Robert Clark

TVWBB Pro

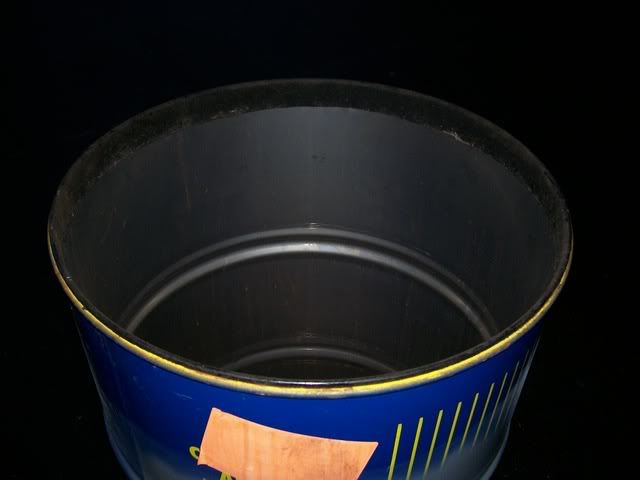

Doing a test burn now. Holding at 225 - 250 pretty constant.

Originally posted by James H:

Nice job....Can I ask if those nozzles on the bottom are the air vents? if not, what purpose?

thanks.

James

Originally posted by patrick sullivan:

Does the Weber top fit perfectly on a barrel, or did you have to do some mod to it?

Pat

Originally posted by Brian Berz:

Looks great - Did you build it or buy it?

Originally posted by Robert Oleksak:

Robert your drum kinda looks like mine. Nice job your gonna love it. I have a total of $12.00 invested in mine.

Originally posted by Brian Moriarty:

Nice job on the drum!

Just a heads up for future builds, here is what I do instead of cutting the lip off the drums.

I sacrifice the top 1.5" of the kettle bowl and make a flange that will fit in either an open or closed drum, allowing me to use the drum lid or Weber lid securely.

Originally posted by Joe Lanier:

Im inspired! do those smokers use a water pan? If so, what do you use for one?