Paul Nederveen

TVWBB Member

Hi folks,

I tried my first HM controlled cook this weekend. It worked and it didn't work. My setup is as follows:

Primo Oval XL cooker.

HM 4.2.4

2x iGrill Thermistor probes (from a still working iGrill bluetooth temp monitor)

1x Perfect-Prime TL0500 K-Type Sensor alligator clip seen here.

Micro Damper by Steve into a homemade damper plate.

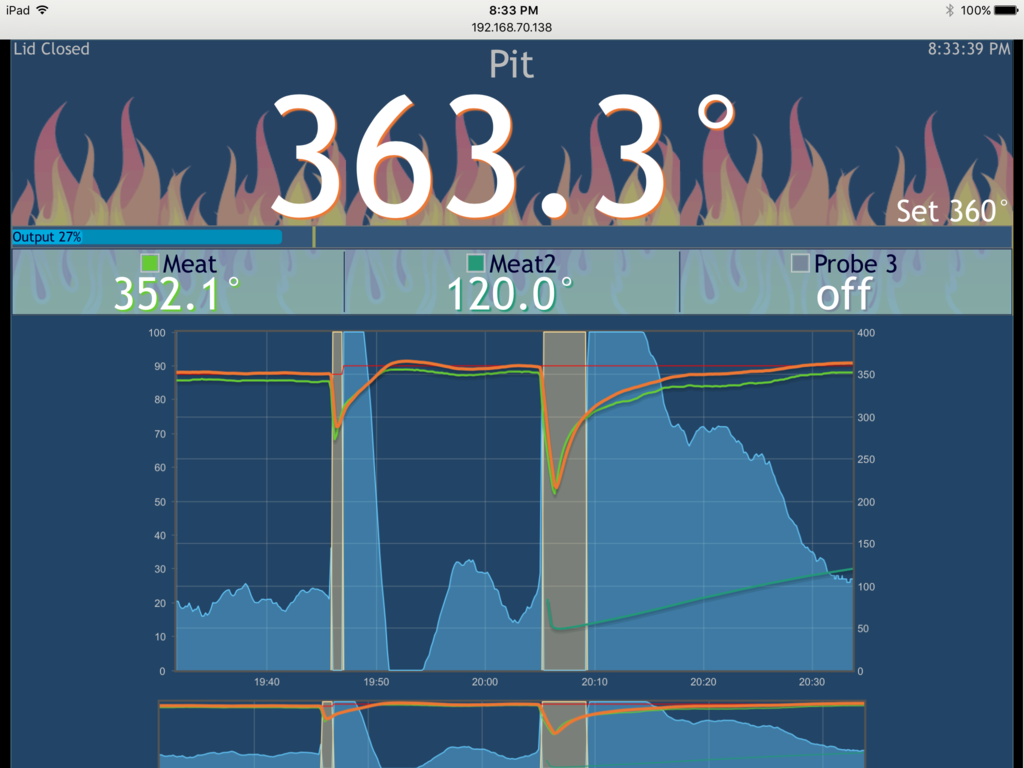

I got the smoker going with the HM attached, set point at 215 (set for 225 later). Everything seemed stable, and I put the shoulder on to start smoking. So far so good. The HM held the temp perfectly around the set point and I ramped it after the first 6 hours.

