You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HM version 4 Rpi 3d print case

- Thread starter Tom Kole

- Start date

Kyle Christensen

TVWBB Fan

I think most of us are just waiting patiently for someone to start taking orders.

Waiting on plastic to show up.

There is nothing more frustrating than having a 3D printer and no filament to print with.

If all goes well it should be here mid-week.

@ stan, I haven't printed the 1/31 case yet, and I wouldn't advise you to do so either. I got some feedback on the printed case and am making some sizing adjustments. I will update the source and .stl's and let the forum know once they are uploaded.

Also thinking about incorporating some additional case "enhancements", mostly aesthetic.

Matt

There is nothing more frustrating than having a 3D printer and no filament to print with.

If all goes well it should be here mid-week.

@ stan, I haven't printed the 1/31 case yet, and I wouldn't advise you to do so either. I got some feedback on the printed case and am making some sizing adjustments. I will update the source and .stl's and let the forum know once they are uploaded.

Also thinking about incorporating some additional case "enhancements", mostly aesthetic.

Matt

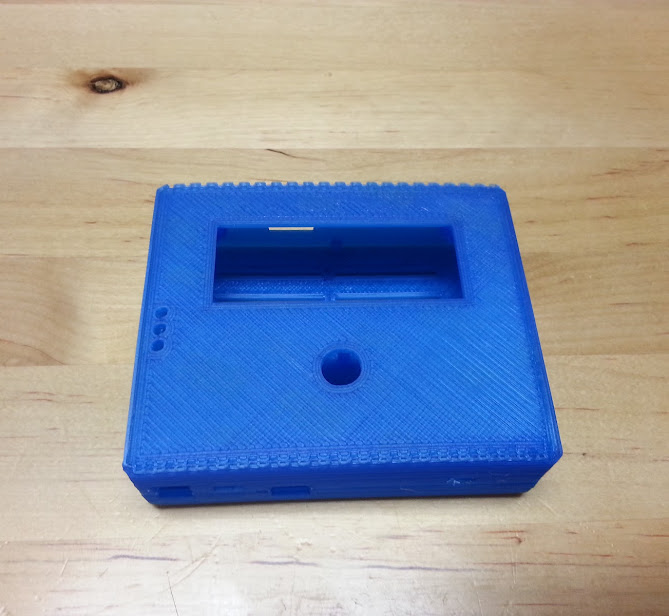

I am picking up my case today at 11am or so from a local source. I had the OG case from http://tvwbb.com/showthread.php?36661-HM-version-4-Rpi-3d-print-case&p=366115&viewfull=1#post366115 printed. I figure it will be a fine case until a more tweaked version is printed and confirmed by people. Since it was only $25 to print I am happy. Got it done in blue!

Can you share your local source? I may be interested in getting another printed up.

thanks,

dave

thanks,

dave

I am picking up my case today at 11am or so from a local source. I had the OG case from http://tvwbb.com/showthread.php?36661-HM-version-4-Rpi-3d-print-case&p=366115&viewfull=1#post366115 printed. I figure it will be a fine case until a more tweaked version is printed and confirmed by people. Since it was only $25 to print I am happy. Got it done in blue!

Can you share your local source? I may be interested in getting another printed up.

thanks,

dave

Go to http://www.makexyz.com. Select 'Print Your Design'. Upload your stl file. In the zip code select 78759, PLA, and either select red, green, clear, or blue to be able to have an option to pickup locally. If you want different colors, it can be shipped.

I am picking mine up from the printer in the Arboretum to save on shipping. I also got in contact with the owner of the site and I felt comfortable with the process and himself. He allows people to list their printers and then based on the zip you enter, selects the a closet printer and gets a cost for the print.

Other people not in Austin can use the service and just have it shipped. Seems to be a better deal than Shapeways.

Can you share your local source? I may be interested in getting another printed up.

thanks,

dave

Dave,

I got my case and overall it is pretty good. It is definitely not the quality of the Shapeways, but it works okay. The only major issue i have is the tabs are not sturdy and have already mostly broken. I am going to reinforce with some super glue (when I can find it). If I were to do it over, I would print one of the cases that uses screws instead. Then I would have no problems. I will post pictures later today.

Dave,

I got my case and overall it is pretty good. It is definitely not the quality of the Shapeways, but it works okay. The only major issue i have is the tabs are not sturdy and have already mostly broken. I am going to reinforce with some super glue (when I can find it). If I were to do it over, I would print one of the cases that uses screws instead. Then I would have no problems. I will post pictures later today.

Here are some pics of the printed case: https://plus.google.com/photos/1107...ms/5841614194607788497?authkey=CNPO5OGquJ-oaw

I should take some pics of the insides- I will do that later.

