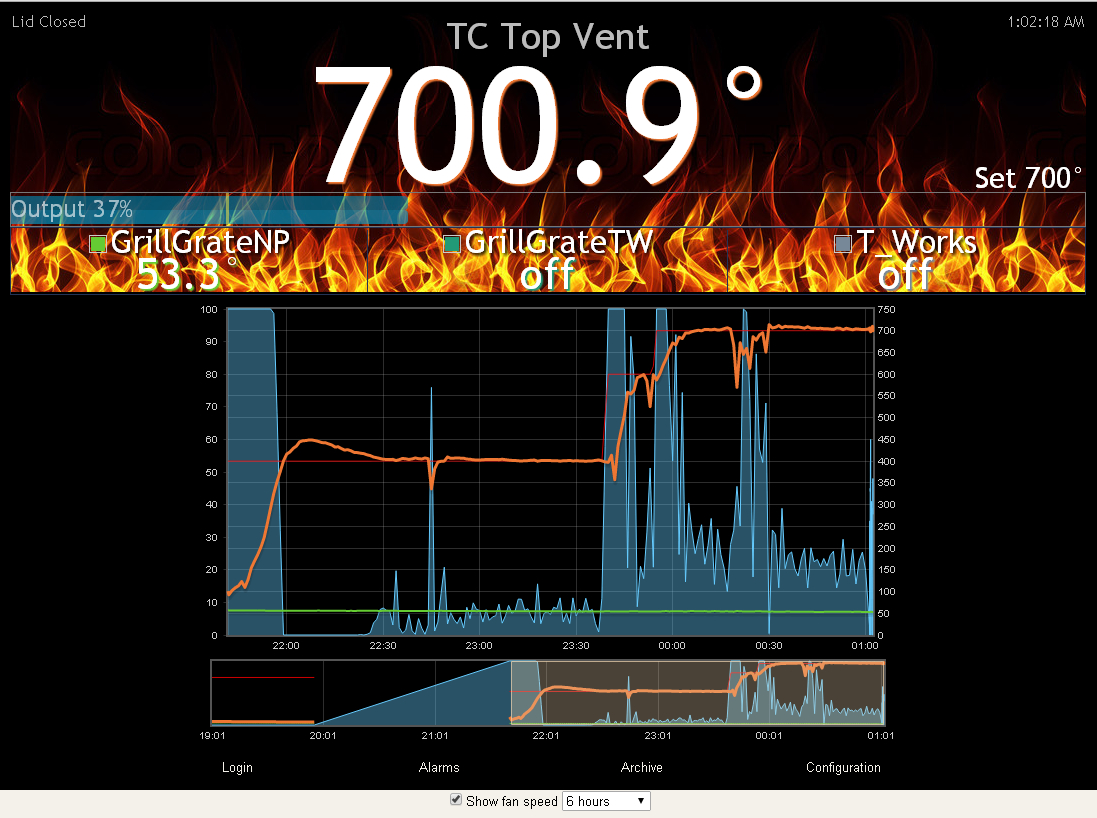

The RD3 hit the setpoint pretty tight again, slight overshoot and was heading for undershoot... From the blower graph I can see the damper is running way high, in the 80% range, indicating the air flow is a bit restricted by the top vent being set to a small crack... so at 18:10 I open up the top vent a nice bit more. The pit has an initial overshoot reaction to this adjustment and then settles nicely on the setpoint with the damper open about 25-30%.... PERFECT! All tuned up and ready for the long haul...

