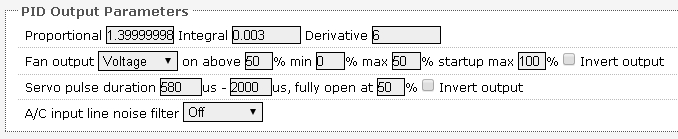

I started up a dry run cook a bit ago on the Akorn so I can share some details and examples of the concepts I mentioned above. My HM config currently is as shown below:

This is my dual purpose setup that can handle both low and slow and high heat cooks without tweaking the HM settings between the two. As you can see I have the duty split between the servo damper and fan at 50%, it is damper only up to 50%, the fan kicks in at 50% and ramps to its MAX value at 100%. For low and slow, during the cook the HM output stays below 50% and the fan never runs. For high heat cooks the HM output runs past 50% so the damper opens up fully and the fan stokes and controls the fire, the damper functions only to tamp down overshoot.

I start the fire differently depending on the target temp for the cook...

If I were doing high heat I would put a large load of lump coal in the burn pan and light 1 weber starter cube (or two if I was impatient) under the center of the pile. I would let the fire burn with the lid open until the white smoke from the weber cubes as subsided and quite a bit longer if I were shooting really high like for pizza, or close the lid sooner if I where shooting for steaks or roasting etc. Getting to know your grill and how much fire it takes to achieve various temps is important, I think it's a good idea to learn the grill with a few manual cooks before you add the HM to the mix, this makes things easier to suss out when you are setting up your HM rig.

I've found in general with the HM the more the blower has to work to achieve the target temp the more forgiving it is to things like PID settings, vent settings, fire size etc... and therefore high temps are easier to nail than low and slow, and low and slow is easier to nail with a small crack in the top vent and the fan blowing. The damper only low and slow cook would be the most difficult to nail but IMHO it is the best method from the cooking perspective, because cool air isn't being forced into the pit causing more fuel to burn and smoke to roll around the pit a while before it gets pushed out the cracked open top vent. With damper only convection control the top and bottom vents are opened more evenly and there is less air flow overall, so less drying of food, less fuel burned, and smoke moves more freely out of the pit making the smoke around your food fresher.

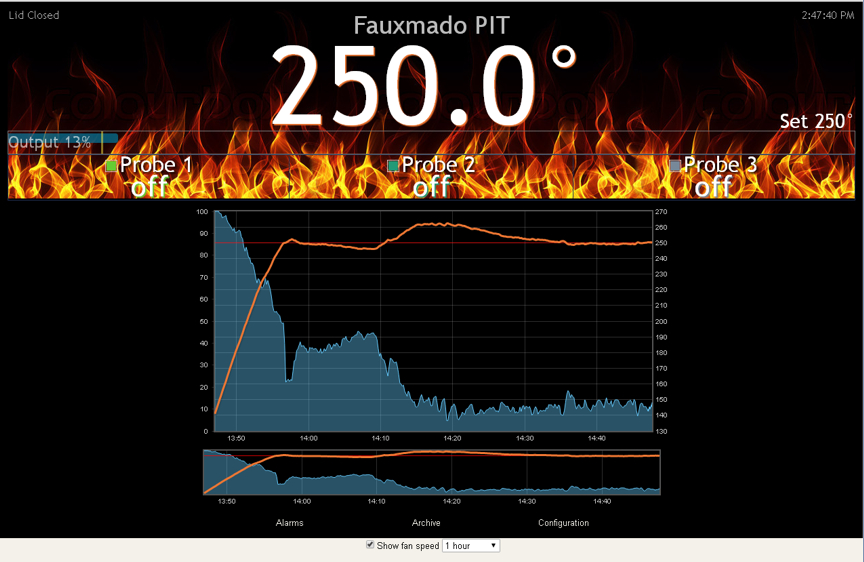

Here is a screen shot from the test run I just fired up:

For the above low and slow startup I put 1/2 a weber starter cube under a small pile of lump coal, just about enough to cover the bottom of the Akorn burn grate then pushed into a pile over the starter cube. I let it burn with the lid open until the white smoke from the starter cube was gone and I could see a small section of coals glowing at the bottom of the pile, then closed the lid with the top vent set so just the dimples were open. I set the vent tight like this because at this point the fan is blowing 100% and when the fan is blowing you want to keep the top vent open only a slight bit.

As you can see in the graph, while the HM is at 100% the temp rose rapidly, but as the temp approached the 250F setpoint these PID settings told the HM to back down the output which allowed the pit to settle nicely at 250F. When the temp settled at 250F the HM output was riding at roughly 50%, so the damper is sitting wide open and with the top vent just cracked to the dimples, the HM will eventually make the fan kick in to maintain the setpoint. I dont want this to happen because I want to use the damper only for this cook so I open the top vent to about 1 of 5 to allow convection air flow to get started. The first small bump in temp is right after I opened the top vent to 1, as you can see the pit held the setpoint nicely with the HM output just under 50%, this means I built the appropriate size fire to maintain the target temp with convection flow. I let it roll a while like that as an example, you can see the temp has a slight downward trend and the damper is nearly fully open (HM output near 50%), this shows the fire needs more air flow, but the top vent is close to where it needs to be at the 1 of 5 position. (which I already know from experience with this grill) For a real cook I would have opened the top vent to about 1.5 and put the food on the gill at the same time instead, after the lid mode timer expired the pit would have settled on the setpoint and the ballast of the cool food would helped keep the HM system stable.

Instead for this test cook I moved the top vent open to a 2 of 5 position just before you see the second bump in temp and the longer period of overshoot. This kinda shows the negative side of the convection flow control and PID settings that react sooner but in a less aggressive fashion. You can see even though the temp overshot about 10F the HM kept the output in the teens leaving the damper open about a third, which made the pit temp fall more slowly back down to the target, but it lands nicely right where you want to be with the damper opened about a third of the way and plenty of room to stoke or choke the fire.

On the other side of the coin, if I were using the blower to control the pit with the top vent only open a crack I could use faster and more aggressive PID settings which would close the damper right when the target temp is achieved. This would cause a more rapid temp bloom and higher overshoot temps that would fall quicker back to the target temp, at which point the fan would kick back in and land the pit on the target temp quicker. It is easier to control this kind of setup and it will generally hold the target temp a bit more accurately, say +/- 1F as opposed to +/- 3-5F with convection control, but the blower method will cause more air flow, more fuel consumption and leave smoke in the pit for a longer period of time.

So it comes down to priorities how you decide to run your pit, your experience with your grill and managing a pit may play a role in this decision. If you have solid technique and experience with the grill the damper only method might be good for you, if you just want easy control you are probably better off setting the blower and damper to run the full range with the top vent barely open.

Speaking of skills and technique, John brings up a good point about coal configuration re: minion method etc... This is something I did when I was less experienced with the HM on my Akorn, it did make things easier for me control by limiting the amount of coals that can be lit at once. I used what I call the "ring O fire" method, using a mesh ring I made in the middle and coals in a circle around the outside. This config will burn a really long time and the fire can never really get too big, another nice thing is you can place your wood chucks at strategic spots to control the smoke during the cook. Here is a pic of that configuration:

Hope this info was usefull and not too boring to read....