From my experience of using a blower on my UDS for 4 years or so...

Do you need a damper/blower? Nope, the UDS will hold temperature perfectly flat +-1 degree for many hours with just using the ball valve.

Can you use just a blower? Yep, I did this way, 3 years or so.

Further, would it be even better if I ran the servo (damper) in the "fully open or fully closed" mode, and let the blower speed maintain the proper air flow?

Yep, this is the way I run mine on the UDS, and it will hold awesome temperature.

If so, does that mean my UDS needs a bigger damper, or just use a blower with no damper?

If not using a damper or blower, having more or a bigger air inlets would be just as good as have a 1 inch(same as mine) and a blower(with or without a Rotodamper). If properly setup using the ball valve and a blower, you don't need to use a Rotodamper on a UDS, in fact I just use mine as a way to mount the blower to the smoker.

Intuitively, I prefer the concept of controlling convective air flow instead of forced air (blower).

Then you would most defiantly, would need more air inlets around the bottom of the UDS, the Rotodamper wont by its self control the UDS, as the half moon shaped air inlet restricts some air and a 1 inch inlet would not be enough. I originally has 4 3/4inch holes for inlets and would control the UDS with the ball valve, but I usually had one of the other holes cracked open or fully open to get the temperature to stay at setpoint. The problem with that, if using a RD in the mix would be getting everything set correctly and that can be a big hassle, trying to figure out exactly how much to open other air inlets to help the RD maintain a steady temperature, if the wind picks up be prepared to manually change the air inlets not being controlled be the RD.

Perhaps I need an inlet bigger than 1 inch? Also, do larger exhaust ports 'encourage' better convective flow - due to better draft? My current exhaust is 4 1" elbows on the lid.

Yes, bigger inlets would help. I use a Weber top on my UDS and it only has the 4 outlet holes on the lid, so the 4-1 inch outlet hole should be ok.

