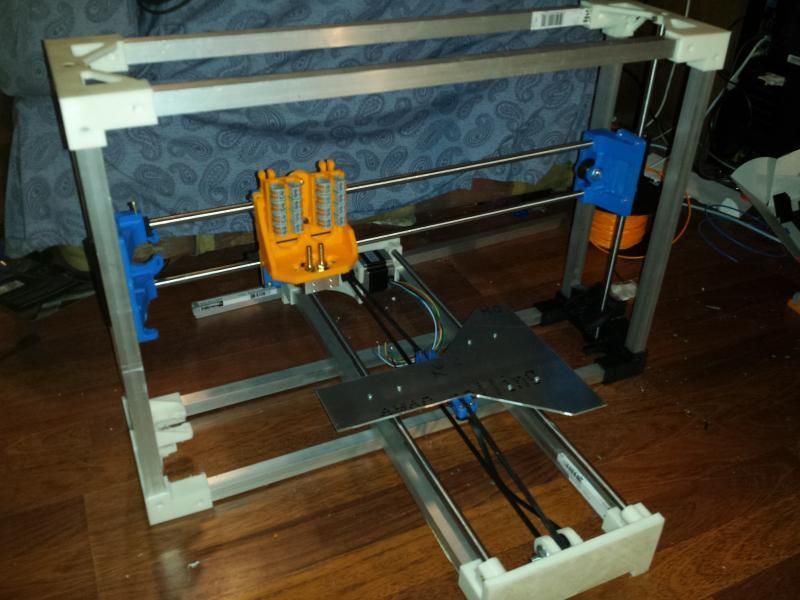

Brian - yep. bowden + coreXY will be fast. http://www.flickr.com/photos/116032124@N07/12243292086/ And yeah, the main advantage is no more moving bed. A secondary advantage is that the X and Y motors are sharing the load of moving the printhead, which should lead to fewer lost steps. Finally, the whole thing can be enclosed if you design it right.

Tom - Yeah, that'd be cool. I missed last years robot fest, and my daughter loves watching the printers make stuff so she'll dig the fest. CoreXY might be very doable with extrusion and openrail. Actually, VERY doable. Gotta go draw.

Tom - Yeah, that'd be cool. I missed last years robot fest, and my daughter loves watching the printers make stuff so she'll dig the fest. CoreXY might be very doable with extrusion and openrail. Actually, VERY doable. Gotta go draw.