PeterD

TVWBB Super Fan

So, my luck ran out in NJ this week trying to get a full Choice grade packer. Sussex Meat said there isn't one to be had in NJ and hasn't been for weeks. So off I went to Western Beef in NYC. First place had a scrawny one that I passed on, but the second place had a couple of reasonably-OK packers size-wise, but two problems presented themselves here that I'd like advice on.

First, it's only Select grade. That's a very bottom-end meat market and they rarely have anything over select, but it's all cheap, in keeping with their clientelle's needs. Is there any possibility of getting good eats out of this grade?

Second, even the best one had a thin flat and huge slabs of hard fat all over the top and sides of the point. I grabbed one that had the thickest flat, with a pre-trim weight of 12.46#. I suspect pre-cook will be under 12 as it's got a lot of hard fat.

My problems in the past have always been that the thin flats are shoe leather when the main bulk of the brisket is probe tender. I put my temp. probe in the top of the brisket on the sloped part of the point, about a third of the way down from the top of the point, and when that whole area is tender almost the whole flat is grey and stringy and falling apart.

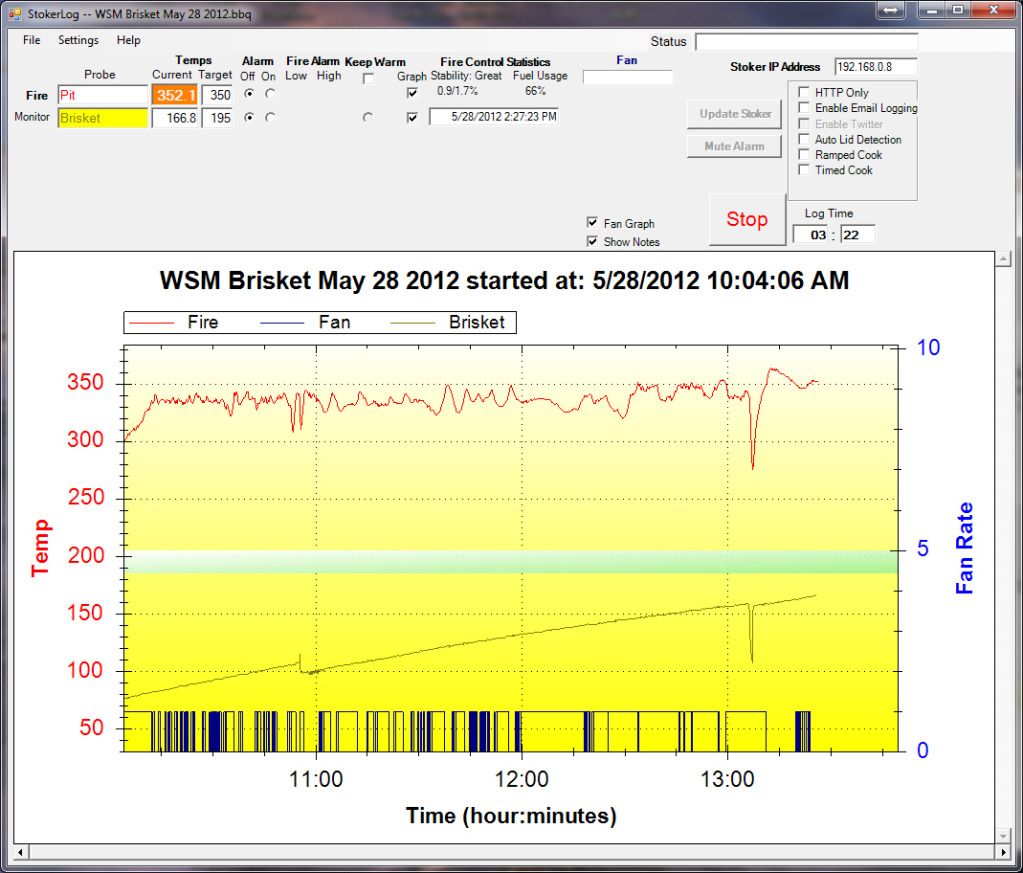

My planned cooking method is 240 degrees for as long as it takes over Comp K with white oak and either apple or cherry. No wet rub, but I plan to do an inject with Fab-lite. For a rub I'm just planning on a simple dalmation rub with a touch of Ancho for smoke, a dash of Cayenne for heat and maybe some allspice. Coffee, too, maybe??

Any thoughts on getting this bad boy tender throughout with little waste?

First, it's only Select grade. That's a very bottom-end meat market and they rarely have anything over select, but it's all cheap, in keeping with their clientelle's needs. Is there any possibility of getting good eats out of this grade?

Second, even the best one had a thin flat and huge slabs of hard fat all over the top and sides of the point. I grabbed one that had the thickest flat, with a pre-trim weight of 12.46#. I suspect pre-cook will be under 12 as it's got a lot of hard fat.

My problems in the past have always been that the thin flats are shoe leather when the main bulk of the brisket is probe tender. I put my temp. probe in the top of the brisket on the sloped part of the point, about a third of the way down from the top of the point, and when that whole area is tender almost the whole flat is grey and stringy and falling apart.

My planned cooking method is 240 degrees for as long as it takes over Comp K with white oak and either apple or cherry. No wet rub, but I plan to do an inject with Fab-lite. For a rub I'm just planning on a simple dalmation rub with a touch of Ancho for smoke, a dash of Cayenne for heat and maybe some allspice. Coffee, too, maybe??

Any thoughts on getting this bad boy tender throughout with little waste?