Andrew F

TVWBB Super Fan

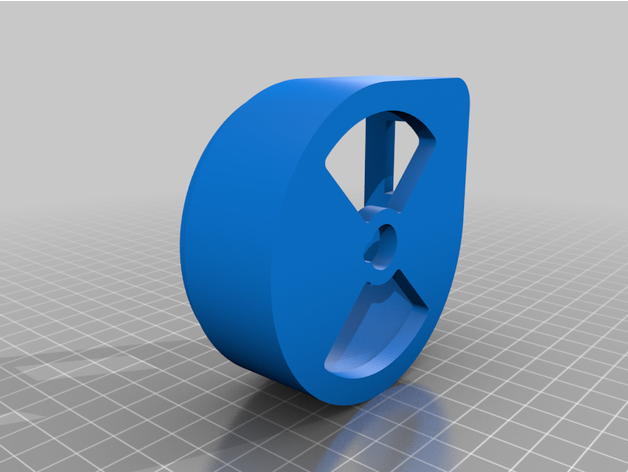

Did you put the Alum-a-damper abs print on Thingiverse? I have a printer on its way to me and my stupid large Adapt-a blower is starting to have problems opening and closing. I'm wondering if it is the extra large rotary plate with the smaller servo, or just the servo dieing.