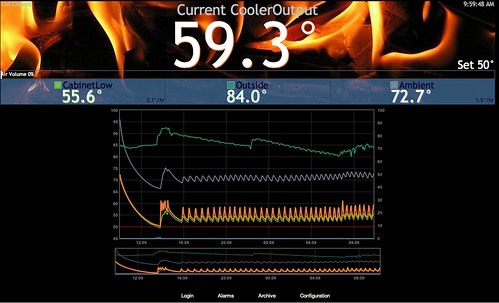

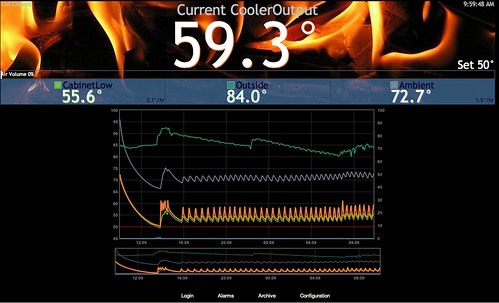

Here's a graph of my HM4.1 monitoring my newly installed 600 bottle capacity wine cabinet (a Vinotemp 600E). I'm simply monitoring the wine cabinet, and not using the HM fan control to modulate the cooling unit on this I obtained this from a friend of my father, as he no longer needed the unit. Since the cooling unit appeared to be dead, he didn't charge me for it. So, when I got it home, I took apart the cooling unit and verified that it was blowing only warm air. Given that a replacement cooler unit costs more than $1200, I decided to try to fix it before spending that cash on a new one. I ended up adding more R134a "Freon" and decided to try out the non-functioning cooler unit. After re-installing this in the cabinet, I grabbed my HM to monitor the temps and see if it could bring the unit down to around 55-60F, the optimal temp for wine.

Note that the unit is being controlled by its built in mechanical thermostat set to its lowest temperature. I placed the HM inside the cabinet with the pit probe (orange) just below the return vent of the cooling unit (a WineMate WM2500CD). As the had passed below 50F, I set the mechanical thermostat on the cooler unit a bit higher, trying to hit a range between 55F and 60F. I also used a longer probe to measure temp at the bottom (light green) and a second probe was placed outside the unit to measure my garage temps (yes, it's warm here). The large temp swing after reaching 50F was due to me opening the door on the unit to adjust the cooler unit. After this, it relatively quickly began a typical heating/cooling cycle. This morning, I bumped the thermostat up a bit to get closer to the range I'd like.

The point of this post is that these HeaterMeter units are incredibly versatile! It was so easy to use this to verify that I'd fixed the cooler unit (which just saved me $1200... thanks Bryan!). I think it would be super cool to build another HM unit purpose built for the task of controlling my wine cabinet. Seems like it would be possible to control the AC to the cooler unit using the HM, right? How does one go about this with the current software? Also, it would be super cool to have this send an email and/or SMS warning if the unit exceeded a certain temp. It would also be cool to be able to measure longer times (say over a few weeks instead of just 24h) to keep track of the cabinet performance as the weather changes.

Of course, I'd also like to do something similar for a fermentation controller for beer brewing, so I'd love to see how this is done if anyone has tried.

Note that the unit is being controlled by its built in mechanical thermostat set to its lowest temperature. I placed the HM inside the cabinet with the pit probe (orange) just below the return vent of the cooling unit (a WineMate WM2500CD). As the had passed below 50F, I set the mechanical thermostat on the cooler unit a bit higher, trying to hit a range between 55F and 60F. I also used a longer probe to measure temp at the bottom (light green) and a second probe was placed outside the unit to measure my garage temps (yes, it's warm here). The large temp swing after reaching 50F was due to me opening the door on the unit to adjust the cooler unit. After this, it relatively quickly began a typical heating/cooling cycle. This morning, I bumped the thermostat up a bit to get closer to the range I'd like.

The point of this post is that these HeaterMeter units are incredibly versatile! It was so easy to use this to verify that I'd fixed the cooler unit (which just saved me $1200... thanks Bryan!). I think it would be super cool to build another HM unit purpose built for the task of controlling my wine cabinet. Seems like it would be possible to control the AC to the cooler unit using the HM, right? How does one go about this with the current software? Also, it would be super cool to have this send an email and/or SMS warning if the unit exceeded a certain temp. It would also be cool to be able to measure longer times (say over a few weeks instead of just 24h) to keep track of the cabinet performance as the weather changes.

Of course, I'd also like to do something similar for a fermentation controller for beer brewing, so I'd love to see how this is done if anyone has tried.