I just heard back from Thermoworks about the thermocouple I was thinking of using, which I posted about the other day.

Model: 113-420/425

They said it is an isolated thermocouple, so I think it might work out OK...

I stuck this in the spot the normal dial thermometer goes last night and set the HeaterMeter for 225F, 375F, 500F, 600F, and 700F. HeaterMeter had no problem holding any of these temperatures and there was no noise to speak of. 1 LSB above 400F is 1.16F (before oversampling) so you don't see smooth 0.1F degree changes, but I think there are enough variations in heat that you might not get those anyway. I had to open the top to get to 600F, and slide open the bottom damper about an inch to get to 700F.

Oddly the Thermoworks page for that probe says the cable is good up to 500F but the specs below that say "Cable: 14 to 221F" and "Transition (SST): Max temp 221F". What's the SST transition? Does that mean the plug? Anyway it works great and is well put together except the probe is 7" long, which may be a too long for most grills depending on installation. On the v4.2.2 board, every thermocouple I've tested has worked flawlessly so that really opens up the possibilities.

Other things I did last night

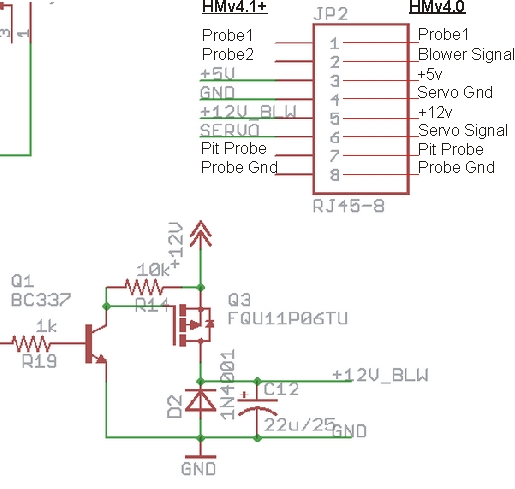

-- webui to switch blower output between "Pulse" and "Voltage". That's the best description I could come up with for the selection box.

-- Fixed some strict XHTML compliance in the conf page which took me for-friggin-ever to find and was causing Chrome to fail to render the page.

-- Added a hotkey (Alt-S on windows, Ctrl-S on Mac?) to the save button on the conf page so you don't have to scroll down to it any more.

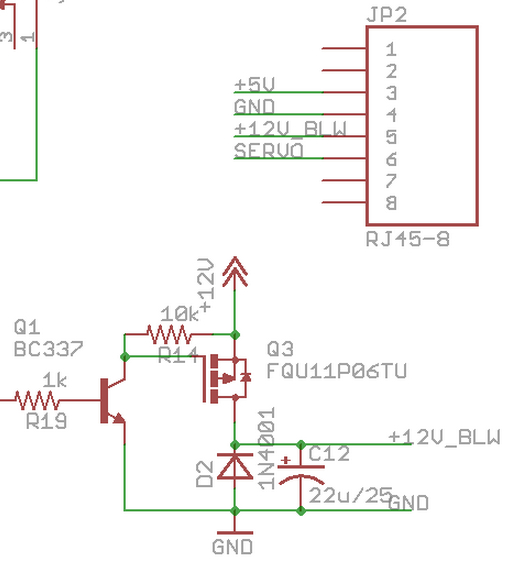

This morning I'm working on the 4.2 PCB and going to do a cross comparison of output % to fan speeds between Pulse and Voltage modes. Spoiler: at 50% on the existing v4.0/v4.1 designs you're getting roughly 10V, compared to 8.5V with the new TruVolt(tm) design (which 50% of the way between 5V and 12V). So the blower is a lot more precise now and expect to see it running more but maintaining temperatures better.

EDIT: Output comparison