You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

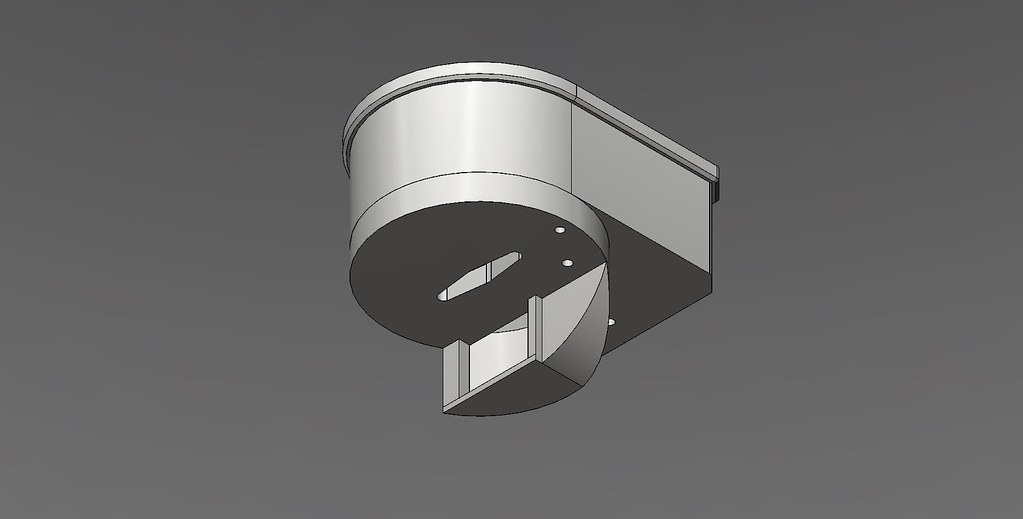

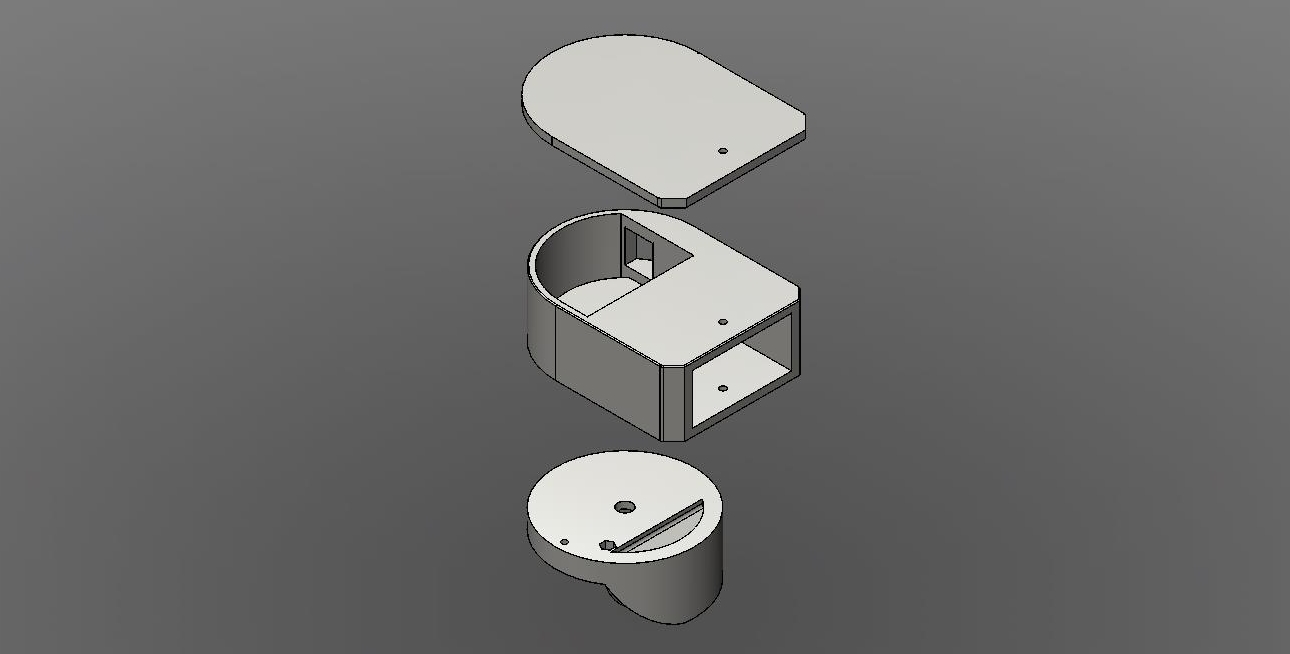

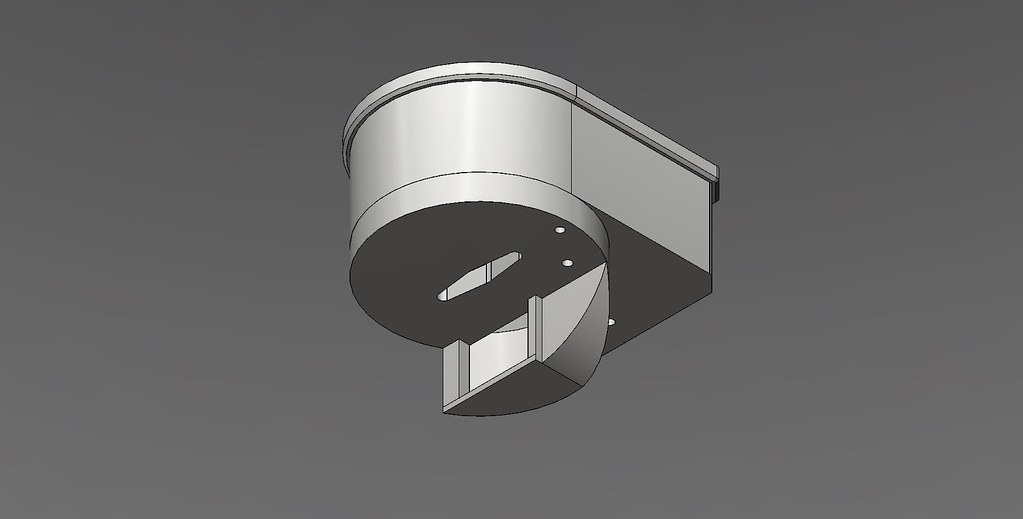

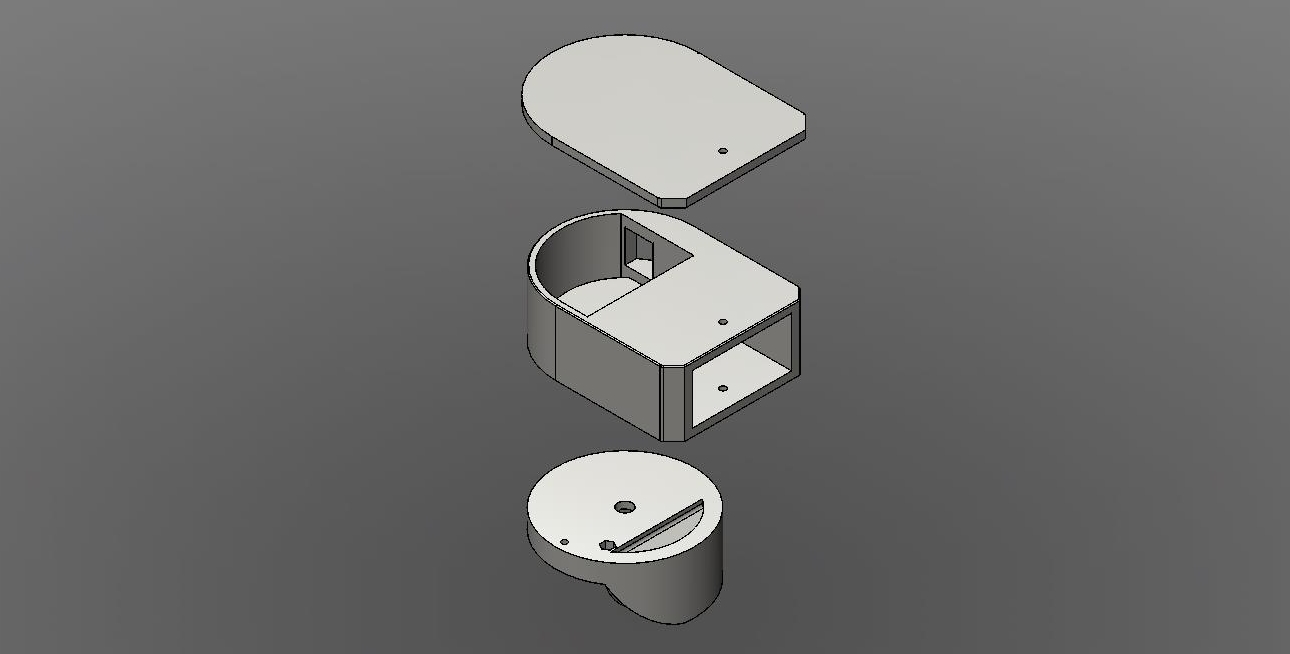

3D Printed Barrel Servo/Fan

- Thread starter Tom Kole

- Start date

Steve_M

TVWBB Guru

I'm sure this is a super-newbie question, but how are you guys using the blower and damper at the same time? I was under the impression that you could only use one or the other from the 4.0 PCB.

See here: https://github.com/CapnBry/HeaterMeter/wiki/Servo-Mode

Bryan Mayland

TVWBB Hall of Fame

You can use both from the v4.0 at the same time but you have to solder your own wire to the servo pin on the ATmega as shown in the wiki.

That's awesome! Thanks. One solution to those who don't like having a dongle connector is to do a panel mount enclosure and just add a 3-pin, RJ11 or RJ45.

You can use both from the v4.0 at the same time but you have to solder your own wire to the servo pin on the ATmega as shown in the wiki.