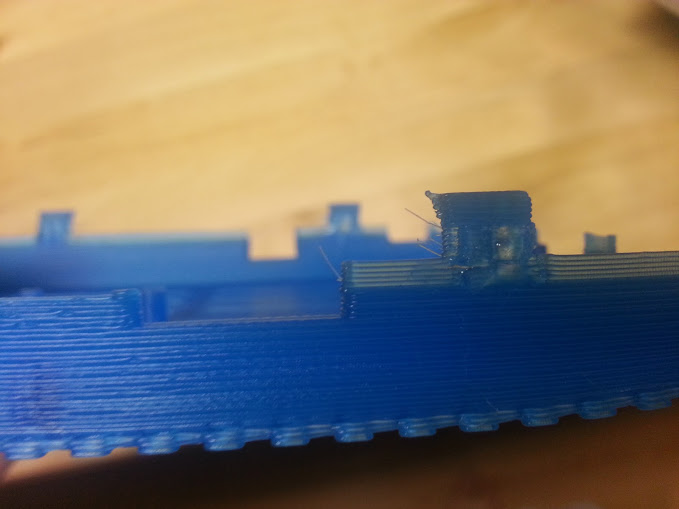

It looks like the bottom came off the print bed at the corners during the print causing it to warp.

I added a few more pics to the link above. But here is one close up shot:

It looks like he also put down a support layer underneath and didn't take it off. I can't believe who ever printed that had the nerve to charge you.

I looked at that print and cringed a little.

It looks like PLA, but PLA doesn't usually warp like that, especially with the thin walls that the case has. ABS will warp like that if the part isn't printed in a bath of warm air.

I'll bet the problem (and why the PLA warped) has to do with print speed. The case was probably printed very slowly - he/she was concerned about printing the tabs correctly, which is very difficult to do at higher speeds. There are ways around this, but may involve editing the g-code used for printing.

Jason, you should go back and talk to the fella who printed you the case. See if he'd be willing to print you another one, or at least ask why there is so much warping at the corners.

Matt

It looks like he also put down a support layer underneath and didn't take it off. I can't believe who ever printed that had the nerve to charge you.

I know absolutely zilch about 3D printing. So I can't tell that it was that bad ect. All I know is it formed a solid case, fit together reasonably well. I hope the HeaterMeter fits properly. I did take the extra bottom case and drill holes in it and used zip ties to bring it together and it seems to be very sturdy. It was printed using a http://printrbot.com/ PrintrBot Jr.

Alan Erickson

TVWBB Fan

A little heads up on the 3D printing (and I'm no expert either so anyone can correct me), but there have been two different technologies used to print the cases. The first is Selective Laser Sintering (SLS), which is described here:

http://en.wikipedia.org/wiki/Selective_laser_sintering

and is shown in this youtube clip:

http://www.youtube.com/watch?v=gbtu3wBJ-pY (pretty cool)

This is the technology that Shapeways used for the cases that were shown here. It's more expensive, but it also has greater precision / accuracy. The model that you printed was drawn / created with this technology in mind.

There's also Fused Deposition which is described here:

http://en.wikipedia.org/wiki/Fused_deposition_modeling

It's less expensive, but it doesn't offer the precision that the sintered does.

One of the members here tried making a case with their own fused deposit equipment:

http://tvwbb.com/showthread.php?36661-HM-version-4-Rpi-3d-print-case/page12

but they also had trouble with the tabs so they went to a screw together case like the one shown here:

http://tvwbb.com/showthread.php?36661-HM-version-4-Rpi-3d-print-case/page14 (also pretty cool)

So.....with all that being said there has been a little fork in the 3D printed case model design. One is for the sintered, the other for the deposit. I haven't been following the deposit design in this thread much, but the last I read the design was still being adjusted a little bit. If you have the case re-printed or want / need to make another, you may want to look at using the screwed design instead of the tabbed one.

http://en.wikipedia.org/wiki/Selective_laser_sintering

and is shown in this youtube clip:

http://www.youtube.com/watch?v=gbtu3wBJ-pY (pretty cool)

This is the technology that Shapeways used for the cases that were shown here. It's more expensive, but it also has greater precision / accuracy. The model that you printed was drawn / created with this technology in mind.

There's also Fused Deposition which is described here:

http://en.wikipedia.org/wiki/Fused_deposition_modeling

It's less expensive, but it doesn't offer the precision that the sintered does.

One of the members here tried making a case with their own fused deposit equipment:

http://tvwbb.com/showthread.php?36661-HM-version-4-Rpi-3d-print-case/page12

but they also had trouble with the tabs so they went to a screw together case like the one shown here:

http://tvwbb.com/showthread.php?36661-HM-version-4-Rpi-3d-print-case/page14 (also pretty cool)

So.....with all that being said there has been a little fork in the 3D printed case model design. One is for the sintered, the other for the deposit. I haven't been following the deposit design in this thread much, but the last I read the design was still being adjusted a little bit. If you have the case re-printed or want / need to make another, you may want to look at using the screwed design instead of the tabbed one.

Jarrod Igou

TVWBB Member

I think most of us are just waiting patiently for someone to start taking orders.

Bingo!

Alan,

you are essentially correct.

Tom's original design is perfect to be printed by a service bureau, like shapeways or imaterialize. They can reproduce very finely detailed parts, at a price.