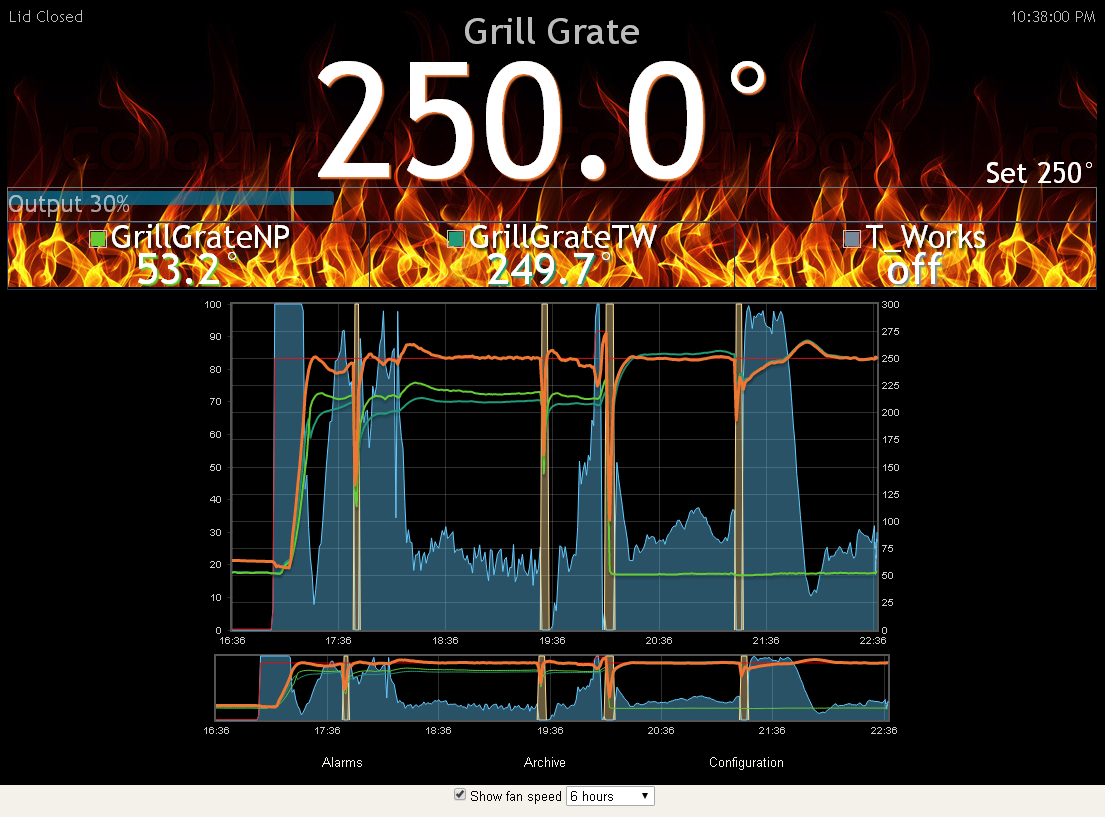

As most of us know already, one of the hardest ways to do low and slow is with frequent lid openings for basting. These ribs I did with a mop sauce and opened the grill every hour or so to mop. The HM and RD3 did an excellent job keeping temps in check after opening the lid to mop. Since I am using the offset method, with the fire in back and ribs in the front, the mop sauce was not running of onto the fire and slowing it down.

I did mention this was a "real world" cook, right? So right at about 20:00 mother nature threw her hand in the process and hit us with some cold wind and rain. I was running the pit with my Thermoworks thermocouple, which is a long thin needle, stuck down into the top vent. Part of the needle was hanging out of the pit and the cold rain hitting it started to effect the pit reading (note the dip in temp around 20:00)

