Jim P.

TVWBB Fan

I recently aquired a new HeaterMeter and an Offset Rotary Valve. To make a long story short, due to some limitations on my end and to make sure everything actually worked, I contacted forum member Jas E to see If he could assemble a new HeaterMeter set-up for me. He could, he did, and I couldn't be happier. The whole process went perfectly from start to finish. Thanks again Jas.

Now that I had my new HM it was time to learn how to use it. Lots of reading of this forum, the GitHub Wiki, watching YouTube, and test of my new unit ensued. I haven't done that much homework in a long time. Well worth it though. One of the things I needed to accomplish was to get my blower attached to my WSM. After much searching around and not finding exactly what I wanted but getting some ideas, I tried to figure out something for myself. My requirements were that it had to be a simple design and it had to be easy to put together with a minimum of tools. Did I mention it had to be easy?

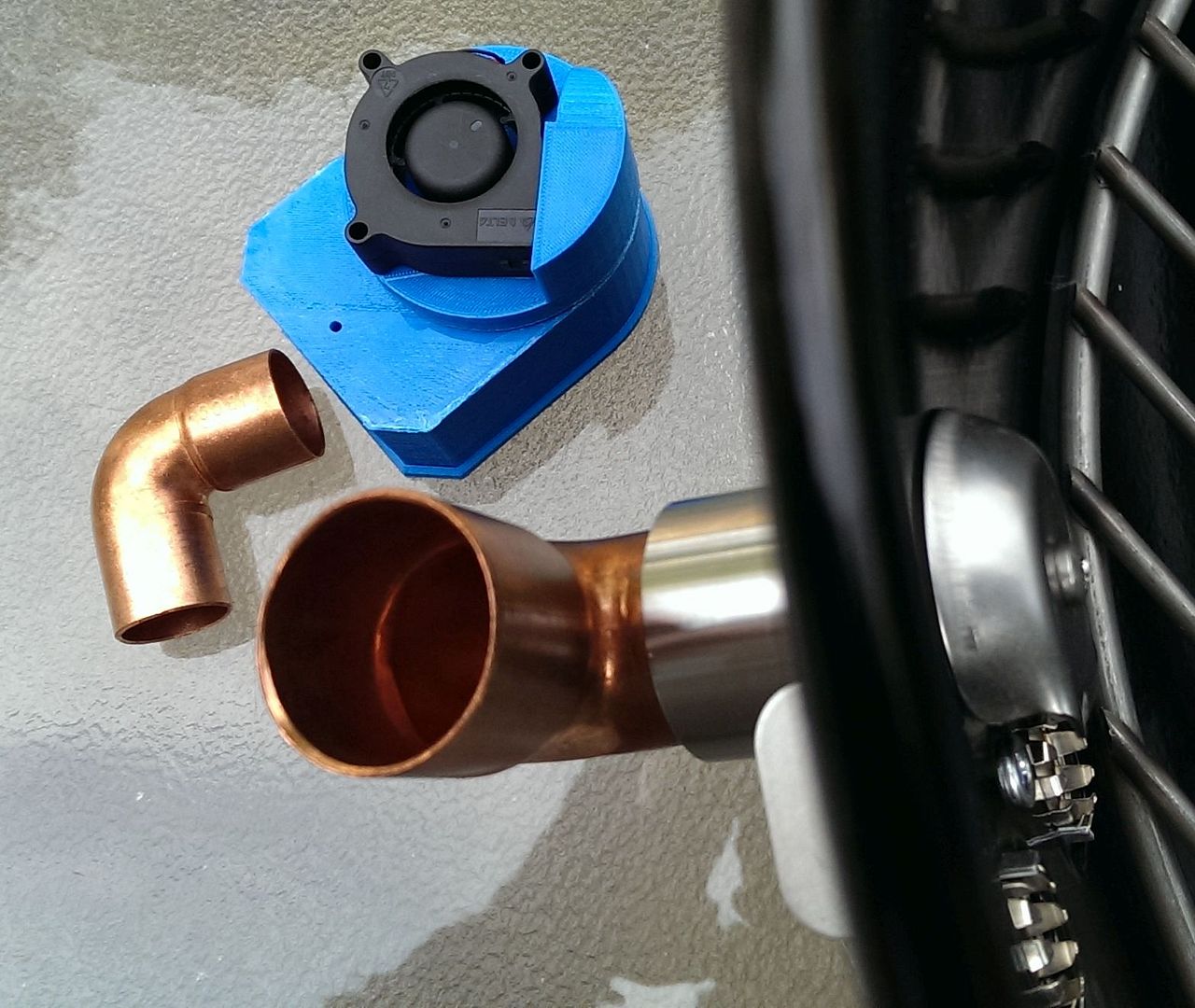

This is what I came up with.

I ended up using a universal weber adaptor from BBQ Guru. Not a perfect solution but I will see how it goes for several cooks. The most difficult part of the whole build was fitting the copper fitting into the stainless adaptor. The id of the adaptor is not a standard size, the 1" side of the copper fitting was too big and the 3/4" was too small. I bought some o-rings to try to make a tight fit. Unfortunately the o-ring would not stay in place when I was trying to press fit the pieces together. My inelegant solution was to score the copper fitting with a pipe cutter just enough to give the o-ring enough bite to not slide up the fitting. To my utter amazement it worked! It has even stayed in place as of this post. More experimentation might be in the future. The rest of the build is just two 90 degree, 1" to 3/4" copper adapters. Everything is just press fit together for easy disassembly. Not at all because I don't want to solder anything. There aren't any air leaks that I can detect. So far, so good.

