RalphTrimble

TVWBB Diamond Member

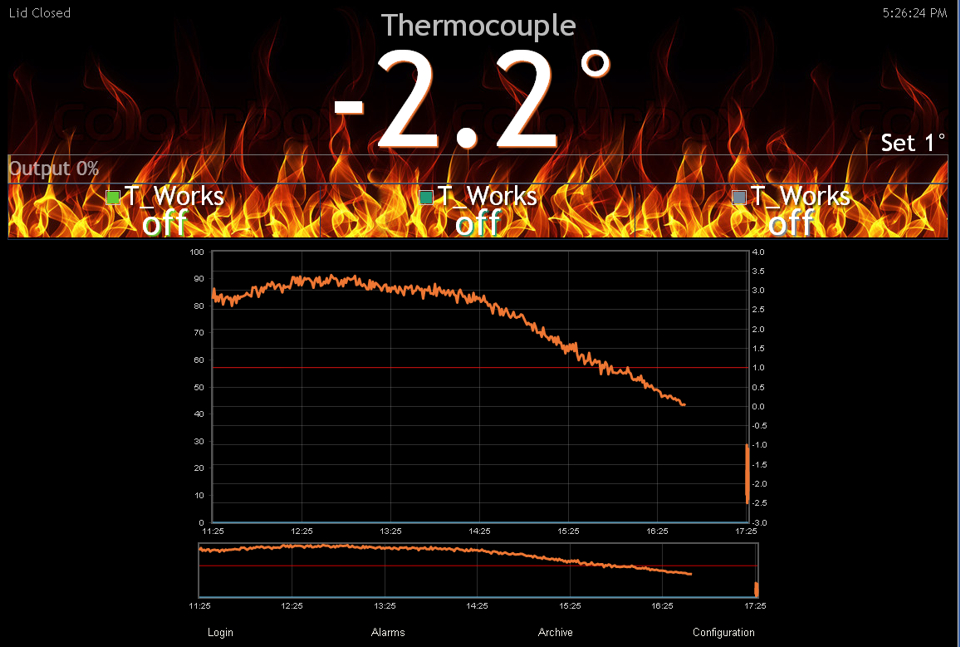

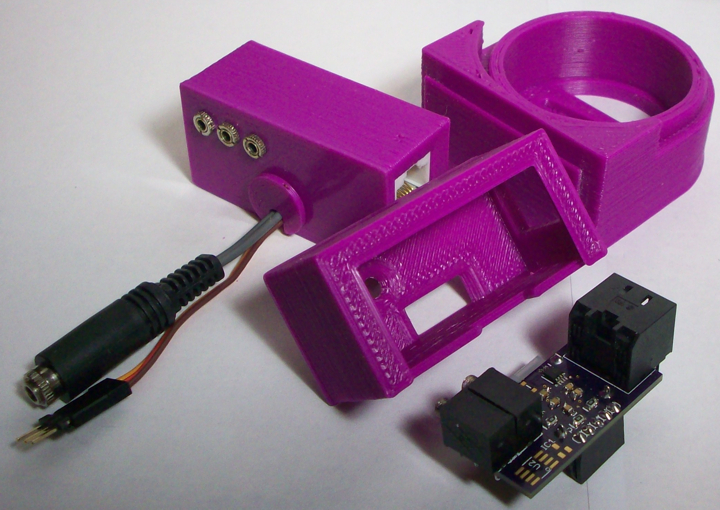

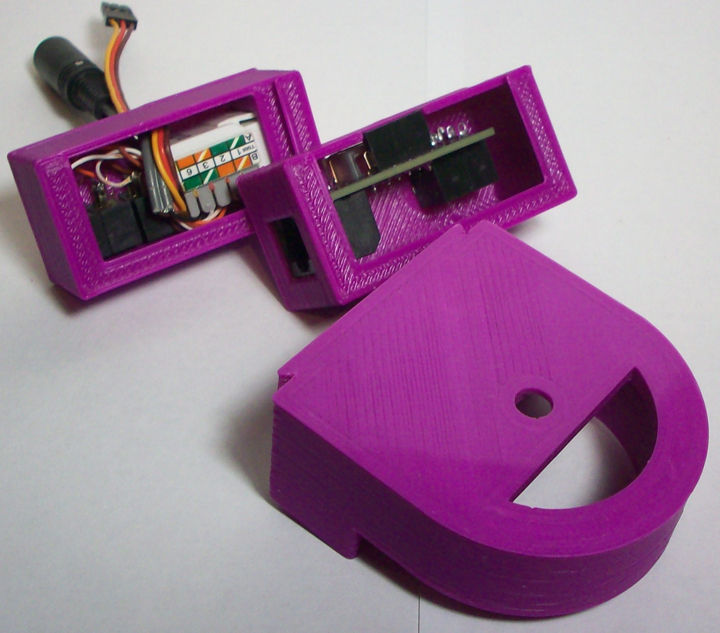

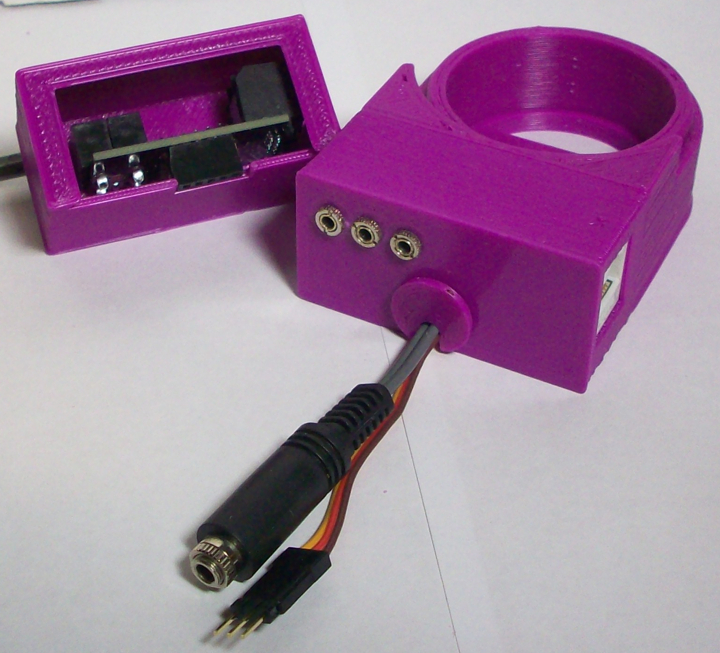

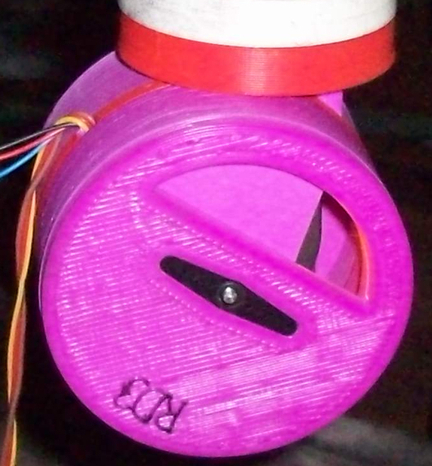

So the weatherman says our lucky streak is about to end in the midwest and sure enough the HM dips down to about 0F, so I say to myself... Why not cook a hand made pizza, on the grill... I throw together some dough then light the trusty "Fauxmado" and attempt to connect the latest damper to my CAT5 cable for a high heat test run... Nothing... I guess when its 30F below freezing you expect these things... So I crimp a new end on the CAT5 cable... BINGO... Off to the races...

