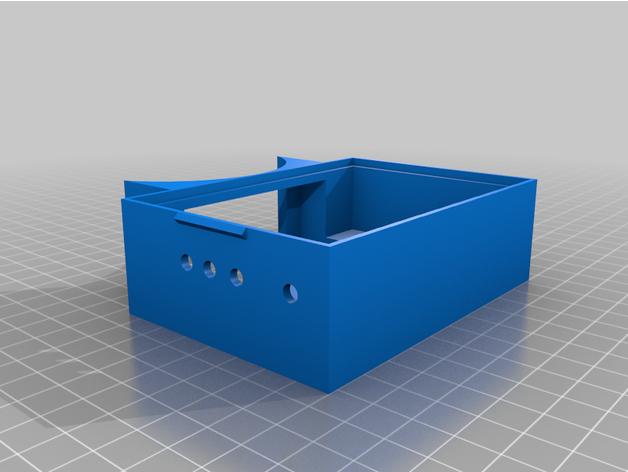

I attempting to make an all in one HM-adapt-a-damper design using a pi zero w. I would like to integrate the boards into the adapt-a-damper design but wanted to ask if anyone has done something similar or has any suggestions. I am a mechanical designer and have my own 3d printer so I am willing to prototype but why make a wheel three times when your friends can help you make it once!

I have ordered everything to make a headless HM and an adapt-a-damper (base board, pi zero, mgs90s servo and 5020 fan) and I am very excited to put this on my grill. I have been lurking the forms for the past few weeks and could find anything using the stock components.

best,

Andrew

I have ordered everything to make a headless HM and an adapt-a-damper (base board, pi zero, mgs90s servo and 5020 fan) and I am very excited to put this on my grill. I have been lurking the forms for the past few weeks and could find anything using the stock components.

best,

Andrew