I figured out how to select and hide various pieces. However I do not see any type of description of the various parts. In the browser tree they are named things like "ACAD_FREEWAY_COMPONENT_55_HPI-4.1-v1.dwg…" I have attached a screenshot to prove I am not just being lazy. Maybe it is because I am running IF on a Mac but like I said earlier it will not run on my Windows 8.1 PC.

Clicking through the various levels of the browser does not give me any type of description either. Maybe I am missing something obvious.

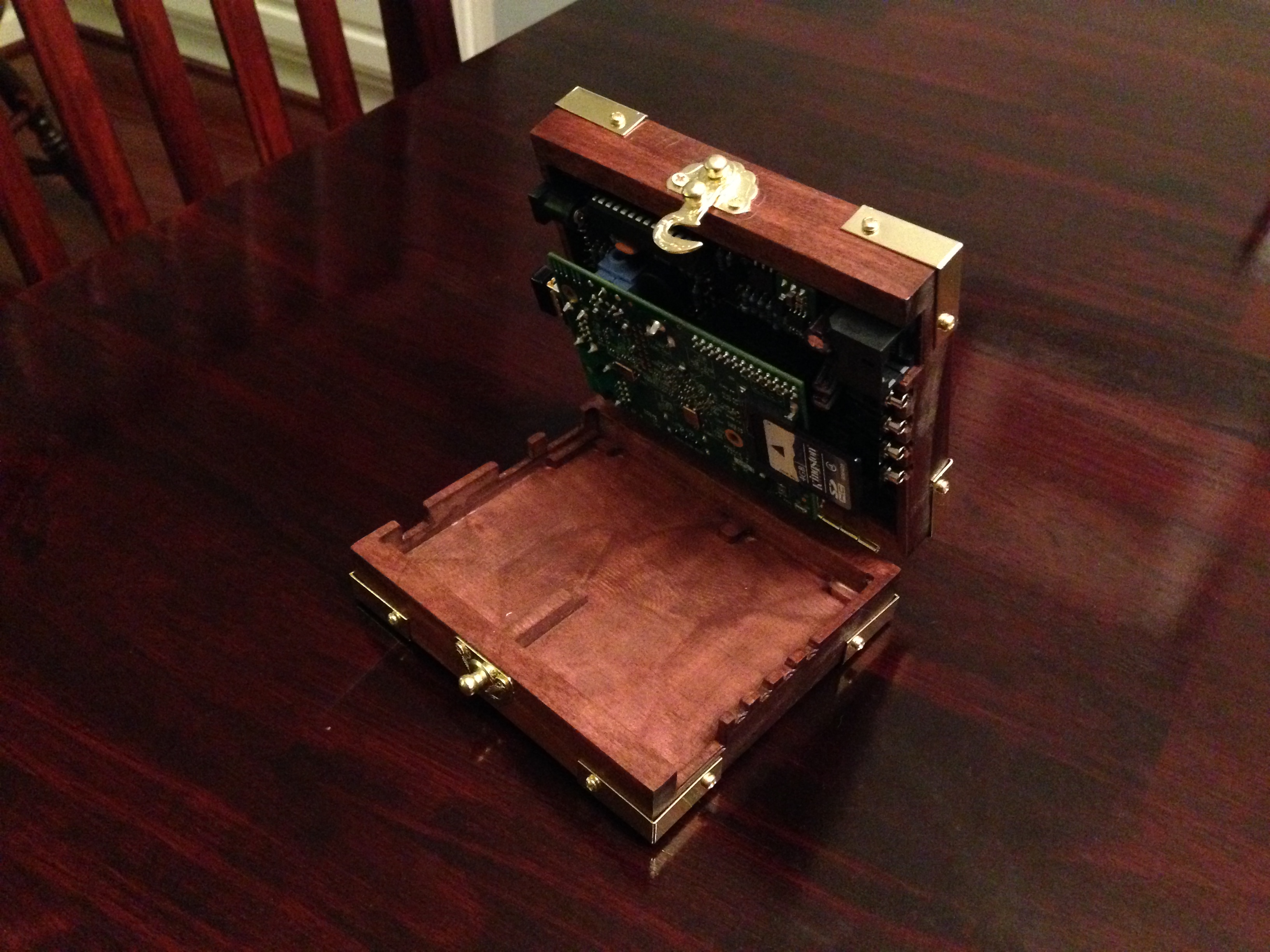

This is my first attempt at posting a pic from picasa, I can see it. Let me know if it isn't showing up for anyone else.

Clicking through the various levels of the browser does not give me any type of description either. Maybe I am missing something obvious.

This is my first attempt at posting a pic from picasa, I can see it. Let me know if it isn't showing up for anyone else.

Last edited: