Dominick A

TVWBB Fan

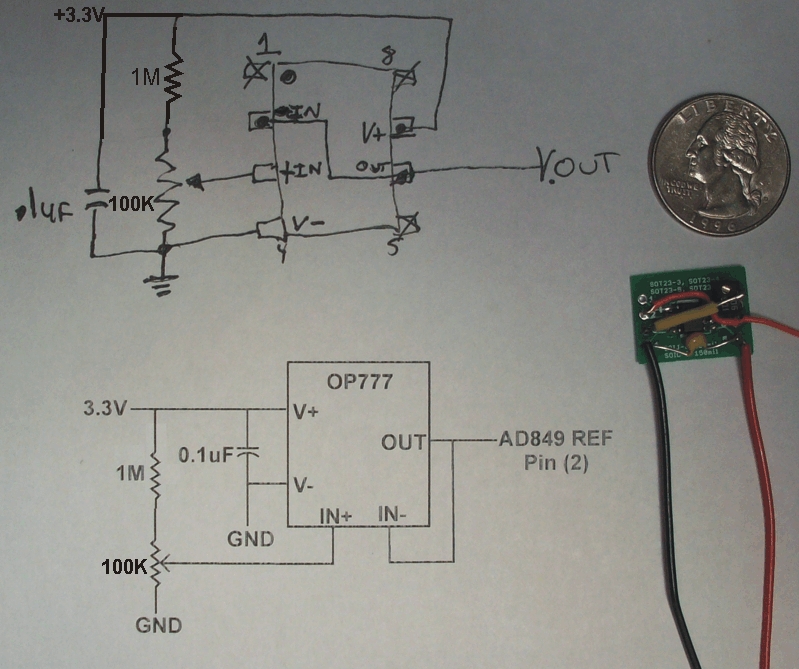

My RDTC build was successful to the point that I got a solid reading on the TC and food probes while connected to my heatermeter. Along the way, I needed to remove the potentiometer, and in doing so ripped off the top right trace. After getting my TC readings squared away, I reinstalled the potentiometer and connected the broken trace over to the 1M resistor. I also removed the solder bridge I had placed in the top left traces labeled REFG.

After hooking things back up, the RDTC read no pit probe when no pit probe was plugged in. When I plugged it in, it read 38 degrees. I think I read this is the low point of the TC. This did not change when adjusting the potentiometer. Here is a pic of my board. Any ideas what's going on here or how I should troubleshoot?

https://drive.google.com/file/d/0BzSBmZGY0VqYcF9iRkJmZTRQS2M/view?usp=sharing

After hooking things back up, the RDTC read no pit probe when no pit probe was plugged in. When I plugged it in, it read 38 degrees. I think I read this is the low point of the TC. This did not change when adjusting the potentiometer. Here is a pic of my board. Any ideas what's going on here or how I should troubleshoot?

https://drive.google.com/file/d/0BzSBmZGY0VqYcF9iRkJmZTRQS2M/view?usp=sharing