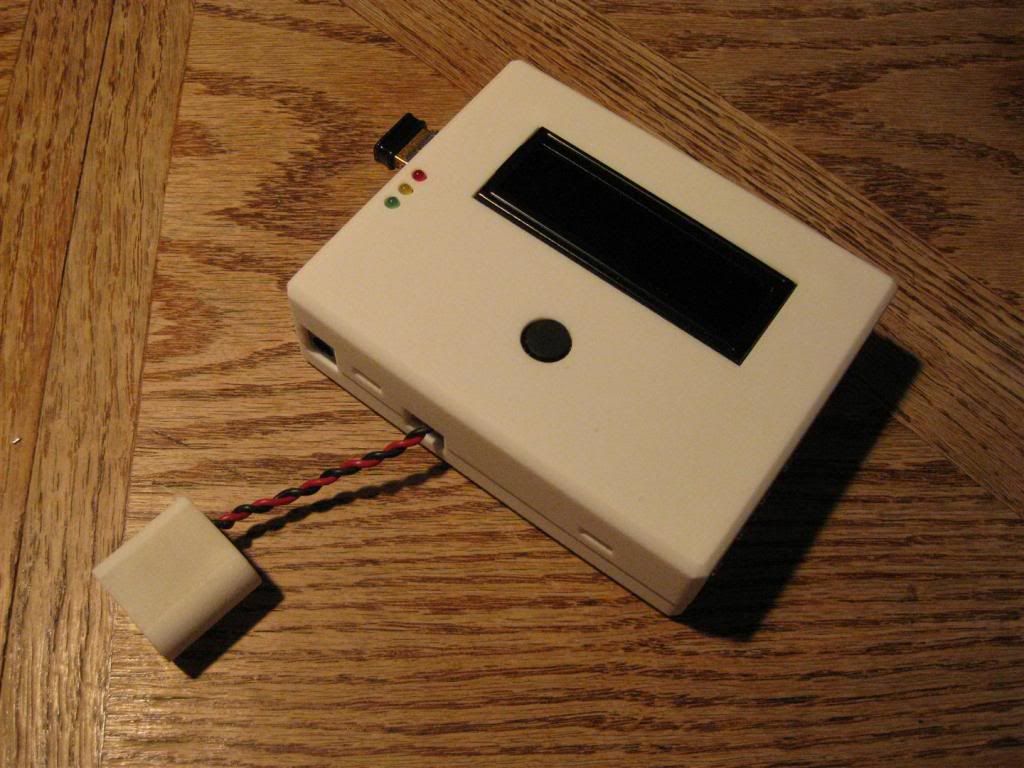

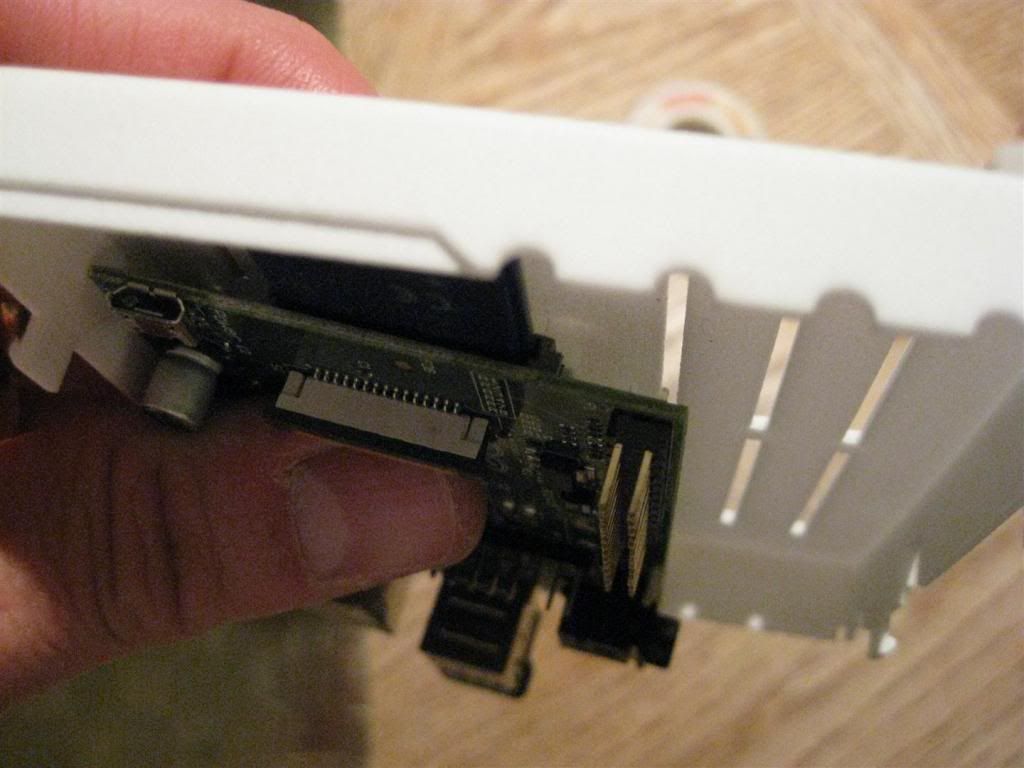

This thread is for discussion and updates of the Heatermeter v4 with raspberry pi 3D print case. The source files were created in autodesk123d and can be found below. You can PM me or Matt (M Miller) to purchase a case. Available colors are: black, red, ivory/white, silver, orange, blue, green. This case requires that the rca jack on the rpi be removed so that the boards come into maximum contact. The unit of measure for the .stl files is in mm and the LEDs should be mounted so that the bottom of the LED is positioned 7 mm above the HM PCB.

Source files were created in autodesk software which can be found here or here.

We will continue to update this post with new versions of the case as they come out.

UPDATE 9/09/13 Version 3.6

Chamfer added to all edges to more closely resemble the initial concept of the case. Versions included for Rpi-A as well as addition of a cat5e or RJ11 jack for servo/fan combo's. Cat5e or RJ11 jack is TECH brand from home depot.

Source files

UPDATE 7/06/13 Version 3.4

Square form factor with through and through screw holes and nut traps located on the bottom of the case. Tongue and groove guides were added for greater alignment stability. Button hole recessed for greater accessibility.

Source files

.123d

UPDATE 6/25/13 Version 3

Square form factor with through and through screw holes and nut traps located on the bottom of the case. Tongue and groove guides were added for greater alignment stability.

Source files

.123d

Top.stl

Bottom.stl

UPDATE 6/22/13 Version 2

There has been another case update to a more square design, reminiscent of the original case, but maintaining the use of screws for closure. Nut traps were placed inside the case.

Source files

.123d

UPDATE 2/13/13 Version 1

There has been a considerable amount of revision and update of the case design since it's original release in October 2012. The original design was created for commercial selective laser sintering printers with the goal of minimizing plastic volume to keep costs down. This price for this case still ran around $60 so alternative methods were sought. The pictures and files for the original case can be found at the bottom of the post for those still interested.

