Scott S (scooter)

TVWBB Member

Would appreciate some feedback on a few questions about the Stoker capabilities.

I just bought a Stoker with 5cfm fan with 4 food probes and 2 pit probes. It's on backorder for a couple weeks so I can change the order if needed.

I have an 18"WSM and a MAK pellet cooker. The Stoker will control the WSM and monitor the temps in the pellet cooker. Sometimes at the same time.

My setup:

95% of the time: 900' elevation - SF Bay Area, CA

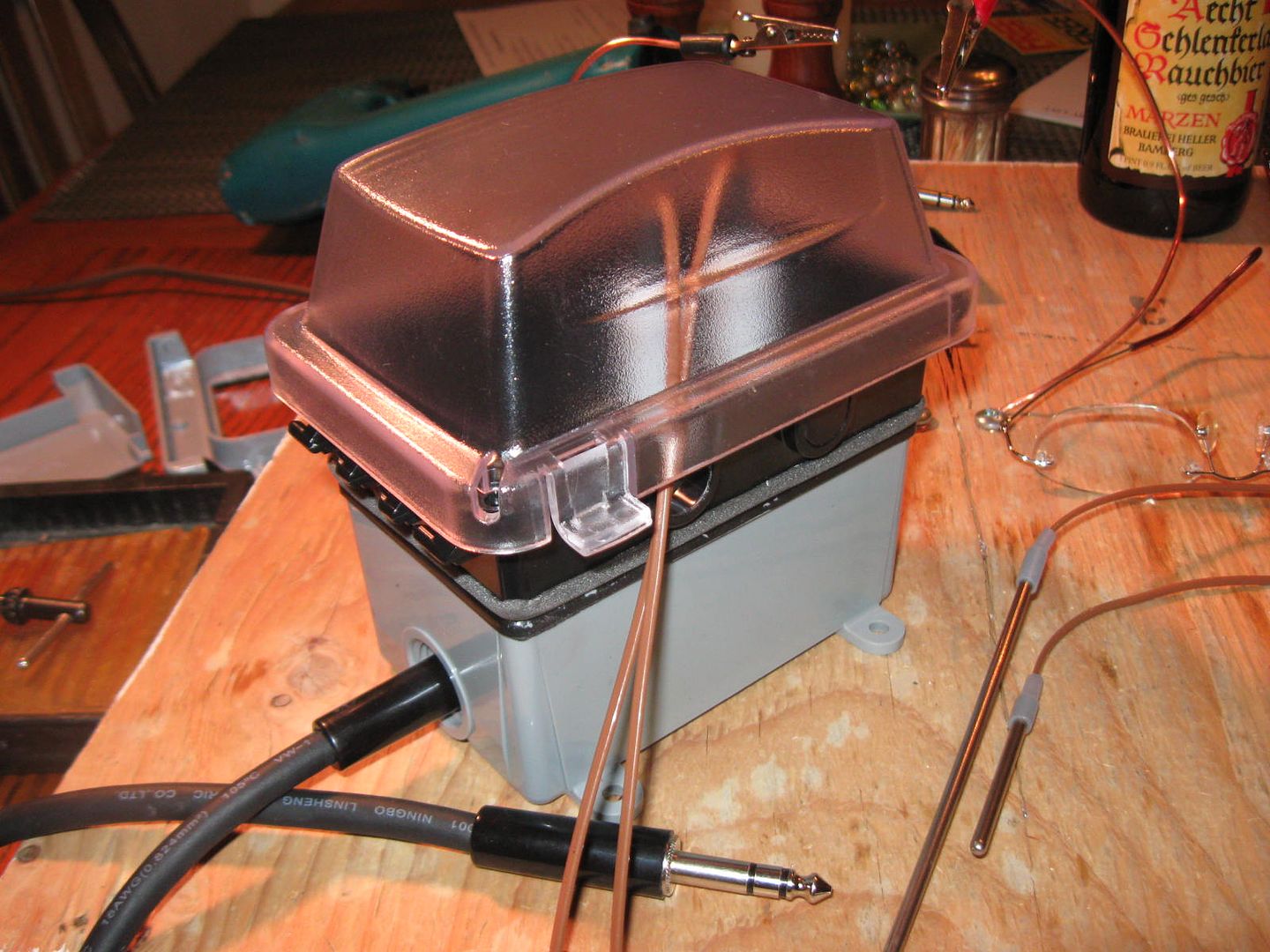

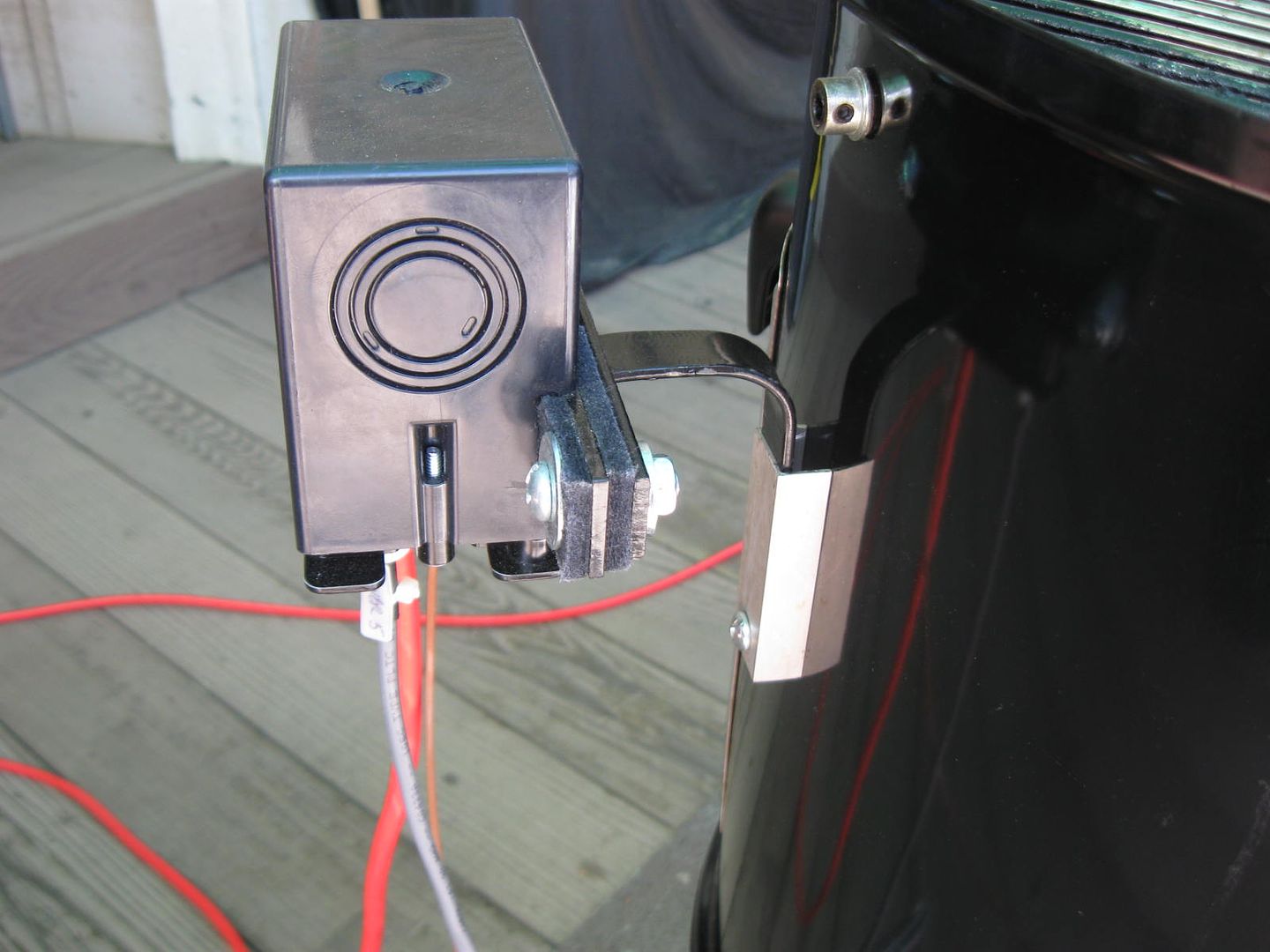

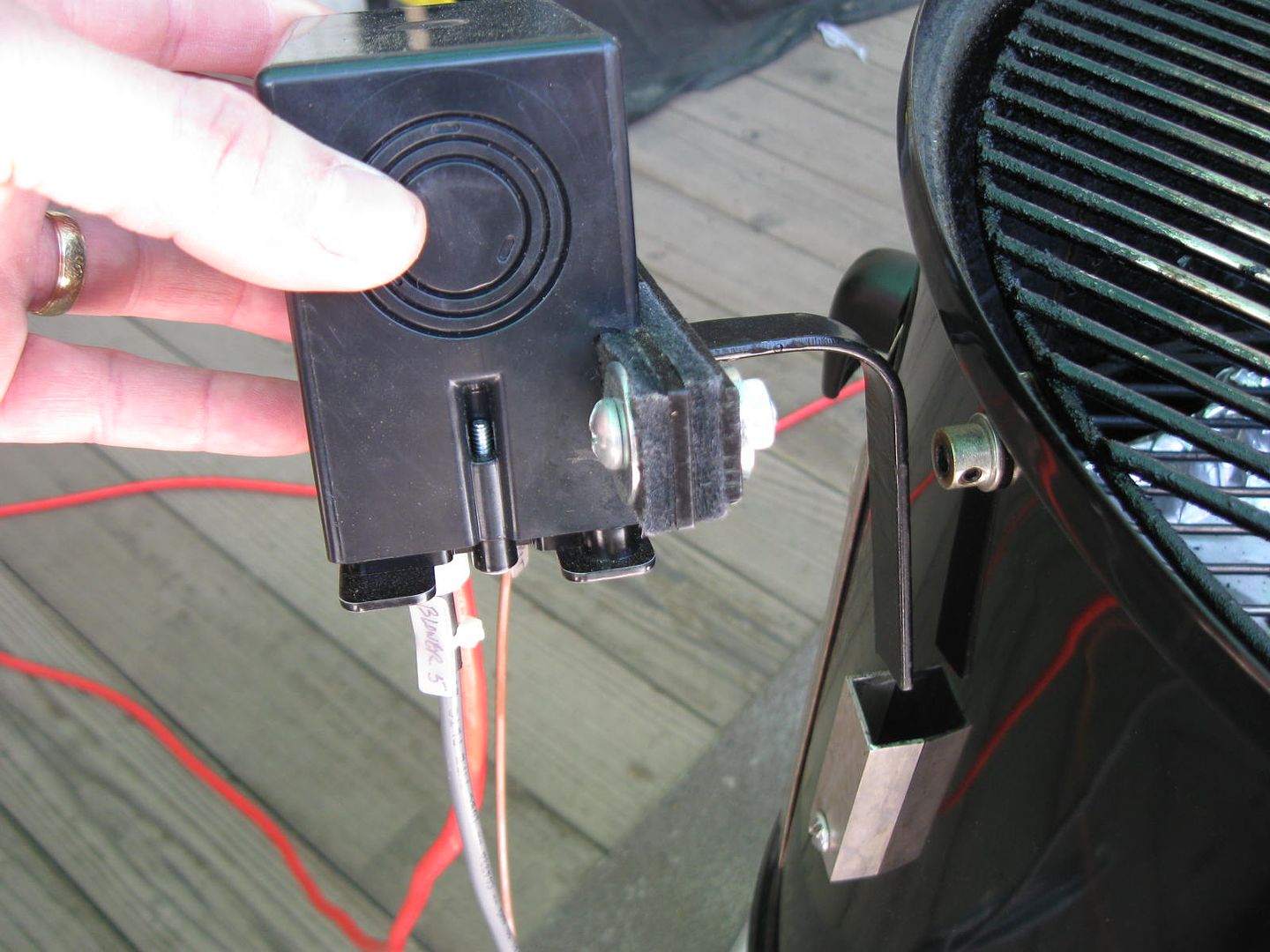

Stoker unit will be kept in the house protected from the elements wired into a LAN switch. I'll have a 40' 18AWG 3 conductor cord (male stereo 1/4" TRS plugs on both ends**) running from the Stoker under the house then out to the backyard where my WSM and MAK are located. One end connected to the stoker, the other end by the cookers will plug into a home made patch panel of 7 serial connected stereo 1/4" TRS jacks wired with 18AWG wiring.

Will use the Stoker to monitor and control the WSM, Will also use a pit and food probe to monitor the MAK temps. Sometimes at the same time.

5% of the time: 3000' elevation

