Hi,

I recently built a HM 4.2.4 with thermocouple and it works really well on my Primo L. Initially, I had started my journey into BBQ temperature control with a BBQ Guru CyberQ and I already had their 10cfm blower and adapter plate. The CyberQ works quite well, but one of the main limitations is the rather low maximum temperature of the pit probe, it's certainly not usable for high-temp cooks. On the HM I'm now using an Auber TC for the pit and the ChefAlarm probes for food. The HM is a great design, thanks a lot!

Since I still had to adjust the top vent and/or the manual damper built into the BBQ Guru blower, I decided to add a 3d-printed servo-controlled damper. In order to keep it away from the hot end of things, I made a very simple direct-drive design that controls the air intake side of the blower. The servo is a MG90S, the parts are PLA. Here a few photos of the setup:

The damper is quite tight, when fully closed and the fan is running at 100% there is no air flow out of the blower pipe. It also doesn't seem to unduly limit the airflow into the fan when fully open.

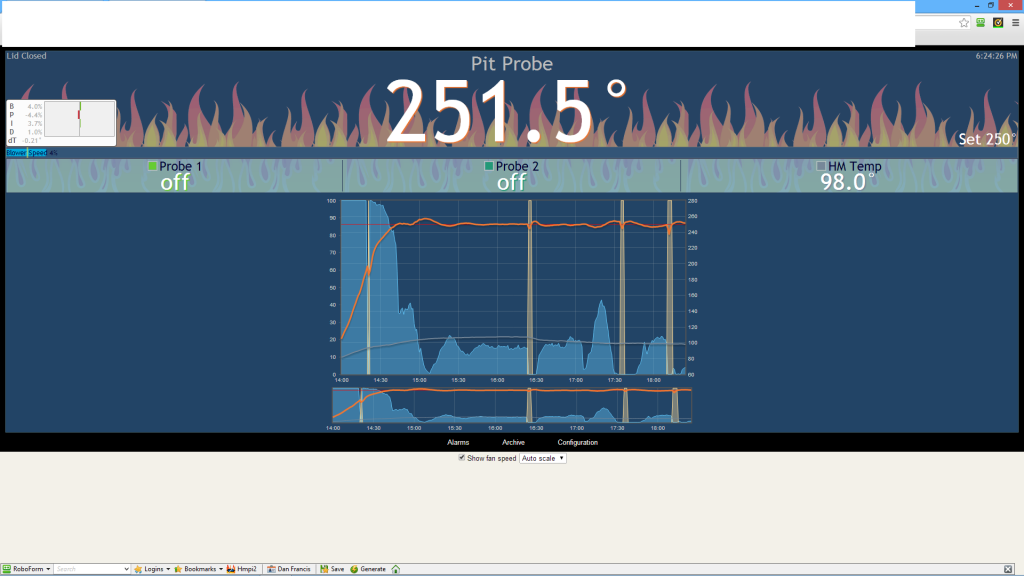

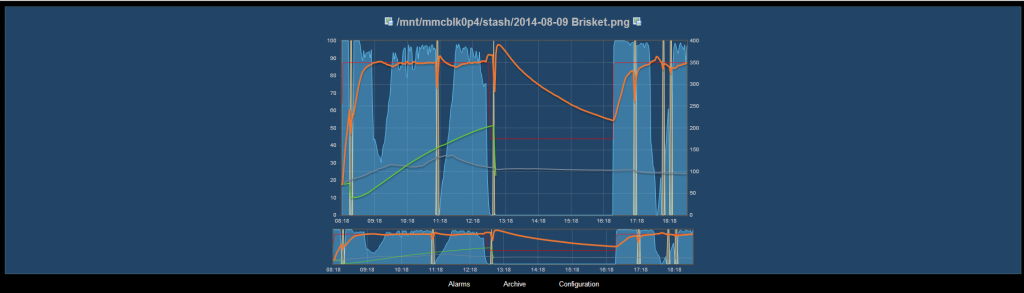

Last night I tried it out on the grill for the first time, using the damper in open/close mode:

The long flat top is an actual cook (whole chicken) and I opened the lid a few times, after that I started playing around, using the controller to try some high-temp settings just for fun. During the heat up to high temp I removed the center divider, added some charcoal and spread it out. I still didn't have enough charcoal in the grill to hold the temp at 700F, but keeping the temperature constant at 600F was no problem. At the end, the damper managed to shut down the fire (I closed the top vent some time later though).

If there is interest in the STL files for the damper, I'd be happy to post. It might also be interesting to combine the concept of intake air control with the standard blower.

Update: Here the link to the STL files: http://www.thingiverse.com/thing:431849

Steffen

I recently built a HM 4.2.4 with thermocouple and it works really well on my Primo L. Initially, I had started my journey into BBQ temperature control with a BBQ Guru CyberQ and I already had their 10cfm blower and adapter plate. The CyberQ works quite well, but one of the main limitations is the rather low maximum temperature of the pit probe, it's certainly not usable for high-temp cooks. On the HM I'm now using an Auber TC for the pit and the ChefAlarm probes for food. The HM is a great design, thanks a lot!

Since I still had to adjust the top vent and/or the manual damper built into the BBQ Guru blower, I decided to add a 3d-printed servo-controlled damper. In order to keep it away from the hot end of things, I made a very simple direct-drive design that controls the air intake side of the blower. The servo is a MG90S, the parts are PLA. Here a few photos of the setup:

The damper is quite tight, when fully closed and the fan is running at 100% there is no air flow out of the blower pipe. It also doesn't seem to unduly limit the airflow into the fan when fully open.

Last night I tried it out on the grill for the first time, using the damper in open/close mode:

The long flat top is an actual cook (whole chicken) and I opened the lid a few times, after that I started playing around, using the controller to try some high-temp settings just for fun. During the heat up to high temp I removed the center divider, added some charcoal and spread it out. I still didn't have enough charcoal in the grill to hold the temp at 700F, but keeping the temperature constant at 600F was no problem. At the end, the damper managed to shut down the fire (I closed the top vent some time later though).

If there is interest in the STL files for the damper, I'd be happy to post. It might also be interesting to combine the concept of intake air control with the standard blower.

Update: Here the link to the STL files: http://www.thingiverse.com/thing:431849

Steffen

Last edited: