BrianBishop

TVWBB Member

First I'd like to thank everyone here for the inspiration to take on this project, I couldn't have done it without you!

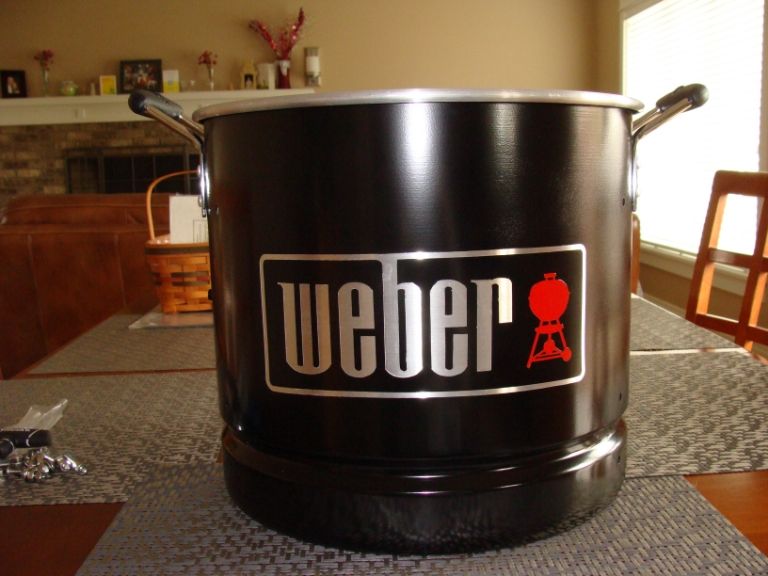

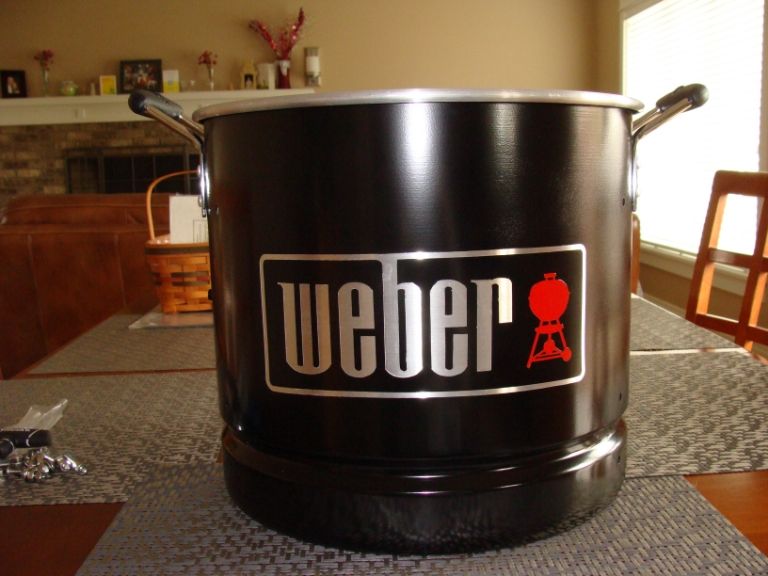

So here is my interpretation of the perfect Mini WSM...

Here's the inside. Bottom removed and all the holes drilled and lamp rod installed for probe passthrough.

All Painted and Stencil Pulled

Inside view with the racks installed. You may also notice the longer bolts ready to accept the tbd diffuser (I have a clay saucer but also like the idea of a pizza pan)

I bent the vent control handle from 1/4" ss rod I found at Ace Hardware and used my tap and die set to thread the ends 1/4-20

Another view of the vent control. Here you will notice I used the knob from the lid of the visconia pot as my handle.

