Aaron Morris

TVWBB Member

Where are those one stored at? I didn't see them on the google drive front page links.

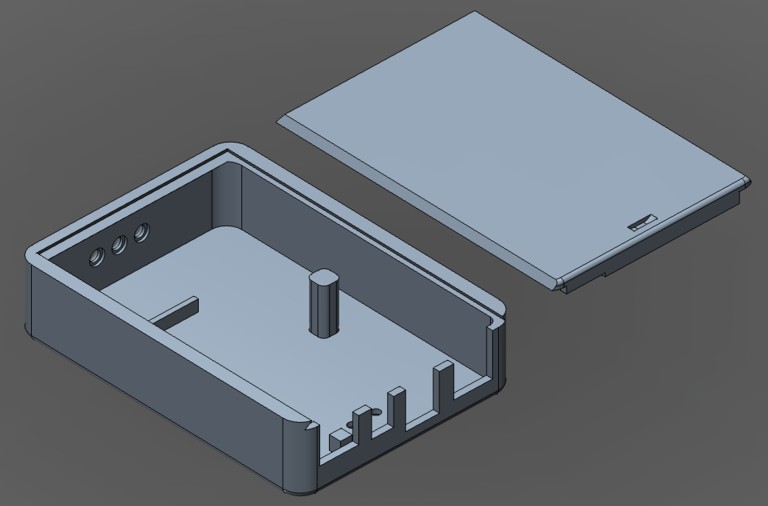

Hi Tom, it sounds like your doing it would take about a 10th the time it would take me to even install the program, so if you don't mind doing it that would be great! One concern is that without the LCD attached, will the internal supports on the case still be sufficient? I am having trouble visualizing it. Thanks.

Anyone know of any UK printers? I PM'd Tom but haven't heard back so assume he's not printing anymore

What size screws and nuts are these sized for? 256 ?