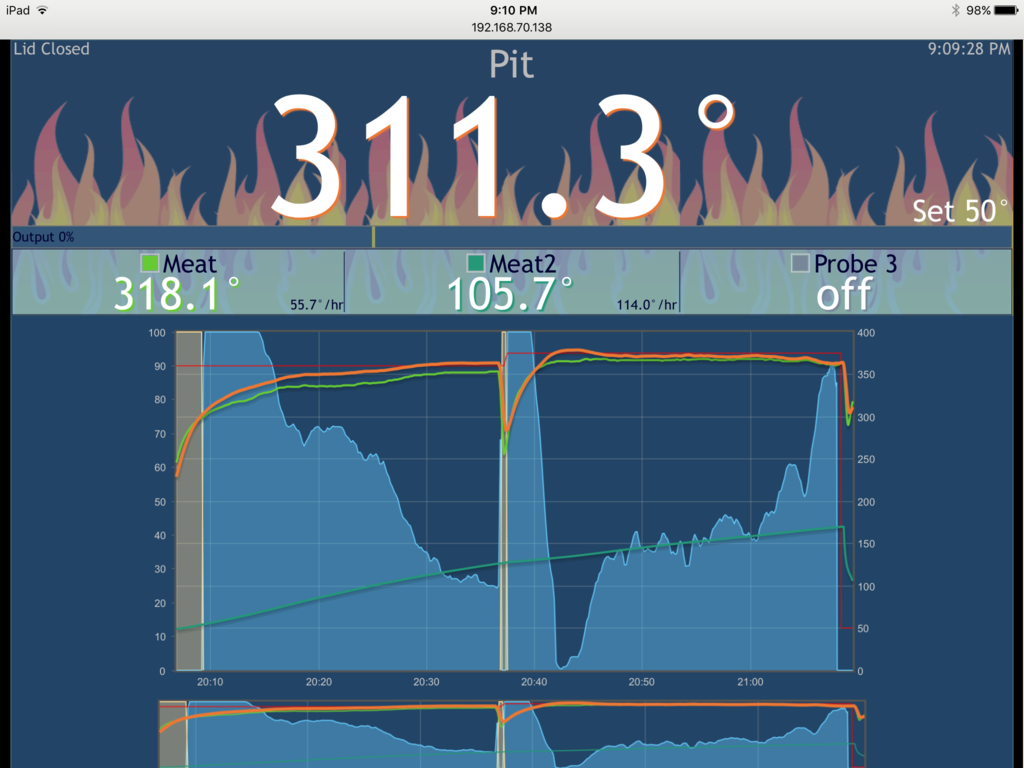

After 12.5 hours the meat hit 170.4 and started falling. I figured it was a stall. Meat temp started dropping and kept dropping for the next 2 hours! I raised the set point a bit and then I got worried and started doing some investigation. My built in grill thermometer was reading only 200 degrees. I expect it to be a bit lower but 25 was a big gap.

I put the spare iGrill thermistor probe in next to the TC probe as shown in pic:

The grill thermometer and the thermistor registered the same 200F. The difference ranged from ~25 degree (TC=225, TM=200) up to over 60 degree difference (TC=~315, TM=~250). For sanity I plugged the same thermistor probe into the iGrill and the HM and they were exactly the same temp.

I had already calibrated my TC in freezing and boiling water. Stock settings for voltage and 0 offset. I checked it again today in boiling water and was reading 212-213 and .502V on the output of TC circuit. (as per this thread)

I need help on understanding why the TC seemed to have an increasing error and what I should be doing different.

Thank you all!

P.S. The pork was safe to eat and tasty but not as tender as I would have liked...beer helped me calm down eventually.

I tried my first HM controlled cook this weekend. It worked and it didn't work. My setup is as follows:

Primo Oval XL cooker.

HM 4.2.4

2x iGrill Thermistor probes (from a still working iGrill bluetooth temp monitor)

1x Perfect-Prime TL0500 K-Type Sensor alligator clip seen here.

Micro Damper by Steve into a homemade damper plate.

I got the smoker going with the HM attached, set point at 215 (set for 225 later). Everything seemed stable, and I put the shoulder on to start smoking. So far so good. The HM held the temp perfectly around the set point and I ramped it after the first 6 hours.

After 12.5 hours the meat hit 170.4 and started falling. I figured it was a stall. Meat temp started dropping and kept dropping for the next 2 hours! I raised the set point a bit and then I got worried and started doing some investigation. My built in grill thermometer was reading only 200 degrees. I expect it to be a bit lower but 25 was a big gap.

I put the spare iGrill thermistor probe in next to the TC probe as shown in pic:

The grill thermometer and the thermistor registered the same 200F. The difference ranged from ~25 degree (TC=225, TM=200) up to over 60 degree difference (TC=~315, TM=~250). For sanity I plugged the same thermistor probe into the iGrill and the HM and they were exactly the same temp.

I had already calibrated my TC in freezing and boiling water. Stock settings for voltage and 0 offset. I checked it again today in boiling water and was reading 212-213 and .502V on the output of TC circuit. (as per this thread)

I need help on understanding why the TC seemed to have an increasing error and what I should be doing different.

Thank you all!

P.S. The pork was safe to eat and tasty but not as tender as I would have liked...beer helped me calm down eventually.

Last edited: