Ever since I built my 3D printer I wanted to take a stab at designing a Heater Meter case, but Tom and Matt make such nice case designs I've just been using theirs. At this point my 3D modeling skills have come along a bit, and since I have here a prototype Heater Meter board I thought this would be a good time to dig in and give it a try. Of coarse I wanted to do something different, so I shot for an ultra small press fit case, this is what I come up with so far....

Here's a pic of the unit next to a Bic lighter as a common reference of scale:

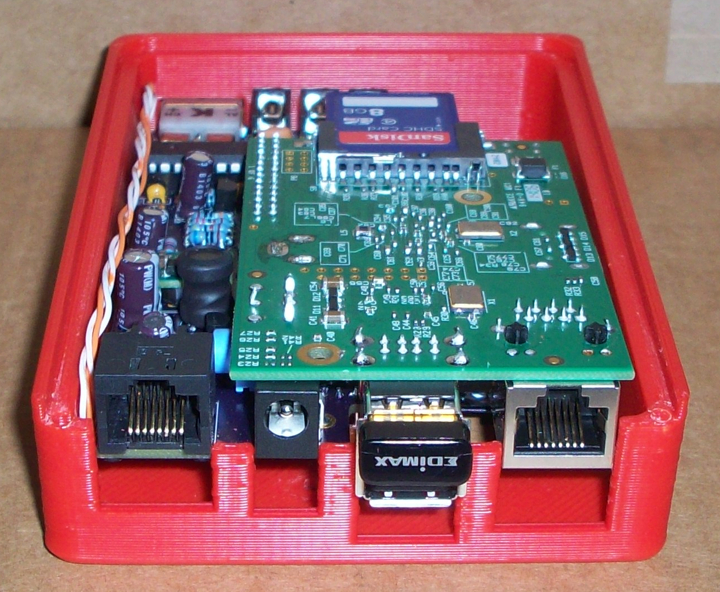

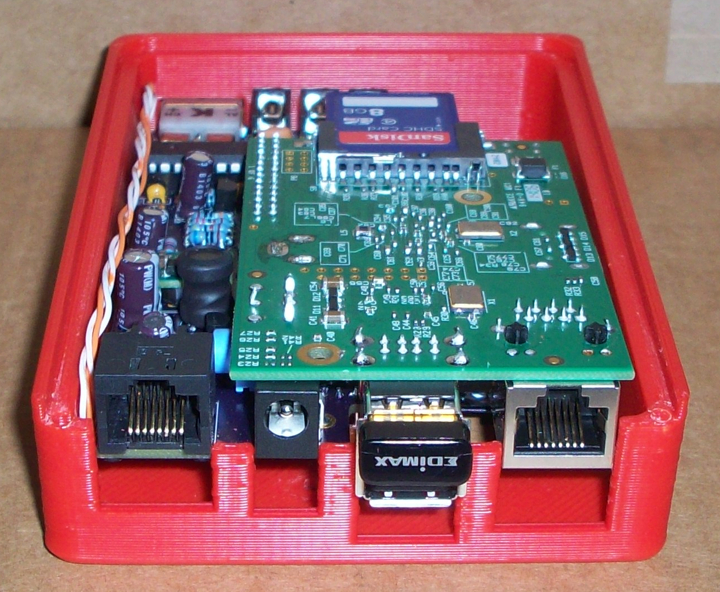

Instead of cutting the case in half I made the case body one big shell, you insert the probe jacks into the holes on the case and then rotate the board set down into the other side of the case. It works out really well on this board set I have here.

Here is a pic of the empty case:

...and a pic of the board set going into the case:

I've had great success withe press-n-fit objects with the roto-damper so I thought I would give that a try. Unfortunately that works much better on round objects than square. The first back I tried was just flat, it did press-fit and hold in place but not to my liking. I've tried a couple other ideas.... this one has pegs in the back that push into the case, though that is a kinda fragile deal so I am shying away from that. What I have here works for me and is pretty solid, I don't worry about it falling apart, but I will brainstorm on it for a while and see if I can come up with a better press-n-fit design before Bryan makes the official release of the HMv4.2.X board. If all brainstorming fails I will put two screws through the back on the side with the rPi I/O where the pegs are now. I'm thinking the mounting screws they supply with the servo would be a nice easy option, since I don't need them with the roto damper, or anything similar. It doesn't need to hold much since the case and back mate nicely and the press-fit already holds things in place.