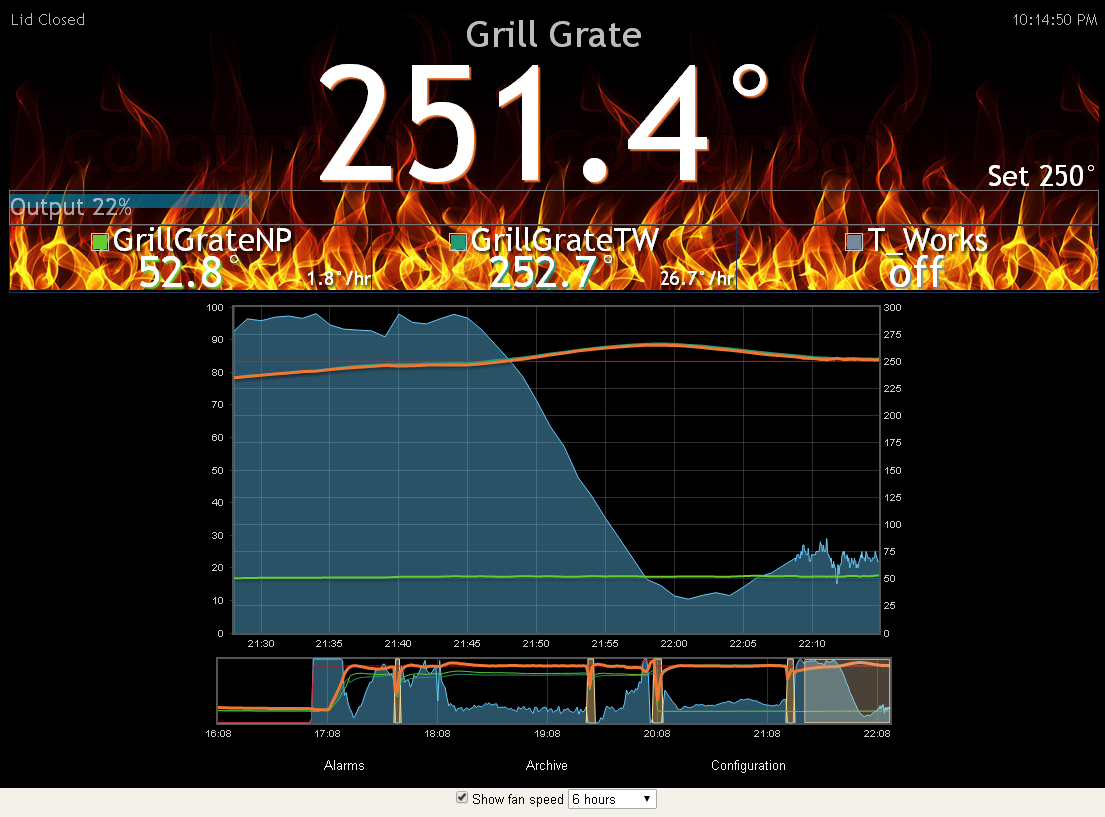

At first I compensated by boosting the pit temp to 275F, because my grill grate temp was lagging a bit and running around 215F and I thought it was time to speed things up a little bit anyway. Then I decided it was probably best if I just move the pit probe down to the grill grate, so it is fully inside the grill, and let the HM pull the grill grate area up to a setpoint of 250F. You can see where I make that change on the graph, during the lid opening where the "GrillGrateNP" probe gets tossed out of the grill to the chilly ambient temp in the lower 50's.

From that point on the TC pit probe and the grill grate probe track almost exactly on top of each other. At this point I think it is worth mentioning that the RD3 and these probes are all being run over a 50Ft+ long CAT5 cable using the RDTC board in the RD3, in the rain.... The temps are super stable and the whole rig is working great!

After the final basting I notice the damper is running a bit high again, up in the 90% range, so I crack the top vent open some more. At this point the top vent is about 40% open, which is pretty wide for a low and slow on the "Fauxmado". The pit reacts to this with initial overshoot (same as the with the first vent adjustment) and then settles down right on the setpoint again... "Good pit".... I love it when they behave! LOL

