UPDATE:

Received servo replacements. The nice thing about having multiple parts is the opportunity to do comparisons and troubleshooting. I noticed two things between the first and the replacement: 1) Difference in opacity. 2) There appears to be a small fracture in the plastic around the shaft. Difficult to discern without comparing side-by-side.

Notes:

a) The servo wiring sheath needed to be stripped. Punching down the wiring into the jack won't make a good contact.

b) I keep the servo barrel attached to the duct loose so there's less friction/work for the servo, and so the servo doesn't make a small buzzing noise.

b) The servo was acting like a dying bug and jumping around a lot. The ethernet cable might be to blame; I replaced the cable and the problem went away, but I was doing a lot of other troubleshooting that may have resolved the problem.

For the configuration and alignment, this is what I did:

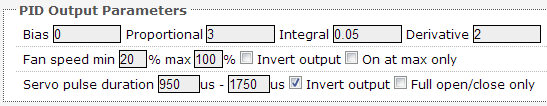

1) Set servo pulse duration 1000 - 2000, inverted.

2) With fan at 0%, attach the servo to the arm/fan housing so the housing duct is closed.

3) When you adjust the fan to 5%, you may notice the duct is not open. Adjust the pulse duration.

4) When you adjust the fan to 0%, you may notice the duct is not closed. Adjust the pulse duration.

At this point you'll have the pulse duration properly set and aligned for the closed position.

5) Adjust the fan to 100%.

6) You may notice the duct is not completely open, or too open. Adjust the pulse duration.