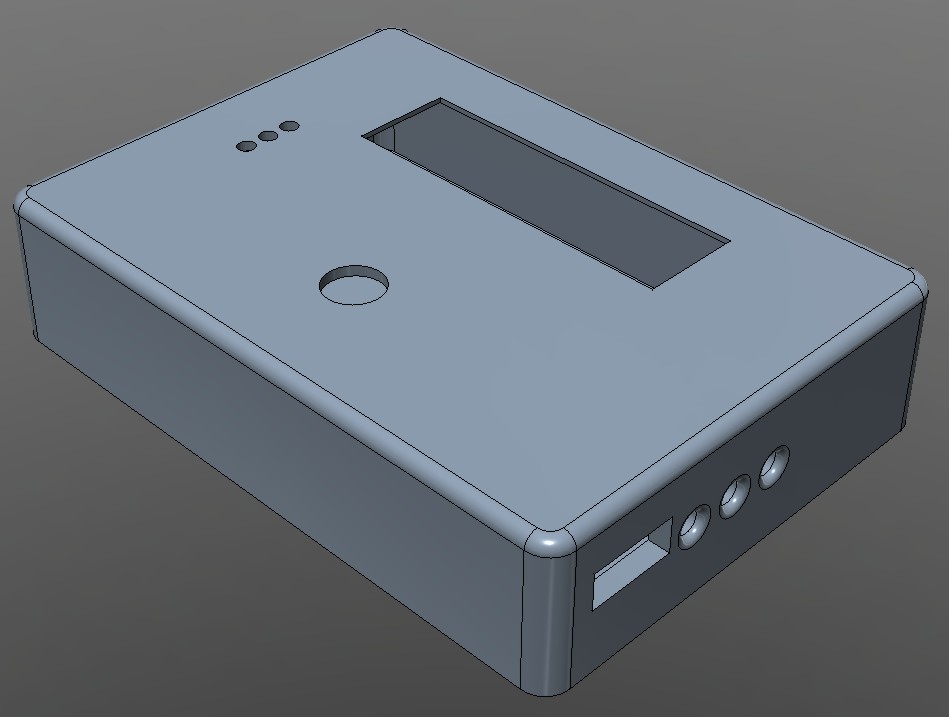

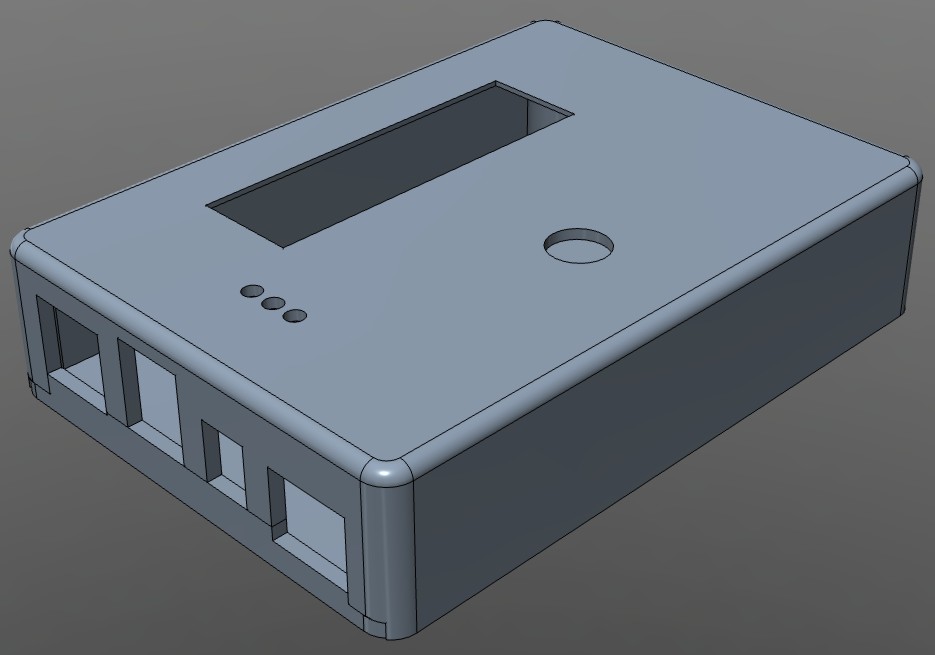

Since the LCD is up there so high on this unit the stock button for the switch stuck up pretty high and looked kinda obtuse, so I designed my own button nub, I'm really happy how that worked out. It sticks out just enough to activate with your finger and I think it looks really good...

Here are a couple of pics of the object from the 3D modeling app 123Dbeta...

All in all I am pretty happy with how it came out, but like

roto damper and Heater Meter itself, this is a work in progress and I think it will evolve over time...

Here is a

link to the STL's in case anyone wants to check it out, remember, it's a work in progress....