You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printed Barrel Servo/Fan

- Thread starter Tom Kole

- Start date

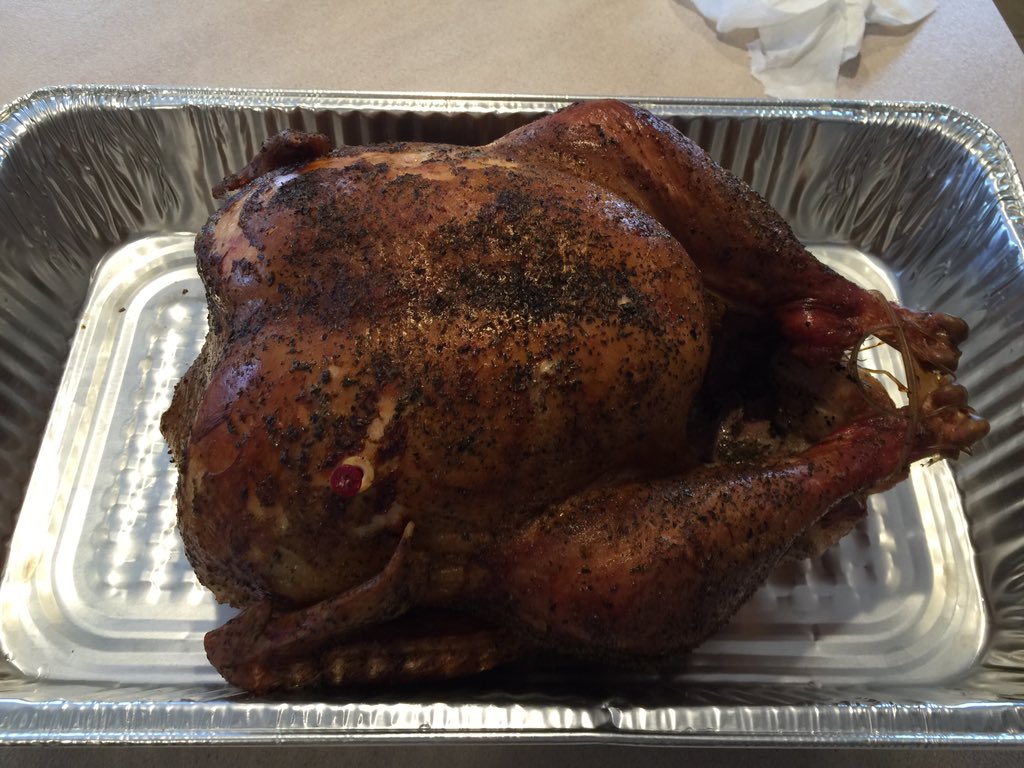

So the barrel blower design turned out awesome for this year's 2nd Turkey. Thanks for keeping this design open source and sharing with the community!

Did you actually print the connection to the Kamado? It loosk like that. Wont it melt?

@Tom

Which one of the two designs do you prefer? The offset or the inline version? I see that most of the people rather use your older design or the offset version. Anyone with experience on the inline version?

The big difference to me is, that for the offset version the servo has to work harder as it has the weight of the blower to turn as well. This is different at the inline version but does that actually work? Wouldnt this create like negative pressure? I know it isnt that airtight, but I am not sure if it makes sense to me to regulate the air intake before the blower, instead of regulating the airflow afterwards.

Which one of the two designs do you prefer? The offset or the inline version? I see that most of the people rather use your older design or the offset version. Anyone with experience on the inline version?

The big difference to me is, that for the offset version the servo has to work harder as it has the weight of the blower to turn as well. This is different at the inline version but does that actually work? Wouldnt this create like negative pressure? I know it isnt that airtight, but I am not sure if it makes sense to me to regulate the air intake before the blower, instead of regulating the airflow afterwards.

@Tom

Which one of the two designs do you prefer? The offset or the inline version? I see that most of the people rather use your older design or the offset version. Anyone with experience on the inline version?

The big difference to me is, that for the offset version the servo has to work harder as it has the weight of the blower to turn as well. This is different at the inline version but does that actually work? Wouldnt this create like negative pressure? I know it isnt that airtight, but I am not sure if it makes sense to me to regulate the air intake before the blower, instead of regulating the airflow afterwards.

Hey Alex, the offset is the main one I use. The reason I designed the other version was to attempt to make a completely enclosed system with very little mass for the servo to turn. The drawback is that there are more parts that need to be press fit together which are potential sources of leaks. That's why I like the offset so much and have never felt the need to redesign it. It has a completely closed path to the smoker and can be used at all operating temperatures for a kamado style grill. I'm working on a much bigger design for large pits that I'll hopefully be able to test in the next couple of months.

Tom

Hello Tom, I am even more confused now. I bought the "standard" 6cm blower and it doesnt fit. Took me a long time to get it to europe. But its the wrong one. Do you refer to the 5cm blower for the Barrel Servo?

The barrel damper was designed around the original 6cm blower. The offset and inline dampers use the 5cm blower.

The barrel damper was designed around the original 6cm blower. The offset and inline dampers use the 5cm blower.

After a bit of research it turned out that the chinese company obviously sold a counterfeited product with different measures. Again four weeks of waiting until I can assemble this piece of art. Darn.

HarryNagel

New member

Tom,

Which of your designs is best for a UDS Smoker?

Which of your designs is best for a UDS Smoker?

Jas E

TVWBB Super Fan

Tom,

Which of your designs is best for a UDS Smoker?

I've found the Offset Rotary Damper to be the most versatile design. It simply works well.

Not sure how it would work on a UDS, but I've been using Tom's barrel servo setup for a year now on my 18" WSM, and it's quite awesome. I'm sold on the "Fan before Damper" designs as of late after back to back tests with "RD3 type" setups. They just seem to be a bit more reliable regarding reproducible results. I haven't tried the Offset Rotary Damper(again, fan before damper), but from what I've read here on the forum. it works great.

Last edited:

Harry, it's hard to say which one works best. Jas is correct in that the offset one has the most versatility and can operate within the widest temp range. However, for bbq'ing have had a lot of graphs look like WBegg's for both of them. This stuff isn't rocket science. Almost any contraption will work. The HM does all the heavy lifting.

HarryNagel

New member

Thanks all!

Tom: It looks like three files RSD-UDS-cover.stl, RSD-UDS-top.stl, and RSD-valve.stl.

I am new to getting 3D prints, what plastic do most folks print in? I really only use the UDS to smoke at low temps 200-250, sometimes a little higher but it really hasn't been high since I cured the paint.

And from looking at them it looks like a spot for the jack has fins in it (I assume to support it during the printing process. Is that correct? And from reading it is the Home Depot Jack, correct?).

Thanks for your help!

Tom: It looks like three files RSD-UDS-cover.stl, RSD-UDS-top.stl, and RSD-valve.stl.

I am new to getting 3D prints, what plastic do most folks print in? I really only use the UDS to smoke at low temps 200-250, sometimes a little higher but it really hasn't been high since I cured the paint.

And from looking at them it looks like a spot for the jack has fins in it (I assume to support it during the printing process. Is that correct? And from reading it is the Home Depot Jack, correct?).

Thanks for your help!

HarryNagel

New member

Oh, and 100 or 200 mil?

HarryNagel

New member

I got a nice print from a local hub. I like the design and it works nicely. Thanks! I hope to try it out on the UDS this weekend.