Wow, are you really able to slow smoke at 225 with an almost completely open top vent?So I started my experiment with using the servo/fan in fan mode with servo only on/off with the idea that I wanted to see what happened when I set it to behave like a computerized auber fan. My fan and PID settings are as follows:

Min fan: 10%

Max fan 40%

servo: on/off

B/P/I/D: 0/3/0.004/5

I am using a large BGE with the top vent as such:

The result surprised me at first, but now makes perfect sense. By setting the heatermeter this way, The fan only kicks in if the blower reaches > 10%, but the servo is full open at any value greater than 0. You can see that after the initial rise to temp, the fan has not kicked in at all and the servo has been able to hold the set point very tightly just by going on/off. The bonus is that if the system gets overwhelmed at some point and needs a little extra oxygen, it can call on the fan and still do so in a controlled manner without the fan coming on at 100%. I never thought about this before and think that it may turn out to be an interesting use of the heatermeter.

Wow, are you really able to slow smoke at 225 with an almost completely open top vent?

Yeah, but just the little holes. That vent can slide open even further for high temp cooking.

I'm impressed! I haven't used my Heatermeter as much as I would like but I was getting overshoot unless I had it only 1/8" or so open (not the big hole). I think it was drafting down from above. I'll have to try your PID values with it wide open after I get my Ralph valve.Yeah, but just the little holes. That vent can slide open even further for high temp cooking.

Btw, what lump are you using? I see that you have the stainless grate in the bottom as well.

Last edited:

Bryan Mayland

TVWBB Hall of Fame

Without the servo damper, I'd have to have my top "starfish" vent open so little that you couldn't even poke a toothpick through all the holes. With the servo damper I can open it all the way like Tom has it and it doesn't overshoot. It is surprising how much air can get drafted in through the blower hole, and how little drafts down from the top.

