Guys, thanks again to all of you that have worked on the HM project and I wanted to share a little about what I've been working on too.

I've got zero talent when it comes to electrical/software stuff like you guys have but I certainly an capable in other disciplines. This is the BGE stand I built from 316 stainless and cedar as an example:

Since I first got my HM, I knew I wanted to build my own servo controlled damper but didn't really have the time to get busy with it until recently. The thing that I wanted to do was make the BGE breathe more naturally with a damper only instead of relying on the fan. That coupled with my library recently attaining a 3-D printer has let me do a quick proof of concept of my design and I did a test cook this weekend on a pork butt.

I've been using one of Tom's designs for the past year and it's worked really well for me but it did require that the fan kick in every now and then especially toward the end of the cook. I don't know what the surface area allows for for flow rate but it's clearly under one square inch. The damper I'm working on is just over two square inches and doesn't have anything (including a fan) blocking the air path. I was also hopeful that it would work better for cooks in the range of 375-425 and so far it seems to be ok for that as well after a quick test cook on Friday night. I'm not going to post pictures of the prototype but will certainly follow up this thread with the real thing as I get it done. Hopefully I can work on it some this week so they won't be too far away.

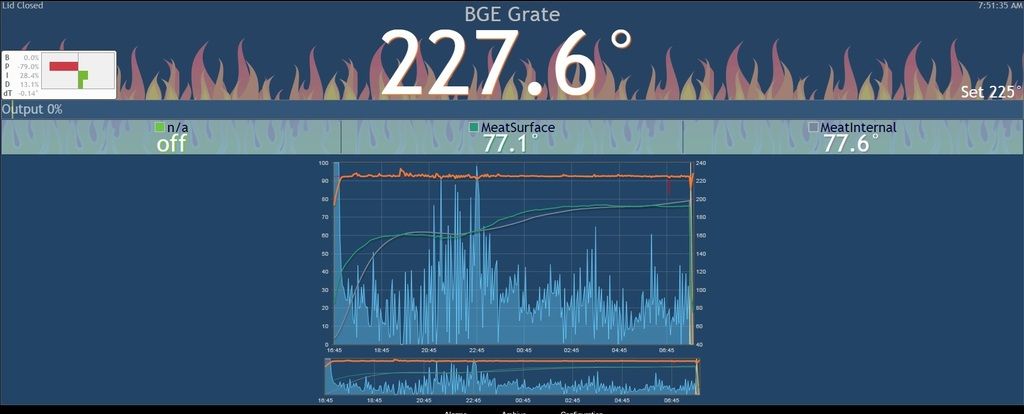

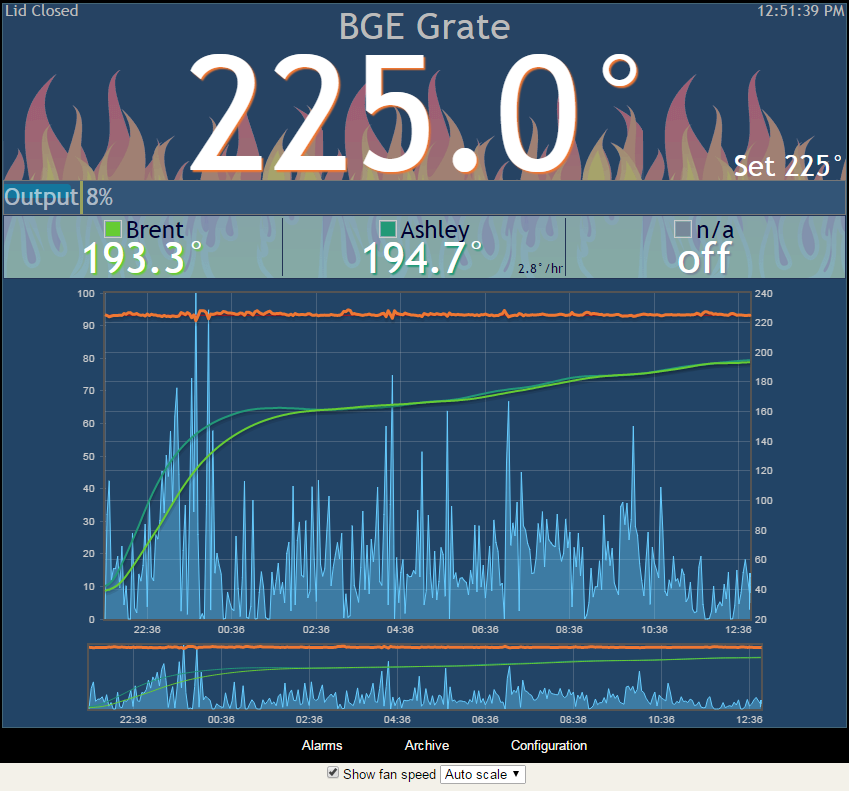

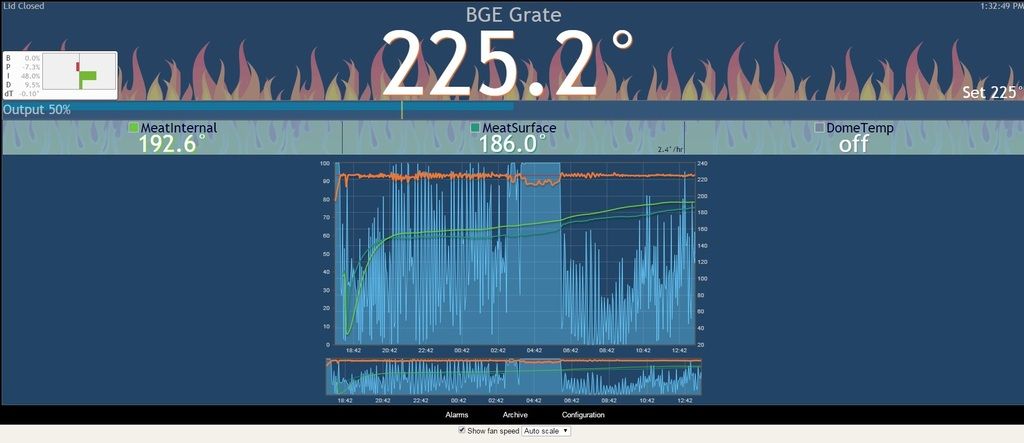

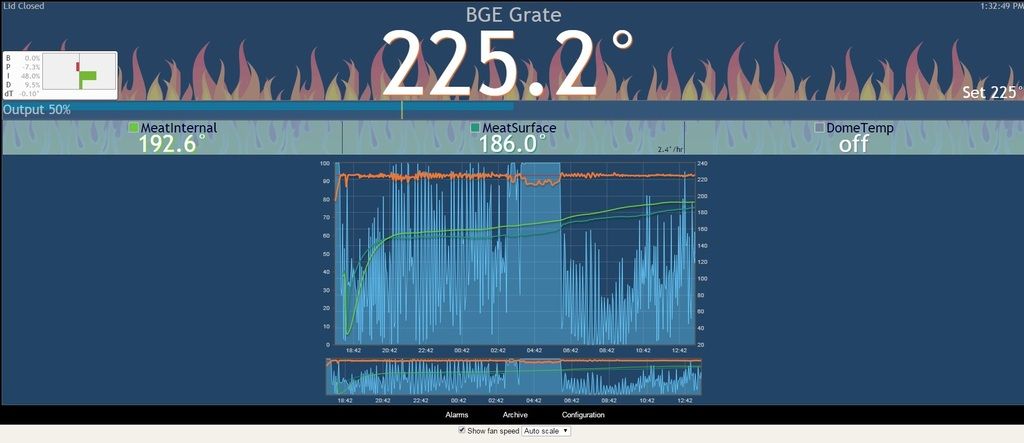

What I do have is the first cook temperature profile here:

It took me forever to get the PID settings as they are wildly different than anything I've seen posted so far and from Tom's design. I finally gave up last night after having no success and went to bed hoping it would settle out and never really did until I recalculated this morning (thanks to Excel using the TLC tuning rules) and finally got something that's looked good since mid morning:

P=30

I=.0227

D=95

It's still not quite dialed in but it's working a lot better than it had been working for sure. I'll keep monkeying with it but for me this is enough to go from the POC to construction of the final design. I'll certainly post details up as this project progresses.

