I can't recall if you tried a different servo? That may be worth a shot... With such a long cable the quality of the ends and crimp are very important, I've had some cables perform well and others not. I have hand crimped my cable, its about 50ft long and has been working without jitters for years now. (It is older CAT5e solid 24 gauge cable, this week I wired a network with a new spool of CAT6e cable and the wires seemed very thin compared to what I have at home) If you hand crimp make sure you follow the standard CAT5 wiring scheme, when putting this together I found if you choose wires at randum there will be crosstalk interference. I spent a lot of time working out the wiring scheme that works best, you need keep certain wires in twisted pairs to cancel crosstalk.

That said, on my last two cooks I have had a slight bit of jitter, which is unusual. I checked the cable and CAT5 jack at the RD3 and it looked good so I chalked it up and assumed the servo which has been out in the weather and powered on for close to two years is just failing. I haven't gotten around to swapping out the servo yet, I will report back when I do if my jitters go away.

It is also possible that a firmware change of how active the servo is may be involved here (how small of increments the servo moves in, rest period etc), not sure if Bryan made any changes in the servo movement lately? I am running the snapshot release loaded a couple weeks ago. Previously I have had a very long run with no servo jitter on this same cable. It is also possible that I need to recrimp the outside end, that needs to be done every couple years of being exposed to weather. So I have a little jitter troubleshooting to do right now myself, will report back if I come up with any unusual findings.

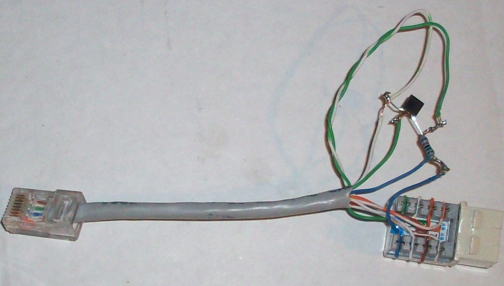

When I first started experimenting with long cables I had trouble with the servo flaking out badly so I put together a servo booster circuit which eliminated the issue. I posted a thread about it at the time which can be found

here, there is a video there showing an original roto damper with and without the booster. You will hear some jitter (buzzing) in that video, this is due to drag on the servo from wires, a problem enherent with the original RD design, the RD3 eliminates moving the blower and wires to eliminate this drag on the servo and related jitter. I shared my findings with Bryan and asked that he add it to the HM build, he did end up adding a different version of a servo booster on the HM board which is still present today. However, in my experiments with a long cable my circuit was more effective. If you feel like experimenting you can build it up pretty cheap. (you can use it inline with the CAT5 cable and booster that on the HM board without issue)