Btw, what lump are you using? I see that you have the stainless grate in the bottom as well.

I use the lump brand that home depot sells. I think it's called Cowboy but they may have recently switched. I recall the last time I bought it the packaging was different but I wasn't really paying attention. It's whatever lump is sitting next to the Kingsford bags.

I use the lump brand that home depot sells. I think it's called Cowboy but they may have recently switched. I recall the last time I bought it the packaging was different but I wasn't really paying attention. It's whatever lump is sitting next to the Kingsford bags.

Awesome, they have a few. They have Cowboy I believe an True Cue (which was clearanced).

Thanks for the comments Bryan! Great to have the developer on here commenting. I plan to try it again with the vents all the way after a redesign of the intake and an upgrade of my V 4.0 to have an Ethernet port (currently I just have a cat5 cable directly attached). What valve are you using these days?Without the servo damper, I'd have to have my top "starfish" vent open so little that you couldn't even poke a toothpick through all the holes. With the servo damper I can open it all the way like Tom has it and it doesn't overshoot. It is surprising how much air can get drafted in through the blower hole, and how little drafts down from the top.

Bryan Mayland

TVWBB Hall of Fame

I'm still using this duct thing. It has a few problems, the most notable that it mounts directly to a metal plate that slides into the Egg's vent door. When you heat the grill up around 500-600F, the heat starts creeping back into the plastic and softening it. It will begin to sag under the weight of the contraption in just one steak's worth of cooking. The sagging starts to warp the exit tunnel and makes a bad seal.What valve are you using these days?

Rather than try insulation I'm switching to something based on Ralph's rotodamper design because all you need is a an inch or two of distance away from the door to where temps have dropped significantly and the plastic is safe.

MikeNugent

New member

Tom, I just finished putting v2 of one of these together. My friend reprap'd it for me out of PLA. The finished product looks very nice. I had a couple small issues with fitment, but these could be due to the printing process itself. I had to do quite a bit of sanding, especially around the barrel area, to get things fitting and moving nicely. Did you lubricate yours at all? Mine seems to move pretty well, but I'd like to ease any strain on the servo that I can.

I am smoking a brisket on my WSM this weekend for my daughter's birthday. Planning to *gasp* leave the house for several hours right after I start the smoke. I would never do this without the heatermeter. I have mine set up for on/off servo mode, just to extend the life of the servo. I'll report back with results. Thanks again for your hard work, and for sharing your design.

I am smoking a brisket on my WSM this weekend for my daughter's birthday. Planning to *gasp* leave the house for several hours right after I start the smoke. I would never do this without the heatermeter. I have mine set up for on/off servo mode, just to extend the life of the servo. I'll report back with results. Thanks again for your hard work, and for sharing your design.

I just found this thread. This thing looks great. Just finished my HM build yesterday and am amazed at the work that has gone into HM so far. So a huge thank you to Bryan for HM, Tom for printing me a case and everyone else for contributing designs and ideas. Today I am looking into mounting options and just came across this. How are these working out for people. Tom have you decided whether you can print these for sale?

Sorry, I should have updated this thread. The barrel servo works well and I have used it on many cooks, but I think the rotary valve design that Ralph started probably works even better and is much easier to print and assemble. I have been using this design now for a while and have also made an in-line fan design that also works very well. I don't have a lot of time to print dampers in addition to cases so I've only printed a few for people. I will update the front page of this thread to reflect my recent observations and will point you to Ralph's thread for his original design.

I don't really use the barrel anymore. I mostly use the offset or in-line rotary designs. If I had to choose one, I'd probably go with the offset because there are less barriers to airflow given the dedicated air duct (See below). I just realized that I need to upload the most recent files for the offset and in-line dampers. I will do that tonight.

Offset rotary valve

Offset rotary valve