anthony.palumbo

TVWBB Member

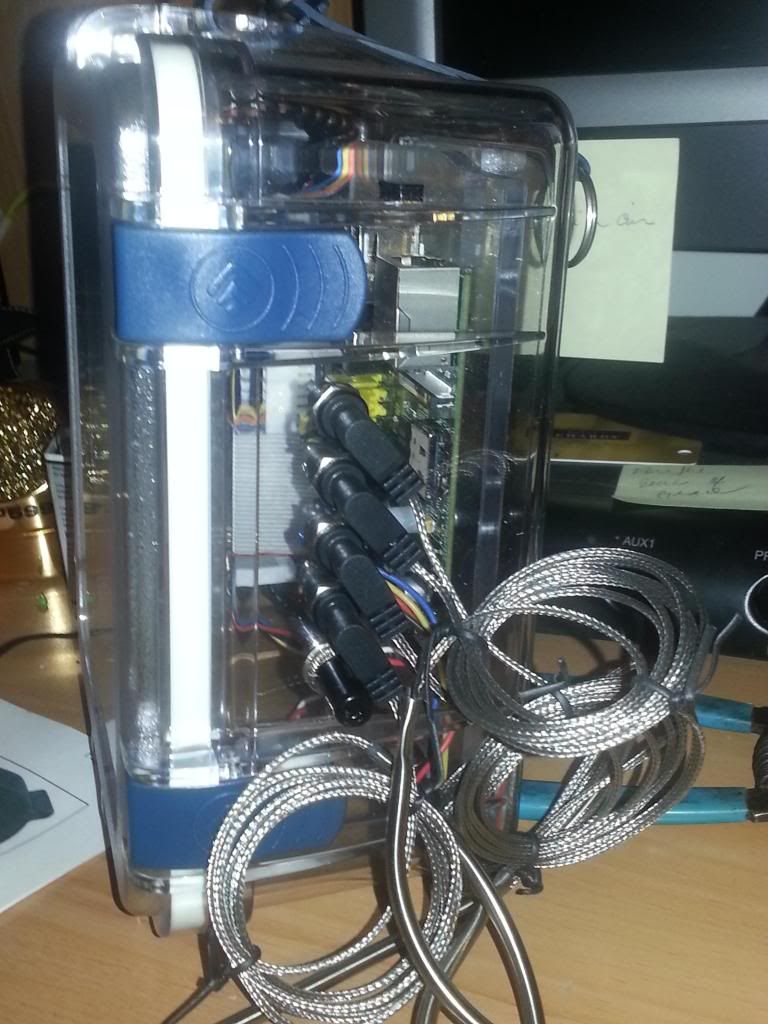

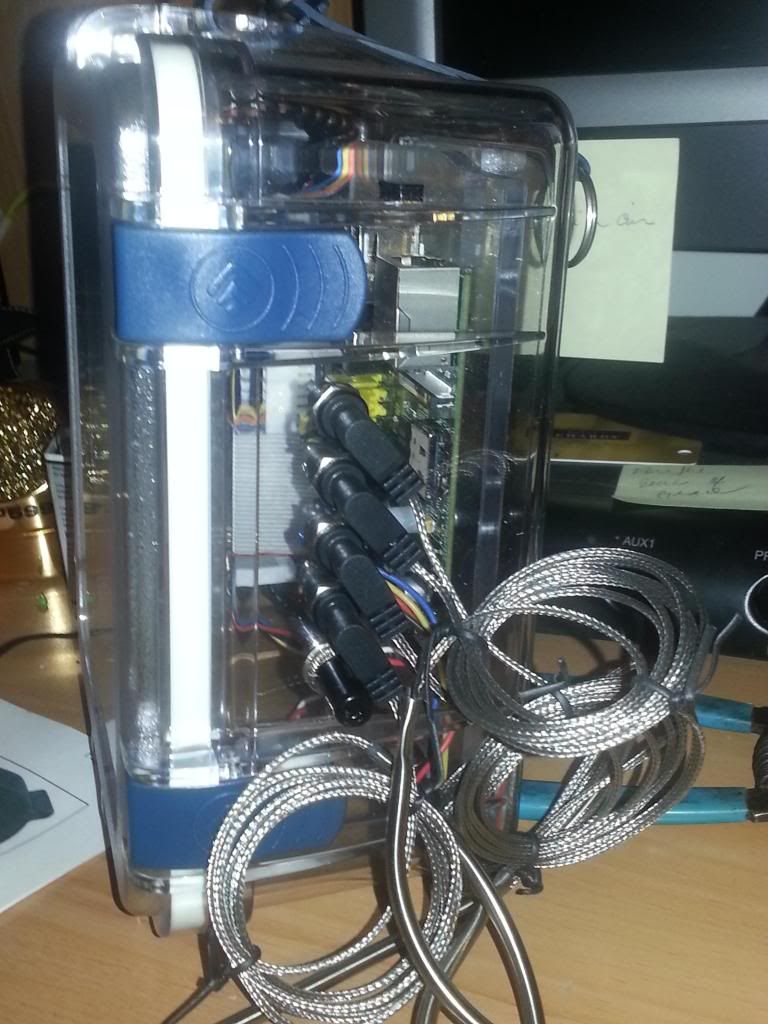

this is the dc power jack i am looking to get .....dc jack

I would like to get probe jacks that are similar and am thinking about using a 2.5 mm power jack for the blower.