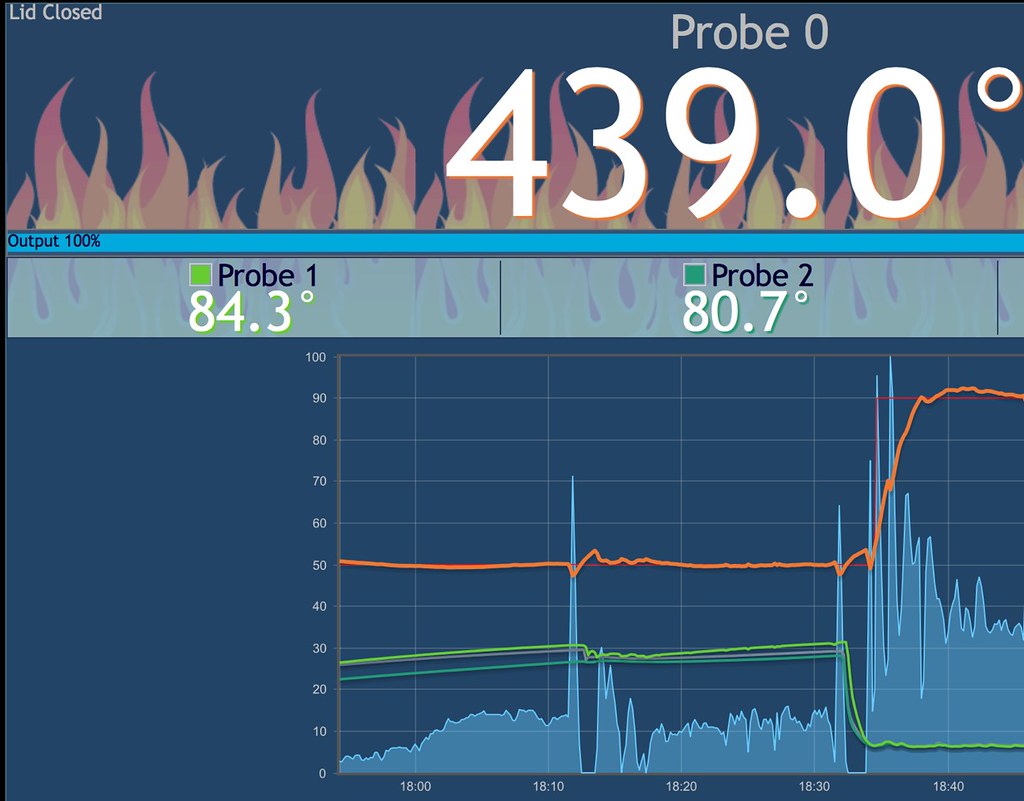

You can see on the graph, even through the brief periods of overshoot the HM is not completely closing down the damper. I much prefer this compared to setups where the temp overshoots and the damper completely shuts down. A complete shut down is choking the fire and possibly causing the less desirable more bitter type of smoke to be produced, and at the same time is restricting flow in the pit to hold that smoke inside the pit and around your food. With the damper only setup (fan on at Max Only) the HM adjustments are more subtle, the HM isn't being thrown off by peaks in temps while the air flow is choked, and then thrown off again by the rush of cold air when the blower kicks on.

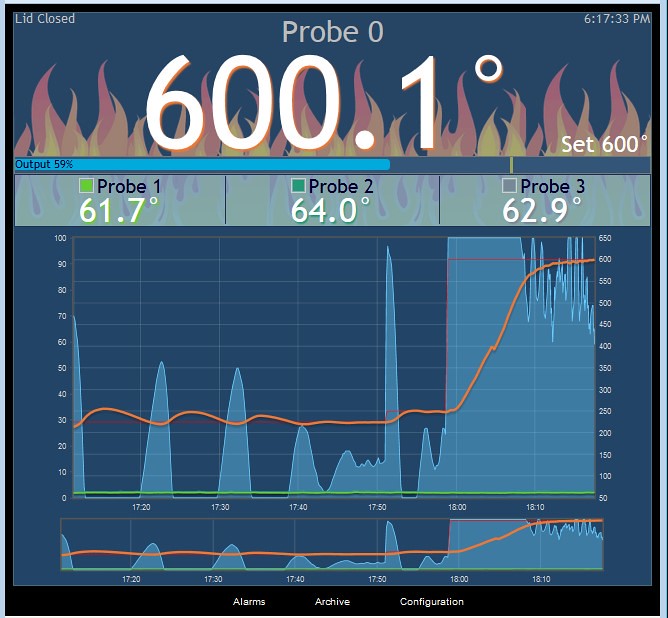

Below is a close up showing the graph during the largest period of overshoot, after the second vent adjustment. Notice how even though the pit temp is above the setpoint the HM isn't completely choking off the fire...

I am completely thrilled with the low and slow results using the RD3, as you can see from the graphs it had complete control over the pit even through lid openings and dicey weather. The night before I did searing at 600F and that went great as well. For the high heat cook I remove the "on at Max Only" setting and set both the Max and Startup Max to 100% for the fan and allow it to stoke the he!! out of the fire, running the top vent fairly wide at 50-75% open. I didn't get any screen captures of that because high heat cooks go so fast and the next thing you know it's time to eat! Next time I will try to remember to make a screen capture during a high heat searing or pizza cook....