Reprap, or FDM (Fused Deposition Modeling) or Additive Manufacturing cannot reproduce the same level of accuracy as the technology currently lacks the resolution compared to SLS. That is not to say that FDM cannot produce reliable, robust components. They just have to be designed a little differently to match the capabilities of the output device. So walls need to be a little thicker, features cannot be as fine, structures cannot 'free-air' without support (some new powder printers are capable of this, but they are a little ways off for the average hobbyist) and there are some general design rules that must be followed for a successful print.

For example, I sent a case to be fitted to the components as I don't have those yet.

http://s1014.beta.photobucket.com/user/mtdew456/library/Heatermeter Prototype Case

Some minor changes need to be made, but they are in the works.

So I've got some things to print off for my daughters birthday party, but once that is done I'll print off cases for anyone who wants one.

I just got a shipment of plastic in today - black, red, ivory/white, silver and orange.

You pick the color.

You pick the hardware (standard or metric)

Footed or non-footed.

$25 per case + $5 for shipping via usps flat rate small box (cost is like $5.08 or something) $25 is what I have to charge as it's cost plus $10 which is what I like to call the "wife tax." If my hobby isn't in the black she starts to get...upset.

And I'll send you images of your printed case so you can approve it before I send it. This way you know exactly what you're getting.

Just message me if you want one.

Matt

you are essentially correct.

Tom's original design is perfect to be printed by a service bureau, like shapeways or imaterialize. They can reproduce very finely detailed parts, at a price.

Reprap, or FDM (Fused Deposition Modeling) or Additive Manufacturing cannot reproduce the same level of accuracy as the technology currently lacks the resolution compared to SLS. That is not to say that FDM cannot produce reliable, robust components. They just have to be designed a little differently to match the capabilities of the output device. So walls need to be a little thicker, features cannot be as fine, structures cannot 'free-air' without support (some new powder printers are capable of this, but they are a little ways off for the average hobbyist) and there are some general design rules that must be followed for a successful print.

For example, I sent a case to be fitted to the components as I don't have those yet.

http://s1014.beta.photobucket.com/user/mtdew456/library/Heatermeter Prototype Case

Some minor changes need to be made, but they are in the works.

So I've got some things to print off for my daughters birthday party, but once that is done I'll print off cases for anyone who wants one.

I just got a shipment of plastic in today - black, red, ivory/white, silver and orange.

You pick the color.

You pick the hardware (standard or metric)

Footed or non-footed.

$25 per case + $5 for shipping via usps flat rate small box (cost is like $5.08 or something) $25 is what I have to charge as it's cost plus $10 which is what I like to call the "wife tax." If my hobby isn't in the black she starts to get...upset.

And I'll send you images of your printed case so you can approve it before I send it. This way you know exactly what you're getting.

Just message me if you want one.

Matt

Alan,

For example, I sent a case to be fitted to the components as I don't have those yet.

http://s1014.beta.photobucket.com/user/mtdew456/library/Heatermeter Prototype Case

Some minor changes need to be made, but they are in the works.

So I've got some things to print off for my daughters birthday party, but once that is done I'll print off cases for anyone who wants one.

I just got a shipment of plastic in today - black, red, ivory/white, silver and orange.

You pick the color.

You pick the hardware (standard or metric)

Footed or non-footed.

$25 per case + $5 for shipping via usps flat rate small box (cost is like $5.08 or something) $25 is what I have to charge as it's cost plus $10 which is what I like to call the "wife tax." If my hobby isn't in the black she starts to get...upset.

And I'll send you images of your printed case so you can approve it before I send it. This way you know exactly what you're getting.

Just message me if you want one.

Matt

Good gosh that case looks sooo much better than the one I had printed.... Today I hope to finish the build and see how it fits in the case I got. If it doesnt work at all, I will take you up on that offer!

Alan,

http://s1014.beta.photobucket.com/user/mtdew456/library/Heatermeter Prototype Case

/QUOTE]

That looks really good! Will you post the plans you did this with? And what 3D printer are you using?

The files are up on my github. Both the source files and the .stl's. If they aren't manifold just run them through netfabb cloud service to fix them.

The 1.5 case still has a few changes to be incorporated into it. I meant to update the case a while ago, but been too busy to do so. That should be remedied by tonight, so the files will change slightly to better fit the components. Tom has already done some of this work, I just need to incorporate the feedback I got about the printed case.

And the printer, it's a Prism Mendel 1.5.

Matt

The 1.5 case still has a few changes to be incorporated into it. I meant to update the case a while ago, but been too busy to do so. That should be remedied by tonight, so the files will change slightly to better fit the components. Tom has already done some of this work, I just need to incorporate the feedback I got about the printed case.

And the printer, it's a Prism Mendel 1.5.

Matt

Last edited:

Well I got the heatermeter assembled tonight. This case sucks. The hole for the 4 way button is oblong and not a nice circle and therefore I can not push to the right. I had to shave the lcd slot to get the lcd to fit. Hdmi didnt fit so I had to shave that down too. Holes for the LED are too small. Anyways.... Im going to need a better case when they are being printed here

Last edited: