Wow! This thing is so cool!

Last night I fab'd up scrap hunk of 1.25" tubing that was in the scrap pile with a small piece of 22g sheet metal and tacked it together with the TIG torch because my wife told me "had 5 minutes and she was starting dinner in the oven". We were having Salmon, brocolli, and mashed taters and I really wanted to cook the Salmon on the BGE with the HM even though I won't have the WiFi and new probes until later today.

So here is my 4 minutes of work (I was outside lighting it when I got the 5 minute warning):

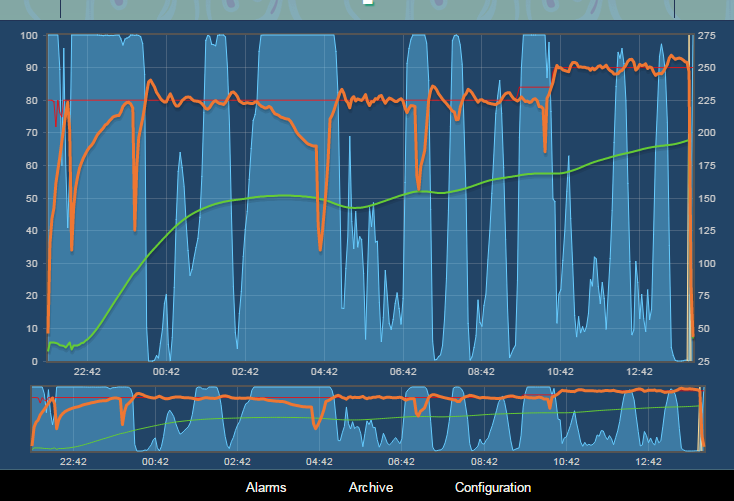

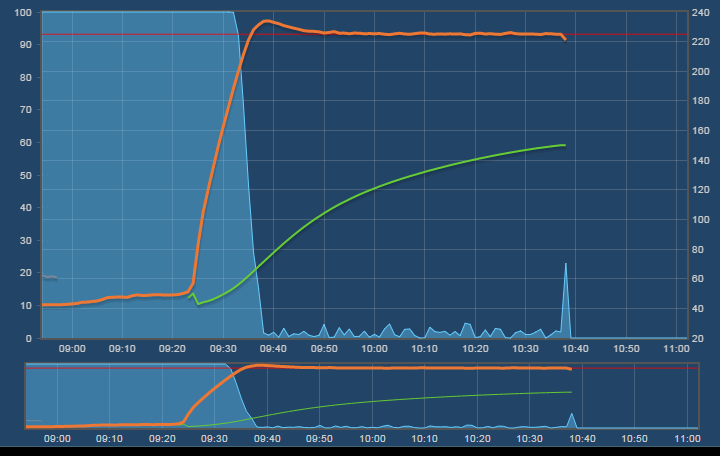

I as the temperature ramped up, I realized quickly that I needed to still control the top vent to be roughly what it would be to maintain 375 degrees as I overshot a bit. After getting that worked out, the temperature settled in at 375 and just sat there for the most part. I should have taken a picture of the hole on the other side of the sheet metal--I drilled a 3/16" pilot and then tacked the tubing on so that I could clamp the tubing in the vice and enlarge the hole with a stepper bit. I didn't measure, but opened it up to about 7/8" I'd guess thinking that I could make it bigger if need be--again, this is just a temporary solution and I'll make something nicer when I've got an hour.

The idea of the smaller hole was to build sort of a natural damper in that I wouldn't have a big enough opening to worry about free flow through the fan. I watched periodically and most of the time the fan was only running between say 20-40% and once I started to adjust the top vent a bit more, it dropped to between nothing and say 30%.

The next iteration will certainly have features to prevent the possibility of coals getting into the fan and look like a finished product rather than a thrown together w/ electrical tape thing.

Thanks again for all the help and I look forward to getting the WiFi working tonight.

Ralph, I've been reading about your rotodamper and depending on what I come up with, you may be seeing an email from me though I may just play around and see what I can fab up too--I have some plans in my head that may or may not pan out. I'll certainly keep you guys posted with my progress.

Last night I fab'd up scrap hunk of 1.25" tubing that was in the scrap pile with a small piece of 22g sheet metal and tacked it together with the TIG torch because my wife told me "had 5 minutes and she was starting dinner in the oven". We were having Salmon, brocolli, and mashed taters and I really wanted to cook the Salmon on the BGE with the HM even though I won't have the WiFi and new probes until later today.

So here is my 4 minutes of work (I was outside lighting it when I got the 5 minute warning):

I as the temperature ramped up, I realized quickly that I needed to still control the top vent to be roughly what it would be to maintain 375 degrees as I overshot a bit. After getting that worked out, the temperature settled in at 375 and just sat there for the most part. I should have taken a picture of the hole on the other side of the sheet metal--I drilled a 3/16" pilot and then tacked the tubing on so that I could clamp the tubing in the vice and enlarge the hole with a stepper bit. I didn't measure, but opened it up to about 7/8" I'd guess thinking that I could make it bigger if need be--again, this is just a temporary solution and I'll make something nicer when I've got an hour.

The idea of the smaller hole was to build sort of a natural damper in that I wouldn't have a big enough opening to worry about free flow through the fan. I watched periodically and most of the time the fan was only running between say 20-40% and once I started to adjust the top vent a bit more, it dropped to between nothing and say 30%.

The next iteration will certainly have features to prevent the possibility of coals getting into the fan and look like a finished product rather than a thrown together w/ electrical tape thing.

Thanks again for all the help and I look forward to getting the WiFi working tonight.

Ralph, I've been reading about your rotodamper and depending on what I come up with, you may be seeing an email from me though I may just play around and see what I can fab up too--I have some plans in my head that may or may not pan out. I'll certainly keep you guys posted with my progress.