James_Brouillette

New member

So just got all my stuff in the other day (thanks Bryan for the soldering! and all you do )

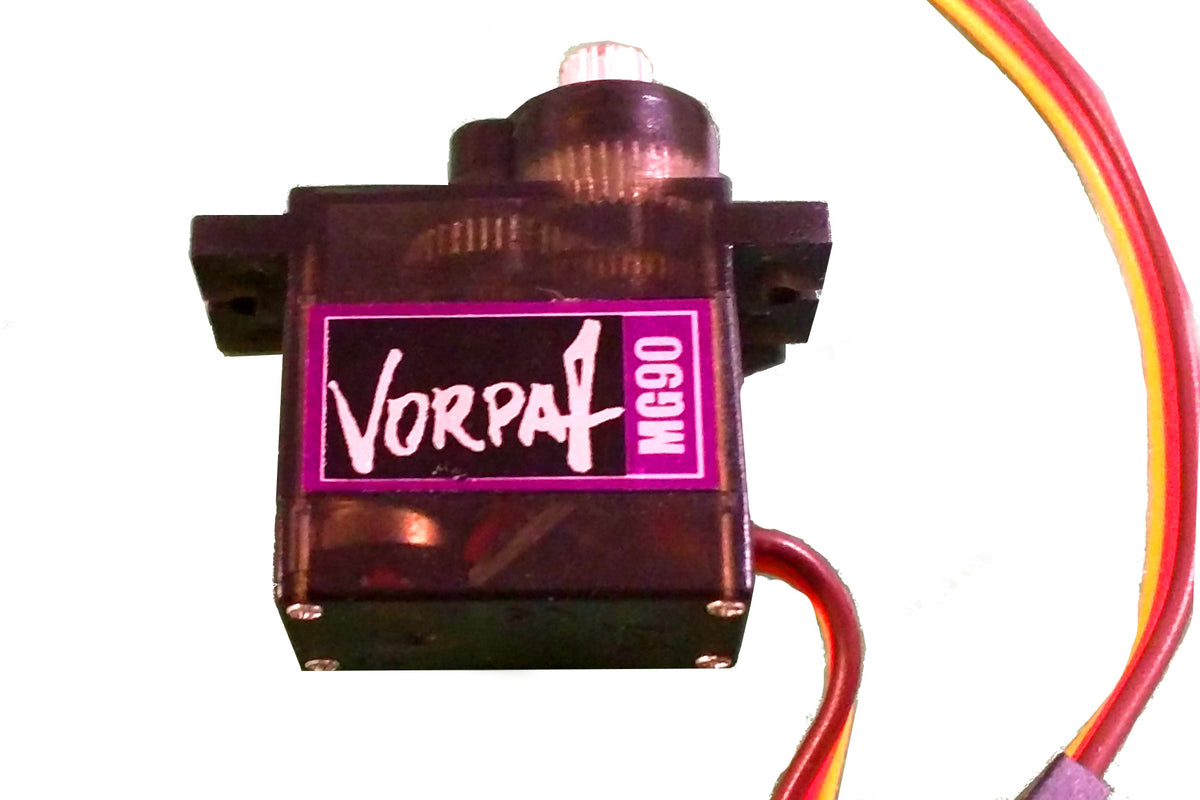

And it works !!! , one slight issue , it seems the servo whines all the time is this normal ? is it going to burn out ? I've repunched down the keystone a few times to be sure i didnt' cross a wire or something causing interference or feedback . I did pickup a spare servo on amazon i've not tested that one yet . I need to find a shorter Ethernet cable , could it be the 6 foot length cat6 cable causing it ?

You will notice in the video if it tap it or jiggle it , it seems to stop or lesson almost like its binding but its not ..

it is working perfectly just wondered before i start using this on a 10 hour cook if this is safe ? and well its a bit annoying of a sound .

Please watch video so see it in action and hear it .

Also one other slight thing , is it normal for a uncalibrated k-type read a bit high and climb in temp when first starting up .. after i turn on the heatermeater temp seems to slowly raise a few 10ths of a degree every min .. it eventually does seem t stabilize . I'm getting another k-type in, in a few days and will test that one , this one will be sealed so i can properly test it in boiling water and calibrate it , the one i have now is exposed and i dont' think its a good idea to dunk in water and risk water seeping into the braided part.

Anyways thanks guys for all your help and hopefully the video better shows the issue .

And it works !!! , one slight issue , it seems the servo whines all the time is this normal ? is it going to burn out ? I've repunched down the keystone a few times to be sure i didnt' cross a wire or something causing interference or feedback . I did pickup a spare servo on amazon i've not tested that one yet . I need to find a shorter Ethernet cable , could it be the 6 foot length cat6 cable causing it ?

You will notice in the video if it tap it or jiggle it , it seems to stop or lesson almost like its binding but its not ..

it is working perfectly just wondered before i start using this on a 10 hour cook if this is safe ? and well its a bit annoying of a sound .

Please watch video so see it in action and hear it .

Also one other slight thing , is it normal for a uncalibrated k-type read a bit high and climb in temp when first starting up .. after i turn on the heatermeater temp seems to slowly raise a few 10ths of a degree every min .. it eventually does seem t stabilize . I'm getting another k-type in, in a few days and will test that one , this one will be sealed so i can properly test it in boiling water and calibrate it , the one i have now is exposed and i dont' think its a good idea to dunk in water and risk water seeping into the braided part.

Anyways thanks guys for all your help and hopefully the video better shows the issue .

Last edited: