I'm getting a bit frustrated by the lack of ability to control temps due to air infiltration. This is particularly true if there is any wind at all. I think the lower vents seal well so I'm going to work my way from the bottom up.

I got some Permatex "HIGH-TEMP RED RTV SILICONE GASKET MAKER" from a local auto parts store. Yes, not food grade and yes, I'm aware of the warnings that it produces formaldehyde at higher temps.

In this application it will not have contact with food, so I don't think food grade is important.

The formaldehyde issue does concern me. I did lookup the MSDS for the food grade product and it carries the same warning, so that is no solution. After this cures, I will run one empty smoke with the thought that it will release the bulk of any formaldehyde that will eventually be released. I will then follow this by airing out the WSM and I might even use oven cleaner to remove the coating inside the shell in case any material has been absorbed into that.

Needless to say, I appreciate any further information anyone can provide regarding this concern. I also plan to contact Permatex to see what they say.

I applied a small bead along the bottom groove on the middle section. When this is set into the base (after curing of course), it should provide a good seal between the two parts.

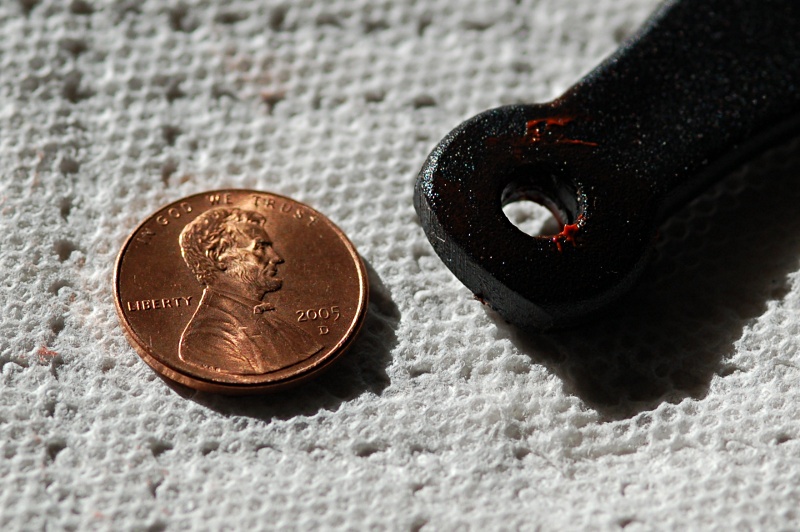

I used the handle of a silicone brush - slightly modified to increase the radius - to form the bead after squeezing it into the groove. Anything that can be appropriately shaped could probably be used.

(Foreign readers - the US penny used for scale is about 3/4", 19mm diameter.)

After giving the silicone about 20 minutes to firm up, I gently scraped the extra off.

Comments and questions?

-walt

I got some Permatex "HIGH-TEMP RED RTV SILICONE GASKET MAKER" from a local auto parts store. Yes, not food grade and yes, I'm aware of the warnings that it produces formaldehyde at higher temps.

In this application it will not have contact with food, so I don't think food grade is important.

The formaldehyde issue does concern me. I did lookup the MSDS for the food grade product and it carries the same warning, so that is no solution. After this cures, I will run one empty smoke with the thought that it will release the bulk of any formaldehyde that will eventually be released. I will then follow this by airing out the WSM and I might even use oven cleaner to remove the coating inside the shell in case any material has been absorbed into that.

Needless to say, I appreciate any further information anyone can provide regarding this concern. I also plan to contact Permatex to see what they say.

I applied a small bead along the bottom groove on the middle section. When this is set into the base (after curing of course), it should provide a good seal between the two parts.

I used the handle of a silicone brush - slightly modified to increase the radius - to form the bead after squeezing it into the groove. Anything that can be appropriately shaped could probably be used.

(Foreign readers - the US penny used for scale is about 3/4", 19mm diameter.)

After giving the silicone about 20 minutes to firm up, I gently scraped the extra off.

Comments and questions?

-walt