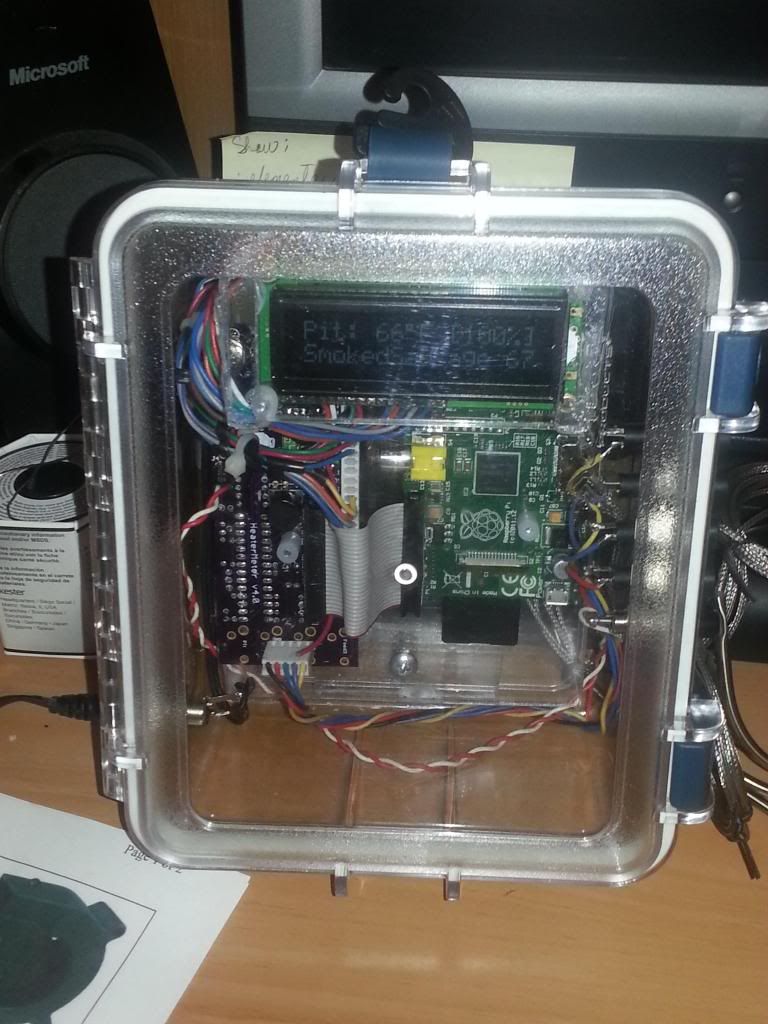

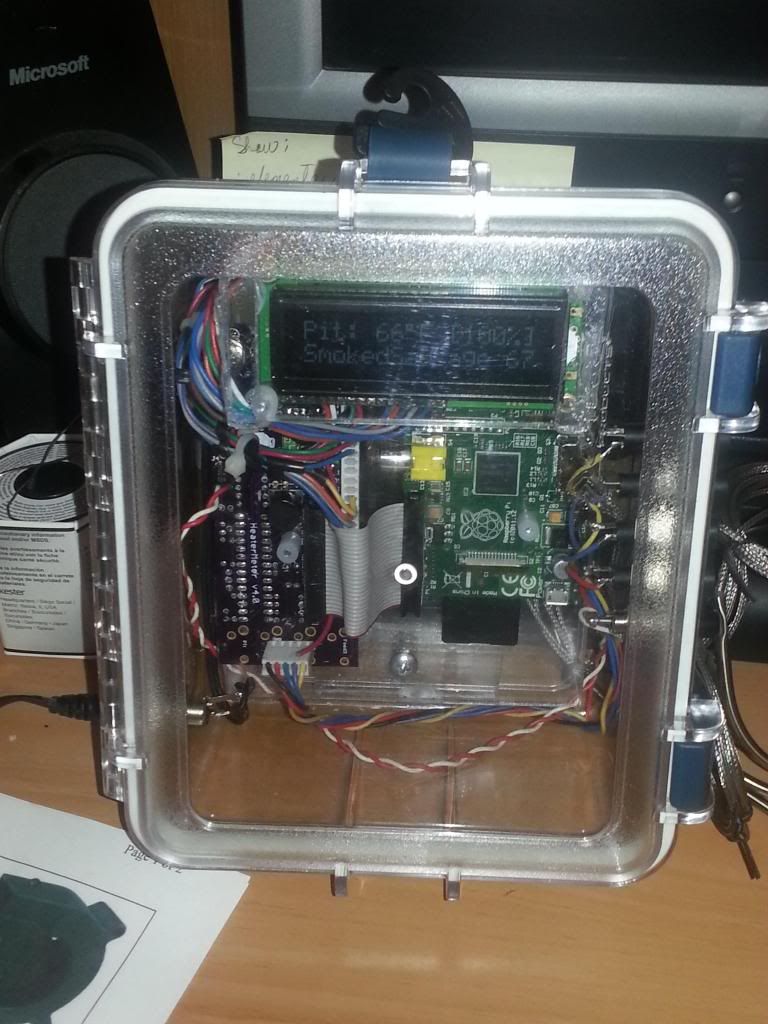

here is kinda what i am looking to do based on what another board member did

which can be found in this post

Any help would be great... i need parts that have the nut on them so that i can attach to the side like dale did. ...

I also was thinking about putting all connectors on the bottom and putting feet in the corner of the container so that the wires are on the bottom and when weather his it the water just runs off and nothing can get wet

I would like to get probe jacks that are similar and am thinking about using a 2.5 mm power jack for the blower.

here is kinda what i am looking to do based on what another board member did

which can be found in this post

Any help would be great... i need parts that have the nut on them so that i can attach to the side like dale did. ...

I also was thinking about putting all connectors on the bottom and putting feet in the corner of the container so that the wires are on the bottom and when weather his it the water just runs off and nothing can get wet