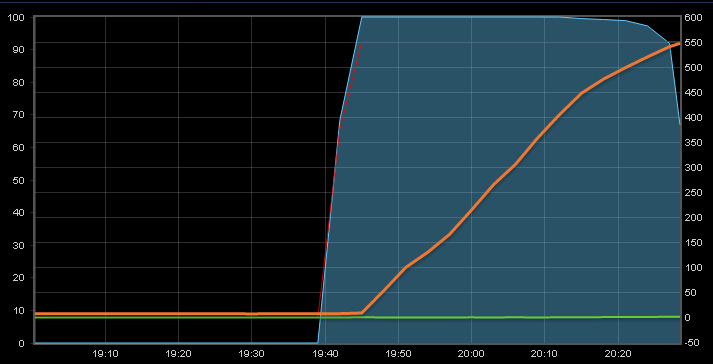

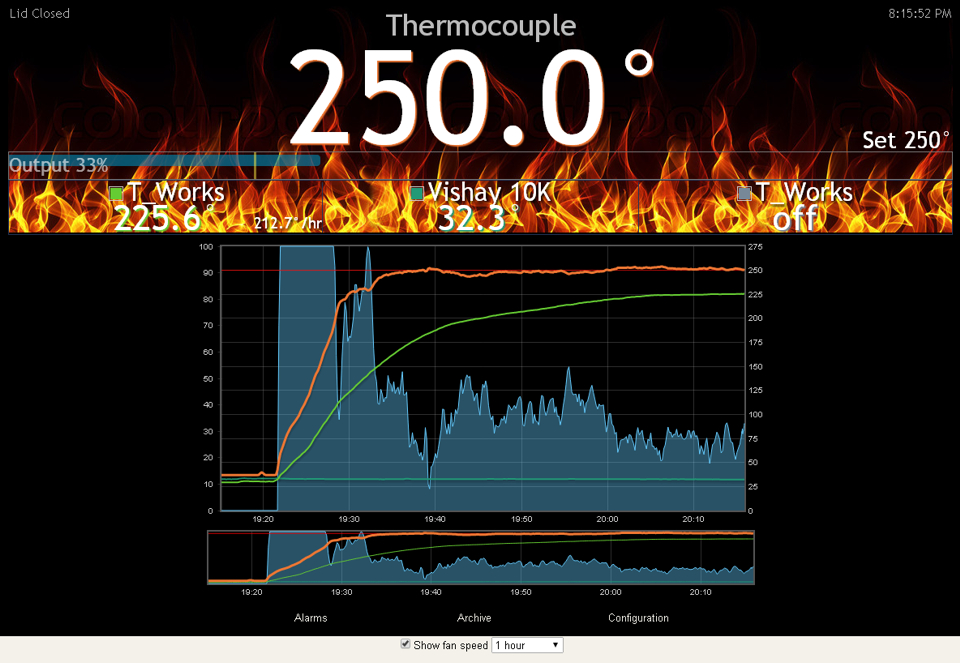

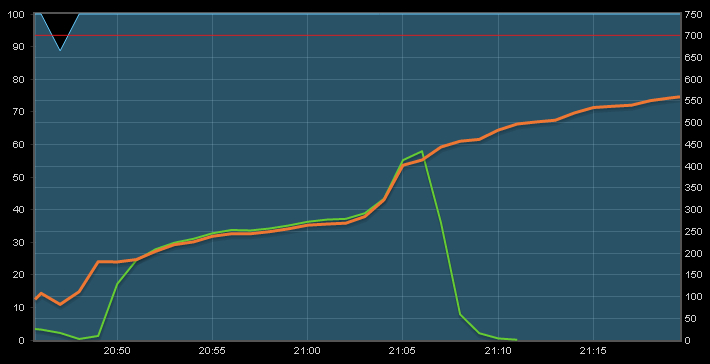

Above is the graph of initial warm up until I had to pull the standard probe out of the pit before it melted... Yah, it goes down to 0F, that is the outdoor temperature right about now...

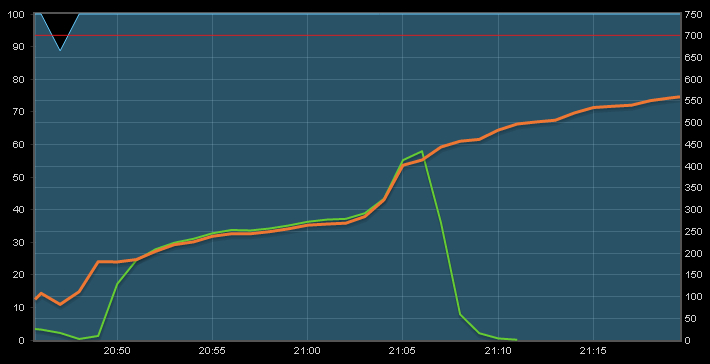

So on goes the pizza...

...and 18 minutes later...

Some serious heat shock happening to that pie when I open the lid to 0 degrees fahrenheit!

You know I ate the whole thing!

Above is the graph of initial warm up until I had to pull the standard probe out of the pit before it melted... Yah, it goes down to 0F, that is the outdoor temperature right about now...

So on goes the pizza...

...and 18 minutes later...

Some serious heat shock happening to that pie when I open the lid to 0 degrees fahrenheit!

You know I ate the whole thing!