Peter F

TVWBB Fan

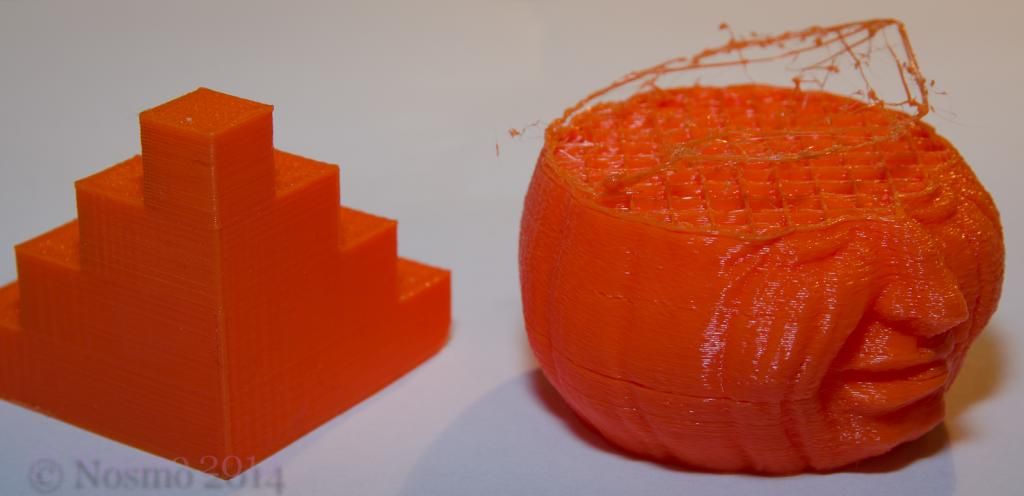

Funny that you mention the filament as possible cause, the blue and black filaments are the cheapest that I could find, and the orange filament is the way to expensive and highly recommend (on one of the Dutch tech forums) "Dutch Filaments PLA", but I guess that price alone is not the only indication of quality. I'll check the Dutch forum for recommend temps.

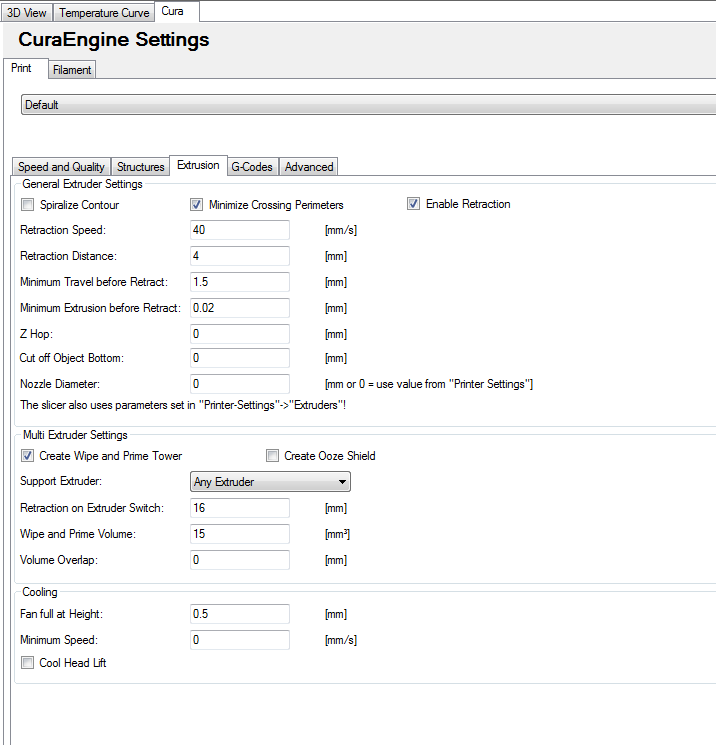

I have been playing with the speed settings so i might have screwed something up, will go back to default speeds and try again. Haven't touched the retract settings yet so I'm not sure if this is on or off.

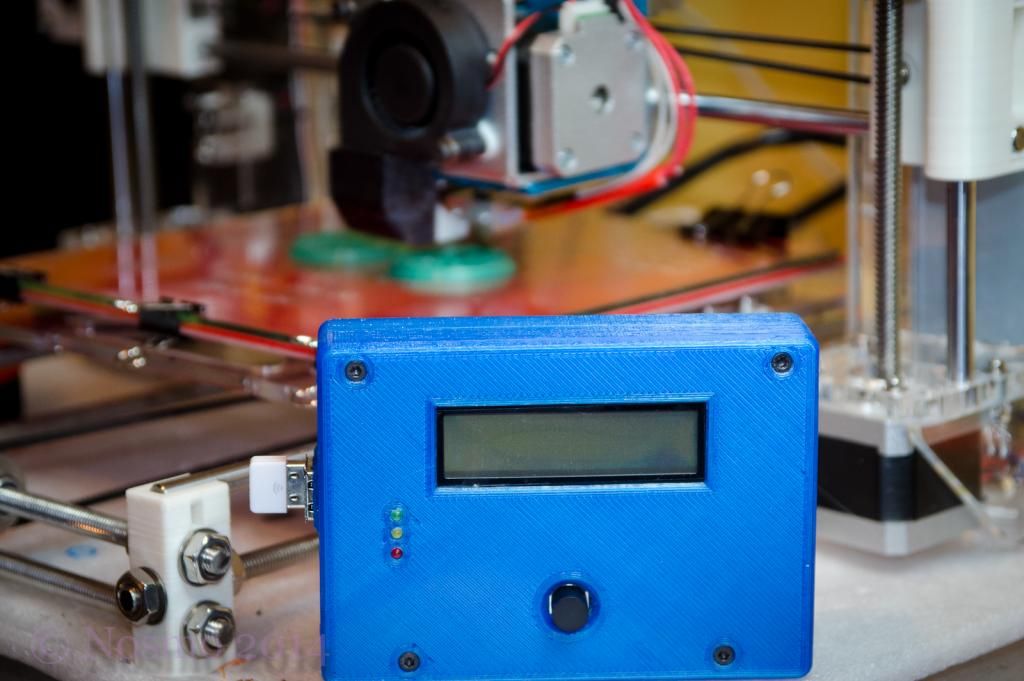

This 3D business is not so easy as it looks, lots to learn!

I have been playing with the speed settings so i might have screwed something up, will go back to default speeds and try again. Haven't touched the retract settings yet so I'm not sure if this is on or off.

This 3D business is not so easy as it looks, lots to learn!