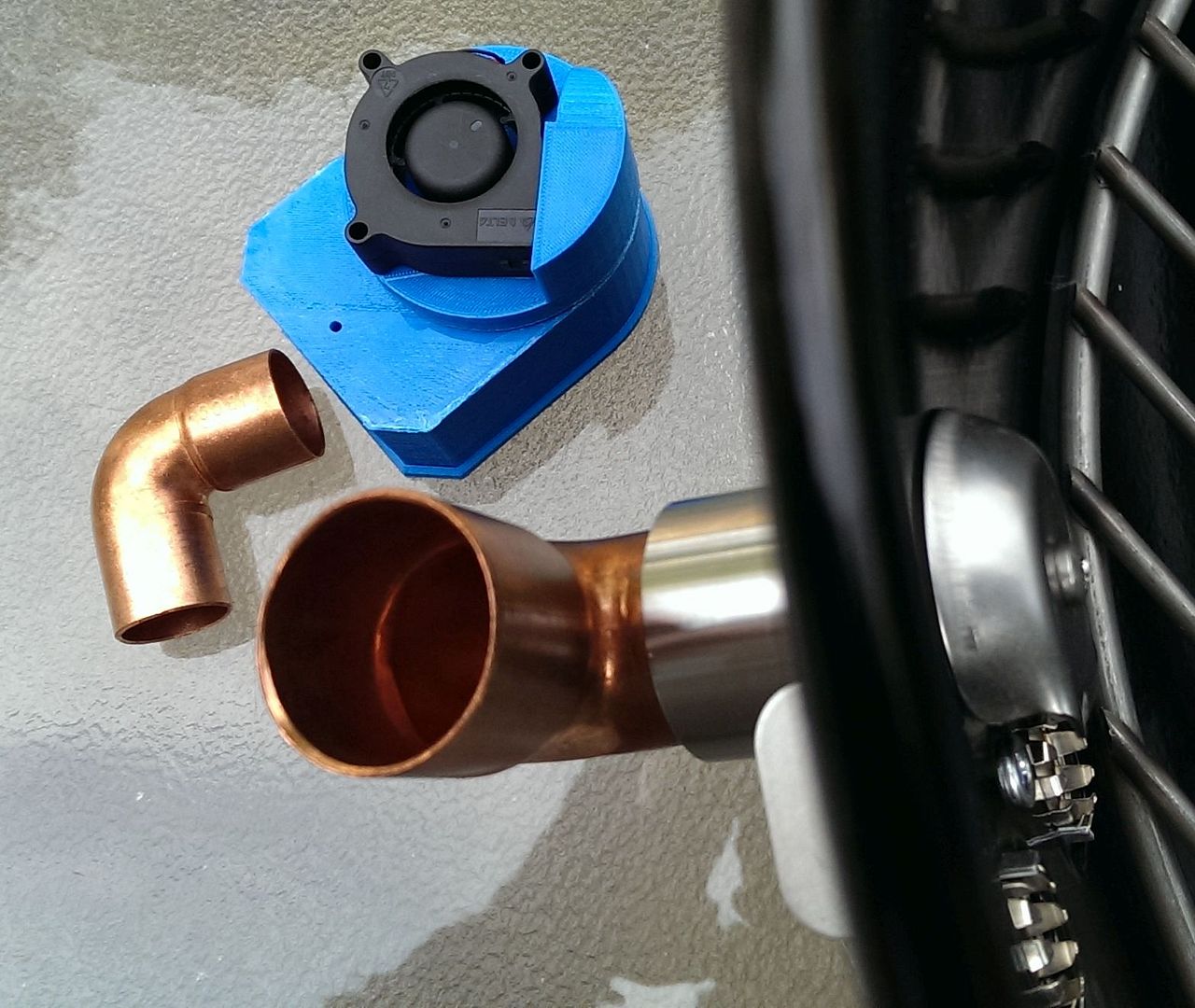

A couple of more pics.

If you look closely you can see the black o-ring in the adaptor.

Disassembled.

Onto make some great smoked food. I can't wait!

Jim

Now that I had my new HM it was time to learn how to use it. Lots of reading of this forum, the GitHub Wiki, watching YouTube, and test of my new unit ensued. I haven't done that much homework in a long time. Well worth it though. One of the things I needed to accomplish was to get my blower attached to my WSM. After much searching around and not finding exactly what I wanted but getting some ideas, I tried to figure out something for myself. My requirements were that it had to be a simple design and it had to be easy to put together with a minimum of tools. Did I mention it had to be easy?

This is what I came up with.

I ended up using a universal weber adaptor from BBQ Guru. Not a perfect solution but I will see how it goes for several cooks. The most difficult part of the whole build was fitting the copper fitting into the stainless adaptor. The id of the adaptor is not a standard size, the 1" side of the copper fitting was too big and the 3/4" was too small. I bought some o-rings to try to make a tight fit. Unfortunately the o-ring would not stay in place when I was trying to press fit the pieces together. My inelegant solution was to score the copper fitting with a pipe cutter just enough to give the o-ring enough bite to not slide up the fitting. To my utter amazement it worked! It has even stayed in place as of this post. More experimentation might be in the future. The rest of the build is just two 90 degree, 1" to 3/4" copper adapters. Everything is just press fit together for easy disassembly. Not at all because I don't want to solder anything. There aren't any air leaks that I can detect. So far, so good.

A couple of more pics.

If you look closely you can see the black o-ring in the adaptor.

Disassembled.

Onto make some great smoked food. I can't wait!

Jim