I drilled out the original threaded insert, mortised in a 1/4-20 nut and epoxied it in place

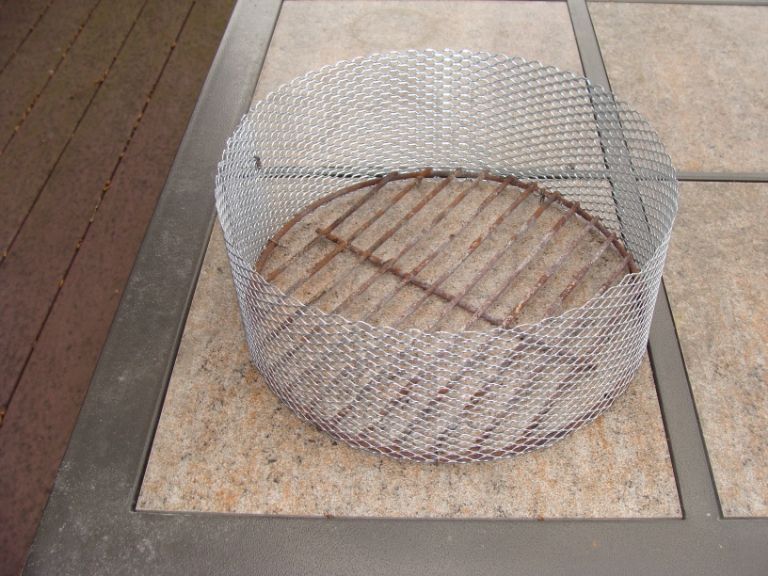

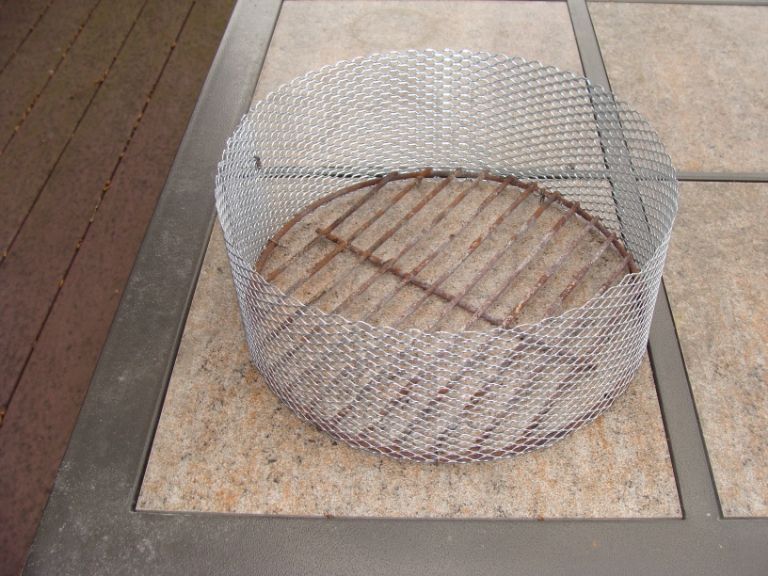

Here's the charcoal basket I built using gutter guard as I couldn't find expanded metal.

Here it is assembled and ready for action!

All assembled sitting next to BIG BROTHER

This was an incredibly fun project and I couldn't be happier with how it turned out! I can't wait to have my first cook on something I essentially built myself. Thanks again to everyone here for the guidance and a special shout out to Chad Bman for pushing me to go the extra mile on the paint job!

So here is my interpretation of the perfect Mini WSM...

Here's the inside. Bottom removed and all the holes drilled and lamp rod installed for probe passthrough.

All Painted and Stencil Pulled

Inside view with the racks installed. You may also notice the longer bolts ready to accept the tbd diffuser (I have a clay saucer but also like the idea of a pizza pan)

I bent the vent control handle from 1/4" ss rod I found at Ace Hardware and used my tap and die set to thread the ends 1/4-20

Another view of the vent control. Here you will notice I used the knob from the lid of the visconia pot as my handle.

I drilled out the original threaded insert, mortised in a 1/4-20 nut and epoxied it in place

Here's the charcoal basket I built using gutter guard as I couldn't find expanded metal.

Here it is assembled and ready for action!

All assembled sitting next to BIG BROTHER

This was an incredibly fun project and I couldn't be happier with how it turned out! I can't wait to have my first cook on something I essentially built myself. Thanks again to everyone here for the guidance and a special shout out to Chad Bman for pushing me to go the extra mile on the paint job!