On vacation I'll have the Stoker out by the cooker protected from the elements in a plastic container with wireless router and with blower and probes plugged directly into the Stoker or the patch panel with short extension cord to the Stoker.

Or, with the same setup at comps in northern CA.

Cooking style on the WSM regardless of home or vacation:

70% of the time I cook from 300-350F

29% of the time I cook from 250-300F

1% of the time I cook at 425F (but don't really "need" to, just like to)

-Should I upgrade to the 10cfm blower?

-The 40' 18AWG 3 conductor extension cord will handle the load with 10cfm blower?

-Do I need the high current power supply?

**Both ends will have male plugs so I can disconnect at the the patch panel end and take the patch panel with me on vacation or comps using a shorter extension cable.

Feedback is very much appreciated!!

I just bought a Stoker with 5cfm fan with 4 food probes and 2 pit probes. It's on backorder for a couple weeks so I can change the order if needed.

I have an 18"WSM and a MAK pellet cooker. The Stoker will control the WSM and monitor the temps in the pellet cooker. Sometimes at the same time.

My setup:

95% of the time: 900' elevation - SF Bay Area, CA

Stoker unit will be kept in the house protected from the elements wired into a LAN switch. I'll have a 40' 18AWG 3 conductor cord (male stereo 1/4" TRS plugs on both ends**) running from the Stoker under the house then out to the backyard where my WSM and MAK are located. One end connected to the stoker, the other end by the cookers will plug into a home made patch panel of 7 serial connected stereo 1/4" TRS jacks wired with 18AWG wiring.

Will use the Stoker to monitor and control the WSM, Will also use a pit and food probe to monitor the MAK temps. Sometimes at the same time.

5% of the time: 3000' elevation

On vacation I'll have the Stoker out by the cooker protected from the elements in a plastic container with wireless router and with blower and probes plugged directly into the Stoker or the patch panel with short extension cord to the Stoker.

Or, with the same setup at comps in northern CA.

Cooking style on the WSM regardless of home or vacation:

70% of the time I cook from 300-350F

29% of the time I cook from 250-300F

1% of the time I cook at 425F (but don't really "need" to, just like to)

-Should I upgrade to the 10cfm blower?

-The 40' 18AWG 3 conductor extension cord will handle the load with 10cfm blower?

-Do I need the high current power supply?

**Both ends will have male plugs so I can disconnect at the the patch panel end and take the patch panel with me on vacation or comps using a shorter extension cable.

Feedback is very much appreciated!!