Staples to offer 3D printing next year, partners with Mcor.

Starting outside the USA but still pretty cool.

3D printer maker Mcor Technologies announced yesterday a new partnership with Staples to offer "Staples Easy 3D" -- a 3D printing service for customers. The service aims to offer ordinary people access to affordable, eco-friendly, high-quality and "photo-realistic" 3D printed products through Staples' retail stores.

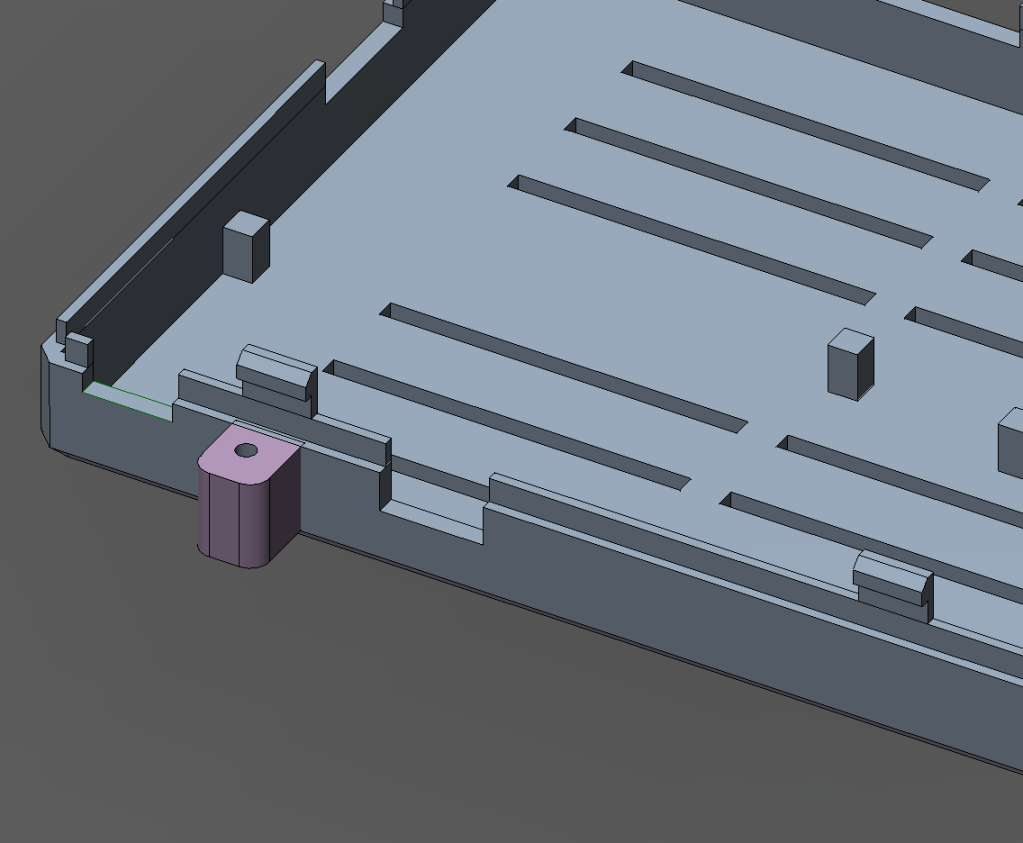

While there aren't many specifics on the service, we do know Staples stores will be equipped with Mcor's IRIS printing system -- a commercial 3D printer known for its high color capabilities and low operational costs. IRIS uses proprietary inks, water-based adhesives and regular office paper to print solid, three-dimensional objects.

Admittedly, that sounds a bit like a sophisticated paper mache (which isn't necessarily a bad thing), but it's likely the first step toward more robust 3D print solutions. Sturdier materials like thermoplastic resin and advanced processes like metal laser stintering could be the next steps forward.

The potential disruptive nature of 3D printing science-magic can't be overstated. Being able to instantly produce useful objects will change lives, economies and society as we know it. Given a high enough level of printer sophistication, a future where any person can download schematics to just about anything and have it printed at a local store isn't inconceivable.

Think about this: Today's 3D print systems are capable of producing parts for functional firearms. With the advent of 3D printable guns upon us, what happens to gun control laws? Will printers be regulated like guns? The print materials, perhaps? These are just a couple questions about a single topic -- there will be far more controversy than just guns. Take the Pirate Bay's interest in offering schematics to "physibles", for example. In the future, such a notions could make "piracy" more palpable than ever.

Mcor states that Staples Easy 3D will launch first in the Netherlands and Belgium early next year. Afterward, Mcor expects the service to be "quickly" rolled out to other countries.