After some experimentation, M Miller came up with a more robust redesign that is suitable for printing using DIY fused deposition printers (aka repraps). Mounting holes were added to the back of the case and there is also a footed version that can stand upright:

Source files

github

Original Prototype (Version 0)

Only suitable for selective laser sintering (Shapeways, etc.)

Source files

Bottom.stl

Top.stl

Source files were created in autodesk software which can be found here or here.

We will continue to update this post with new versions of the case as they come out.

UPDATE 9/09/13 Version 3.6

Chamfer added to all edges to more closely resemble the initial concept of the case. Versions included for Rpi-A as well as addition of a cat5e or RJ11 jack for servo/fan combo's. Cat5e or RJ11 jack is TECH brand from home depot.

Source files

UPDATE 7/06/13 Version 3.4

Square form factor with through and through screw holes and nut traps located on the bottom of the case. Tongue and groove guides were added for greater alignment stability. Button hole recessed for greater accessibility.

Source files

.123d

UPDATE 6/25/13 Version 3

Square form factor with through and through screw holes and nut traps located on the bottom of the case. Tongue and groove guides were added for greater alignment stability.

Source files

.123d

Top.stl

Bottom.stl

UPDATE 6/22/13 Version 2

There has been another case update to a more square design, reminiscent of the original case, but maintaining the use of screws for closure. Nut traps were placed inside the case.

Source files

.123d

UPDATE 2/13/13 Version 1

There has been a considerable amount of revision and update of the case design since it's original release in October 2012. The original design was created for commercial selective laser sintering printers with the goal of minimizing plastic volume to keep costs down. This price for this case still ran around $60 so alternative methods were sought. The pictures and files for the original case can be found at the bottom of the post for those still interested.

After some experimentation, M Miller came up with a more robust redesign that is suitable for printing using DIY fused deposition printers (aka repraps). Mounting holes were added to the back of the case and there is also a footed version that can stand upright:

Source files

github

Original Prototype (Version 0)

Only suitable for selective laser sintering (Shapeways, etc.)

Source files

Bottom.stl

Top.stl

Last edited: