John Bostwick

TVWBB Wizard

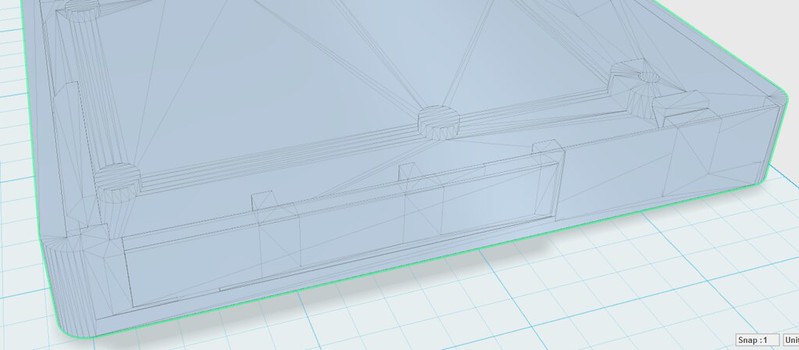

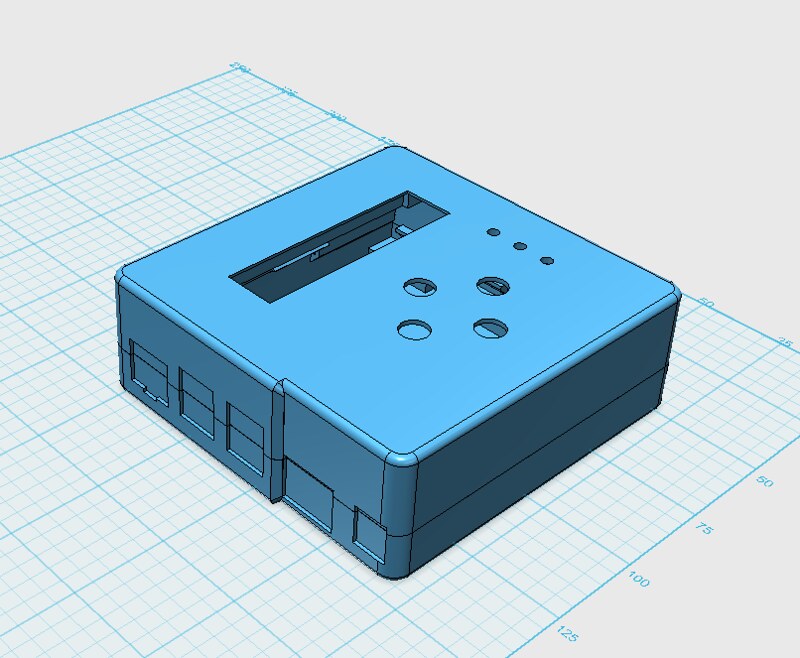

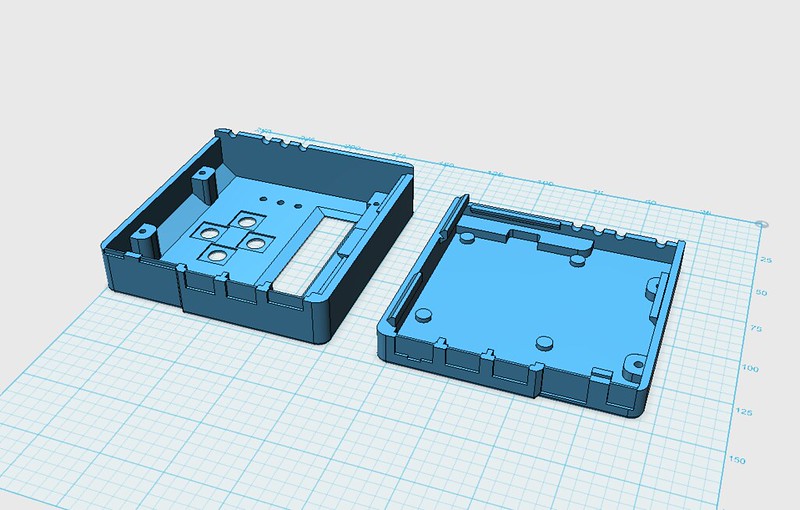

I printed a 4.2 case prior to this case without issue and then printed the 4.3 case. I have yet to get good results. Going to have to use ABS juice on this I think, as hairspray not working. whats making this case hard to print in ABS is the thickness of the walls. If you look at where its flat it corresponds to where its mostly flat and thin.