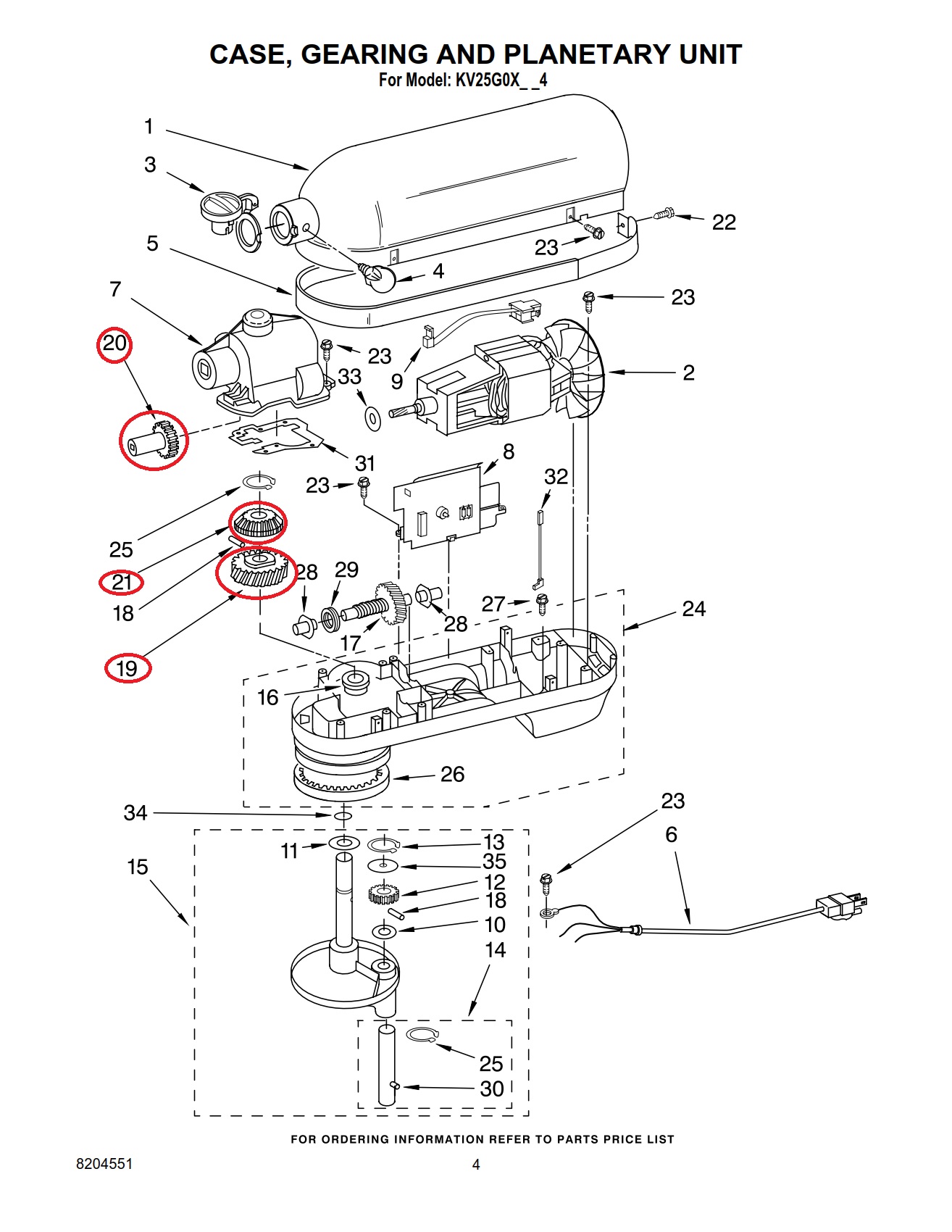

This is gear number 9706529, and you can see it has quite a bit of wear on it.

For what it's worth, this gear has carbon steel in it (a magnet stuck to it), but replacement gears look like they're made of bronze / brass? Are there any with carbon steel left for this part number, or has KitchenAid revised the material?

You can really see the concave gouge in this image...

This is gear number 9703337, and if you notice closely, you can see some wear on one side. I was going to ignore it, but it probably needs replacing?

One question about the worm gear bearing, are the concave washers identical, and does it matter if the bearing faces fore or aft?

This image shows the reverse side of the bearing...

The worm gear looks good to the best of my knowledge, although the sides of the teeth (large diameter gear) feel sharp like they need a bit of deburring.

Another shot of the worm gear...

Everything else looks good to me. I mic'd the planetary shaft, and there may have been .001 to .002 difference along the length of the shaft with the wear coming in the middle area of the shaft. I disassembled the whole head (removed the motor, cord, and control panel) so I can take it (lower part of the head assembly) to a local mechanic's parts washer tomorrow.

Not really the fuss I thought was going to be (I'd give the job a three-wrench rating), but I'll know more when I start to reassemble it all after I order the parts - wherever that may be from. I wonder if the local appliance repair stores carry such inventory?

Check this out...

https://www.searspartsdirect.com/part-number/9706529/0011/665.html

It's made out of brass, though, and it is an aftermarket part...