Rusty James

TVWBB Emerald Member

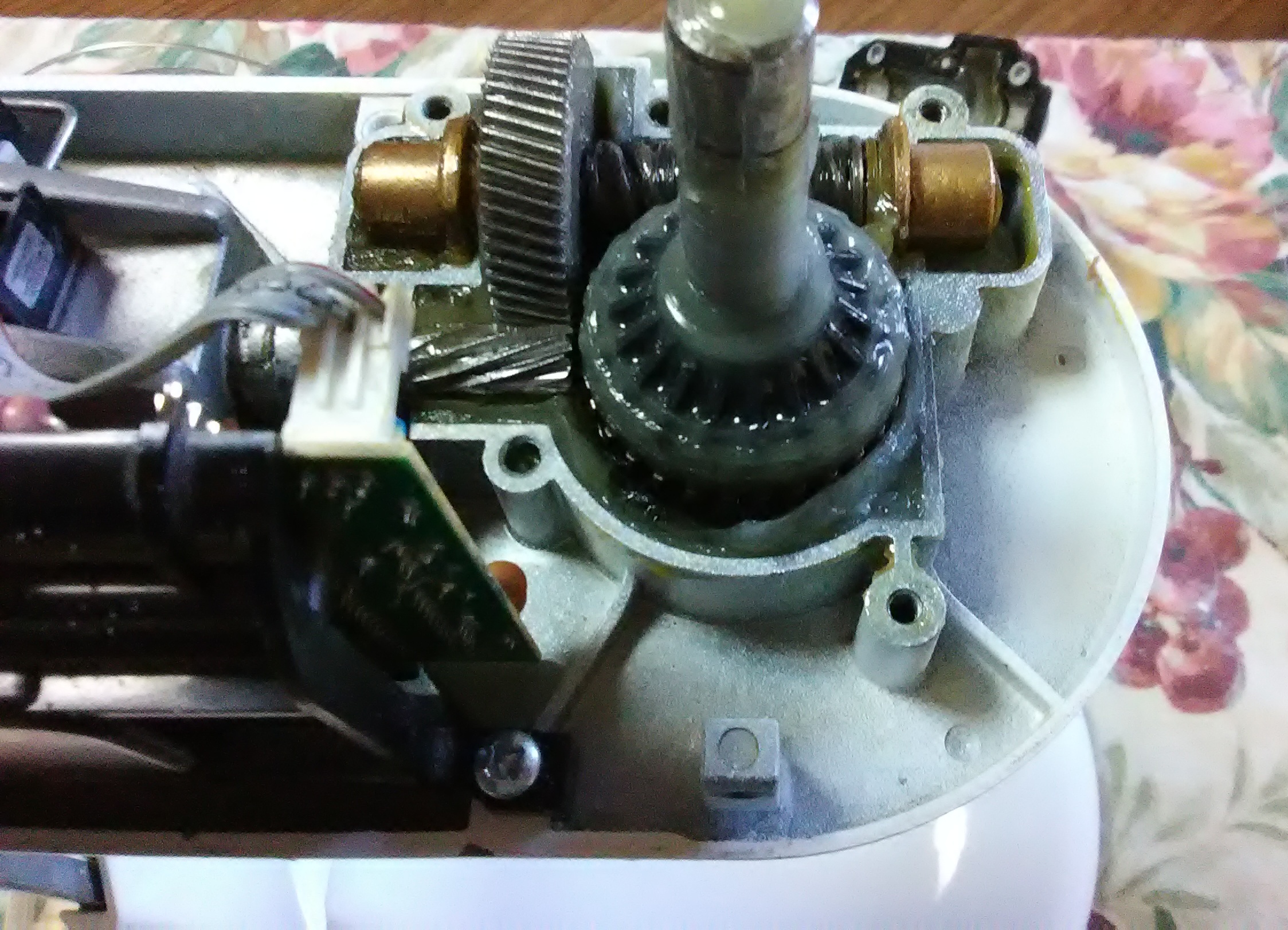

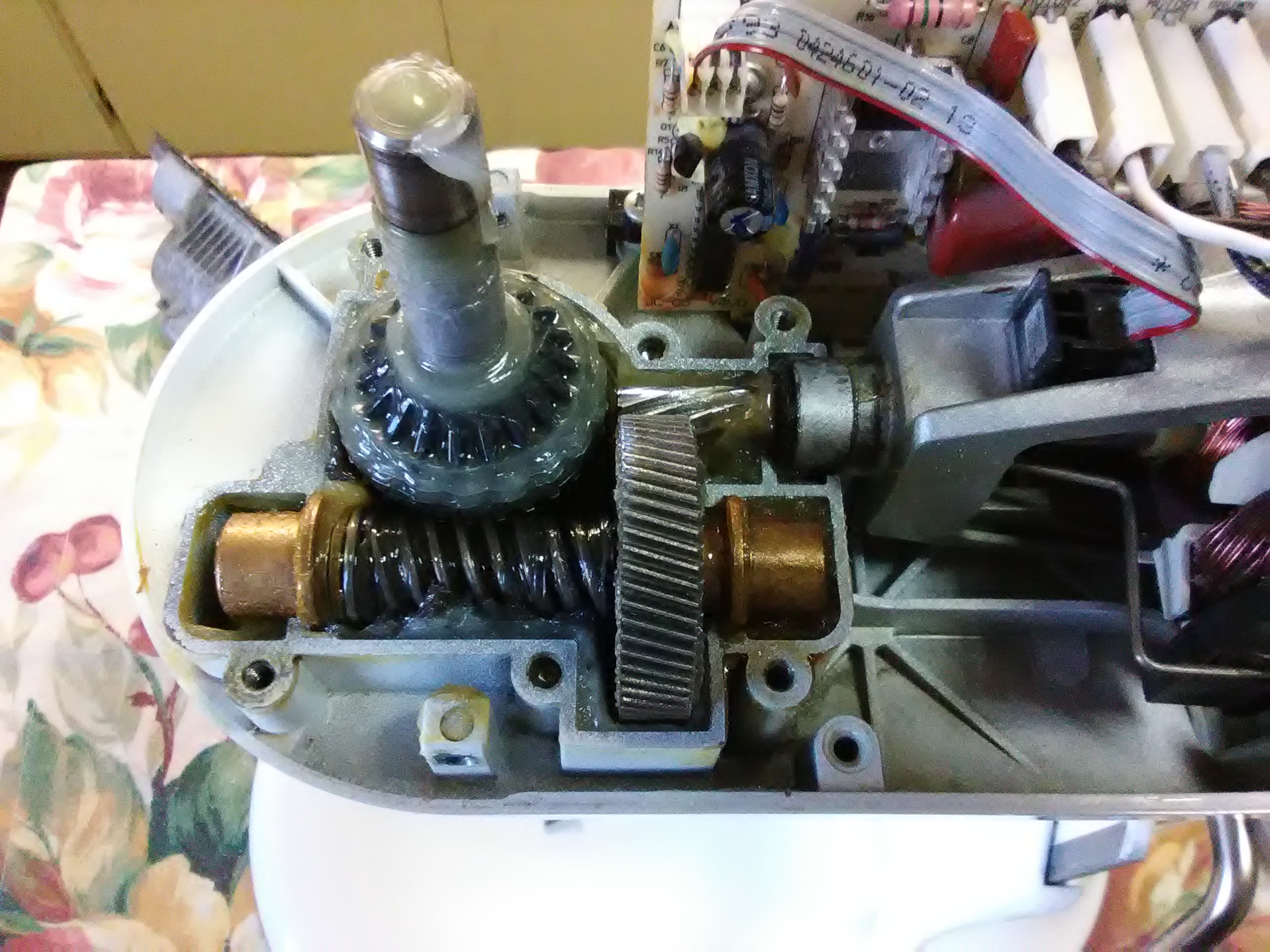

Here's part two if anyone is interested...

You can't go wrong with the KA. You see them in more professional kitchens than just about anything else (save for Hobart) but generally KA is what they have for their counter top machines

The pizza turned out nice! Some of the best crust I've made so far.

For what it's worth, I load my pizzas up with at least 8 ounces of cheese, 8 ounces of sausage, half a pack of pepperoni, half a bell pepper, half a can of olives, half a pint of mushrooms (lol), etc.

Now let's see how you pick up a slice of that pizza.