Bryan Mayland

TVWBB Hall of Fame

No kidding. I still love my MakerFarm i3, but this looks like an even more complete kit. Includes an aluminum bed, power supply, glass printing surface, and a spool of filament for $100 less than I paid? Nice.

I'm also loving OpenSCAD. I'm sure a lot of people must like drawing 3D things using a mouse but the technical side of me really enjoys just telling the CAD program what I want. It seems a lot more intuitive to me to tell the program "I would like a 10x15x5 box then on the end of that box make a 3.2 radius cylinder, but subtract a square hole all the way through it" than trying to click my way through it. Especially when you decide you want that cylinder to be 0.5mm inset rather than right on the edge and all it takes is 2 seconds of typing rather than trying to select just what you want and not "no not that edge too, why are you moving that piece too?". Also programmatically being able to change holes to polygon holes that are calculated to be just the right size you want them to end up is a lot easier.

The iterative process of 3D Printing is great. Design something, print it out, see how it interacts in the real world, redesign. Each time I print something and play with it, I get a new idea how to make it better. Still a ways to go on this but it is coming along

I'm also loving OpenSCAD. I'm sure a lot of people must like drawing 3D things using a mouse but the technical side of me really enjoys just telling the CAD program what I want. It seems a lot more intuitive to me to tell the program "I would like a 10x15x5 box then on the end of that box make a 3.2 radius cylinder, but subtract a square hole all the way through it" than trying to click my way through it. Especially when you decide you want that cylinder to be 0.5mm inset rather than right on the edge and all it takes is 2 seconds of typing rather than trying to select just what you want and not "no not that edge too, why are you moving that piece too?". Also programmatically being able to change holes to polygon holes that are calculated to be just the right size you want them to end up is a lot easier.

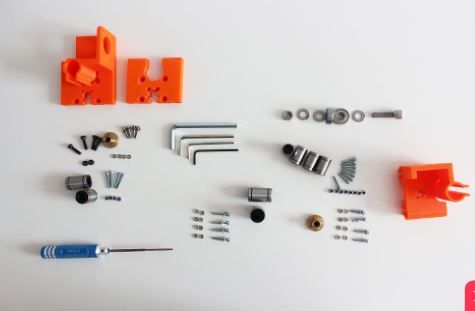

The iterative process of 3D Printing is great. Design something, print it out, see how it interacts in the real world, redesign. Each time I print something and play with it, I get a new idea how to make it better. Still a ways to go on this but it is coming along