Justin Dietz

New member

So finally got my first test run in right now.

I have a Broil King Keg.

Using newest Heatermeter with Microdamper....ALL DEFAULTS.

I used to own a Pitmaster IQ120. Figured i use my same technique.....which is if i wanted 225...i started with my set temp to 200.....and usually it would overshoot it a bit. But then I'd set to 225 and it would level right where i want it.

I set Heatermeter for 200. Well it hit 200 and way overshot it! I am now at about 270.

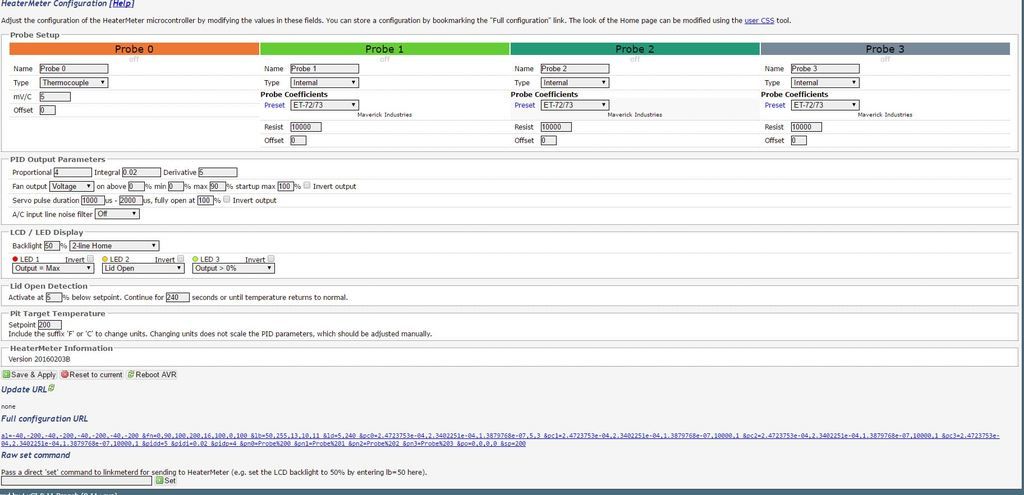

I assumed as the temp got closer to 200 that the fan would turn off and on a few times and slowly approach 200. It seemed to continue to blow 100% until reaching 200. I am guessing this is just maybe a setting or configuration thing I am missing.

Can someone offer any advice? I'd really appreciate it.

I have a Broil King Keg.

Using newest Heatermeter with Microdamper....ALL DEFAULTS.

I used to own a Pitmaster IQ120. Figured i use my same technique.....which is if i wanted 225...i started with my set temp to 200.....and usually it would overshoot it a bit. But then I'd set to 225 and it would level right where i want it.

I set Heatermeter for 200. Well it hit 200 and way overshot it! I am now at about 270.

I assumed as the temp got closer to 200 that the fan would turn off and on a few times and slowly approach 200. It seemed to continue to blow 100% until reaching 200. I am guessing this is just maybe a setting or configuration thing I am missing.

Can someone offer any advice? I'd really appreciate it.