I thought it might be a good idea to start a thread for the different fan/cooker setups people have been using with temperature ranges that have been attained. I have a large BGE and am using the auber 6.5 cfm fan.

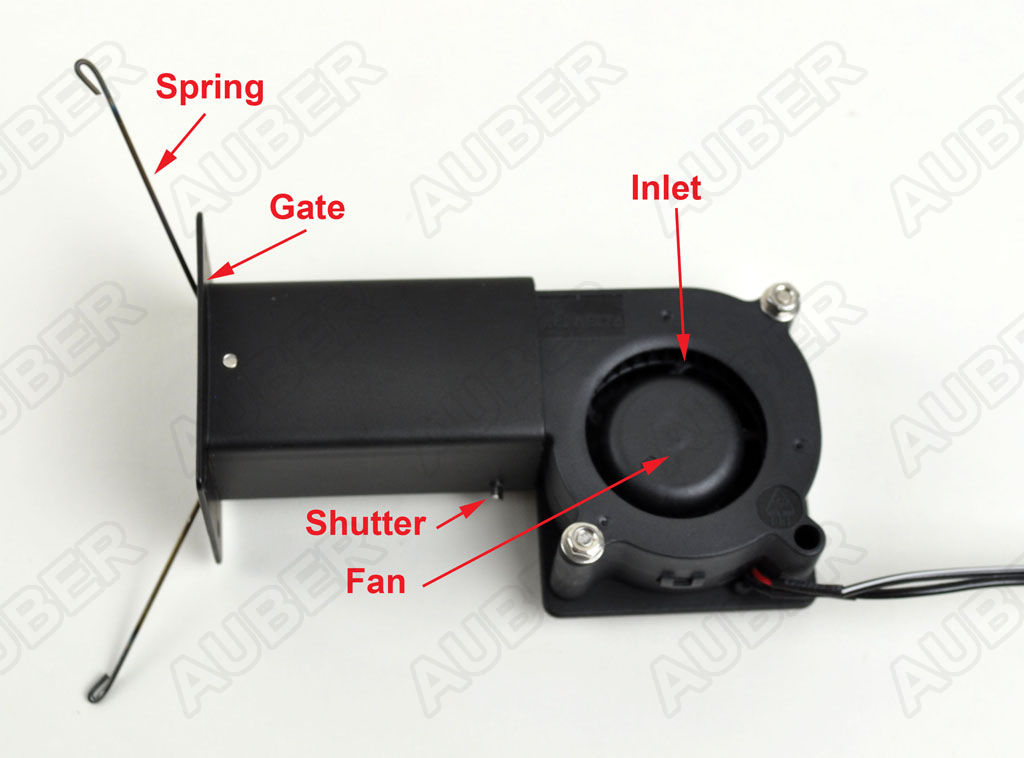

Specifications:

Power source 12 VDC, 3W

Cable length 4.5 ft (1.5 M)

Electric power connector 5.5 mm OD, 2.5 mm ID

Blower maximum flow rating 6.5 CFM*

Blower opening 0.8x1.0" (20x27 mm)

Maximum venting hole size for snap-on mounting 1.2" (32 mm)

Flange outer dimension 1.6 x2.0" (40x 50 mm)

Flange mounting hole distance 25 x 41 mm

Flange mounting hole size 3mm in diameter

Silicone foam gasket 4.5 mm (0.18") thick. Same outer and inner dimension as the flange

I have used it successfully for a couple 12-15 hr cooks at 225F with temp variations at steady state +/- 0.8F. I plan on doing some whole birds at higher temp soon and will post my results for control.

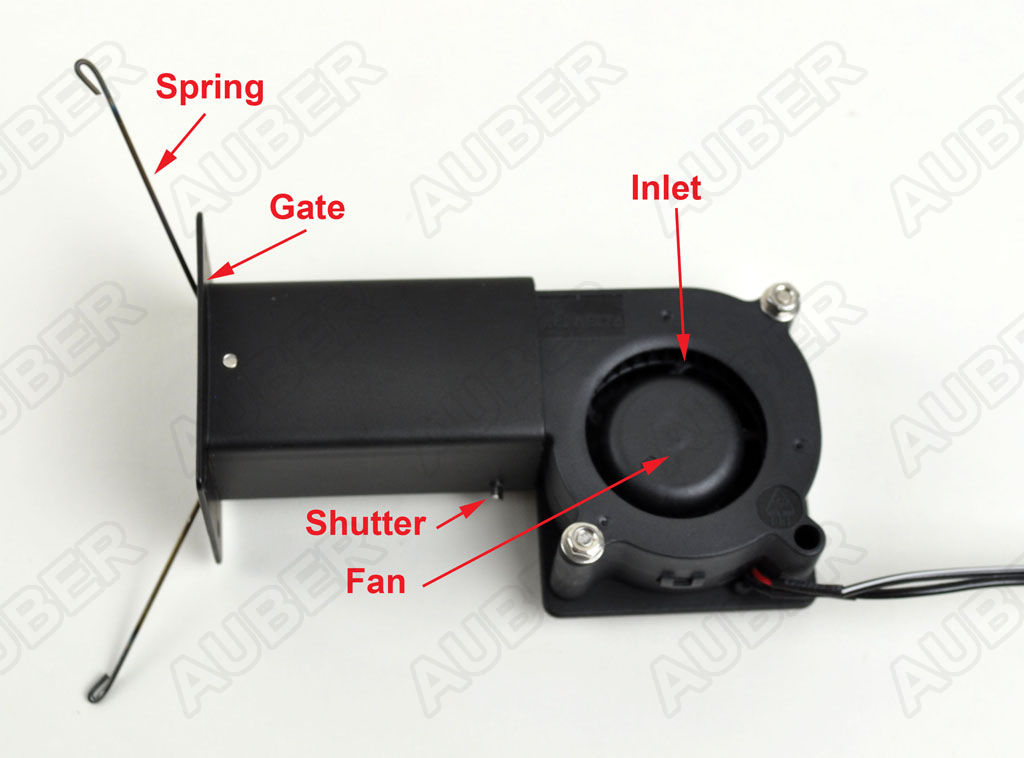

Specifications:

Power source 12 VDC, 3W

Cable length 4.5 ft (1.5 M)

Electric power connector 5.5 mm OD, 2.5 mm ID

Blower maximum flow rating 6.5 CFM*

Blower opening 0.8x1.0" (20x27 mm)

Maximum venting hole size for snap-on mounting 1.2" (32 mm)

Flange outer dimension 1.6 x2.0" (40x 50 mm)

Flange mounting hole distance 25 x 41 mm

Flange mounting hole size 3mm in diameter

Silicone foam gasket 4.5 mm (0.18") thick. Same outer and inner dimension as the flange

I have used it successfully for a couple 12-15 hr cooks at 225F with temp variations at steady state +/- 0.8F. I plan on doing some whole birds at higher temp soon and will post my results for control.