As far as "whomper damper", I sail and other sailors may remember the movie "Wind" from the early 90s and the big sail that won the race was named the Whomper. Having this thing breathe through such a large cross section reminded me of that movie so whomper damper it is.

I've got zero talent when it comes to electrical/software stuff like you guys have but I certainly an capable in other disciplines. This is the BGE stand I built from 316 stainless and cedar as an example:

Since I first got my HM, I knew I wanted to build my own servo controlled damper but didn't really have the time to get busy with it until recently. The thing that I wanted to do was make the BGE breathe more naturally with a damper only instead of relying on the fan. That coupled with my library recently attaining a 3-D printer has let me do a quick proof of concept of my design and I did a test cook this weekend on a pork butt.

I've been using one of Tom's designs for the past year and it's worked really well for me but it did require that the fan kick in every now and then especially toward the end of the cook. I don't know what the surface area allows for for flow rate but it's clearly under one square inch. The damper I'm working on is just over two square inches and doesn't have anything (including a fan) blocking the air path. I was also hopeful that it would work better for cooks in the range of 375-425 and so far it seems to be ok for that as well after a quick test cook on Friday night. I'm not going to post pictures of the prototype but will certainly follow up this thread with the real thing as I get it done. Hopefully I can work on it some this week so they won't be too far away.

What I do have is the first cook temperature profile here:

It took me forever to get the PID settings as they are wildly different than anything I've seen posted so far and from Tom's design. I finally gave up last night after having no success and went to bed hoping it would settle out and never really did until I recalculated this morning (thanks to Excel using the TLC tuning rules) and finally got something that's looked good since mid morning:

P=30

I=.0227

D=95

It's still not quite dialed in but it's working a lot better than it had been working for sure. I'll keep monkeying with it but for me this is enough to go from the POC to construction of the final design. I'll certainly post details up as this project progresses.

As far as "whomper damper", I sail and other sailors may remember the movie "Wind" from the early 90s and the big sail that won the race was named the Whomper. Having this thing breathe through such a large cross section reminded me of that movie so whomper damper it is.