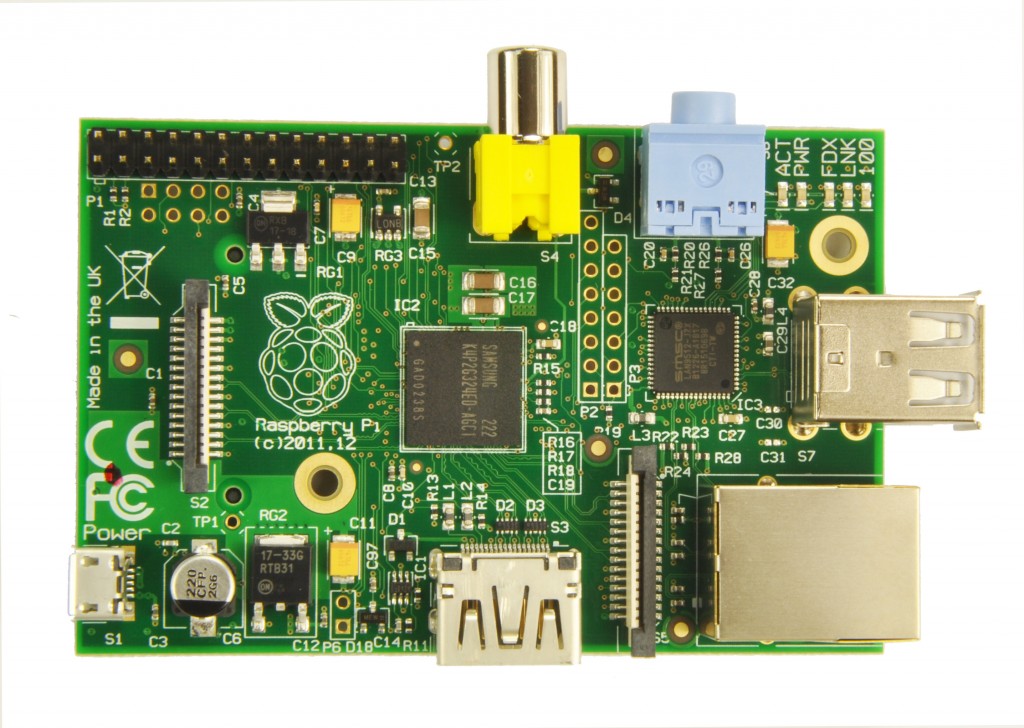

Oh, and if you swap the RCA over from the rPI, make sure you remember that you did that and don't hook the 12v fan output in through the RCA to your monitor. Oops

. Luckily mine was in manual mode at 0% PWM. Not sure if the composite is 12v tolerant, but I'd guess not. The monitor flickered, but is fine. Maybe reusing the yellow RCA jack is not the best idea. Sharpie time

FYI,

I love the fan speed bar graph, but what is the yellow line that moves around? Moving average I guess?

Still strange functionality with the Image from the 30th with respect to wifi. Does not freeze on boot, but things are not happy. ifconfig essentially freezes, but the console is still responsive.

Web interface password stuff is working well now. Updating the firmware from the web page went off without a hitch. Hopefully going to test the new SRTP 1Hz update rate shortly.

I played with the 1Hz Update rate... working well, but I was thinking that setting the minimum fan speed on the web interface was actually the SRTP* start threshold... I see that they are not the same thing.. but I don't understand why they are really different settings. If I set the min fan speed at 40%, then I command 35% in manual mode, it just spins 40%, always on. If the SRTP started at the min fan speed, and chopped up the range of 0-MIN_FAN_SPEED into the nearest "on" time per 10 seconds, you would only have to set min fan speed, not srtp start percent. In this case, 4% would be on at MIN_FAN_SPEED for 1 second, off for 10, 8% on for 2 seconds, etc. I think that is how it will work when you set the SRTP value in the firmware, but I'm wondering if you ever need them to be different numbers (min fan speed and SRTP start percent). Am I just out of it tonight?

* SRTP = Split range time proportional, which is an easy way to say "when the fan goes on and off instead of variable speed control" (I hate when people use acronyms on forums and do not define them!)