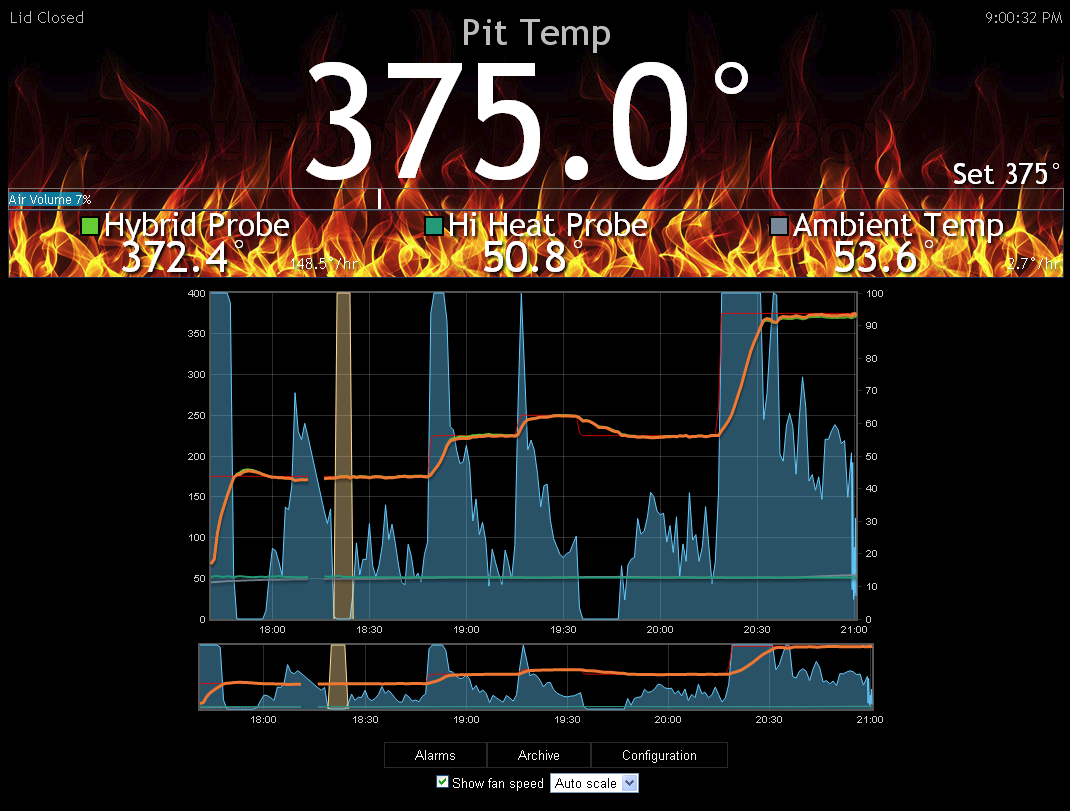

Next, weekend, I am going to be testing a new HM for somebody I just built for them. I will be using a 25CFM blower and a RD. I will post the link on the thread for your live cooks, and if you get a chance to take a look, you will see the benefits of using a bigger blower. The UDS needs a minimum of at least a 8.4 cfm regardless of using anything between .5 or 1 inch pipes on the air inlet I have used both without much difference. Although, If you plan on higher heat during colder months, then having extra inlets would help. Temps above 40 the 1 inch, should be fine for UDS cooks.

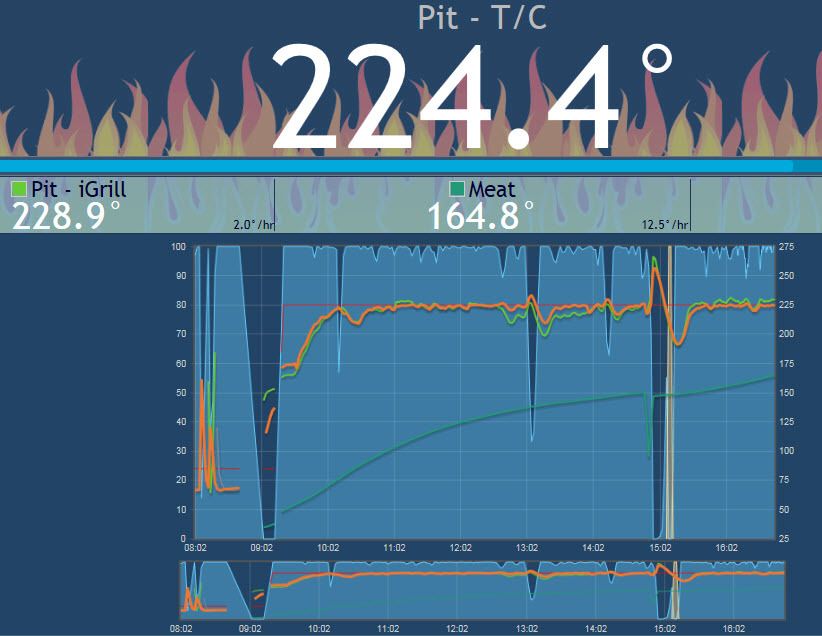

Most people would agree that the UDS runs perfect without any blowers and Servo dampers, Its a set it and forget it smoker, and I agree with that. Mine would stay at 230 for hours and hours sometimes. But, using a blower, you need to restrict air flow, so that the blower controls the smoker and that's the whole idea of using a servo controller, to restrict the air flow, so that the blower can do the work quickly and then the servo closes the air inlet. If you look at your graph above, The blower is continuously running at 100% for the most part, is not really controlling the smoker. Its not able to push in enough air into the smoker. 6.5 cfm on the UDS is just way to small. I can start my UDS charcoal basket and then set the setpoint on the HM and walk away, knowing that the Temp will be at setpoint within a few minutes, unless its running hot then it could take a bit of time to settle down first.

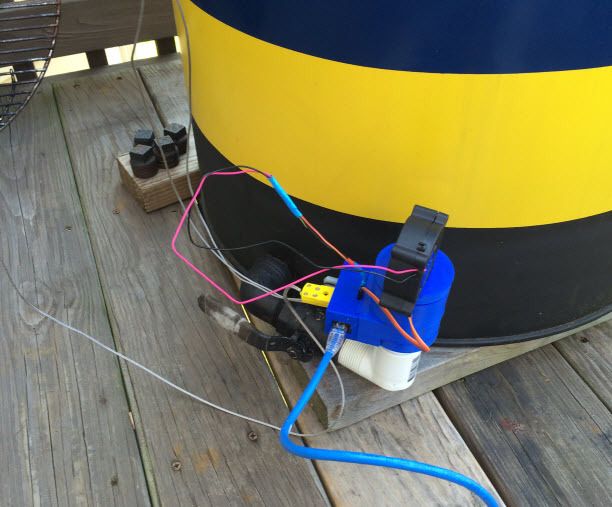

Here is a pic of my setup