RalphTrimble

TVWBB Diamond Member

I had improperly posted this topic in the development log for discussion, I have made some initial findings so I decided to post a fresh thread here...

I have been experiencing some crazy servo behavior when running the servo over a very long CAT5 cable (~50ft I would guess). The servo would spasm rapidly at times, the longer the cable the more likely it would happen. Doing some reading up on servos I found that there isn't much room for error in the signal when you run a 3.3v controller (our ATMega) with a 5v servo, it is much better to match the control line voltage to the servo voltage. In some cases a servo booster circuit is used to overcome this sort of problem.

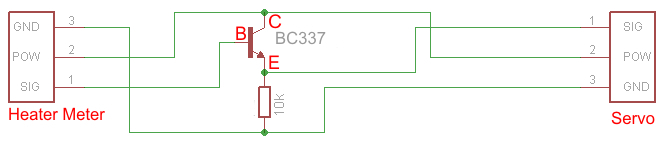

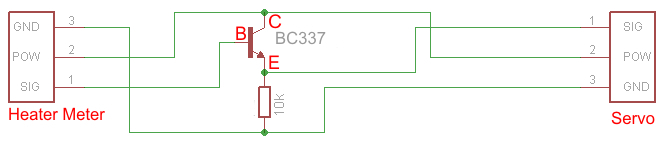

I looked up some servo booster circuits and decided to test the most simple form, using one NPN transistor and a 10K resistor. Since I have in stock extra BC337 transistors from my HM build as well as 10K resistors I decided to give these parts a go.

Here is a diagram of the very simple circuit I am testing:

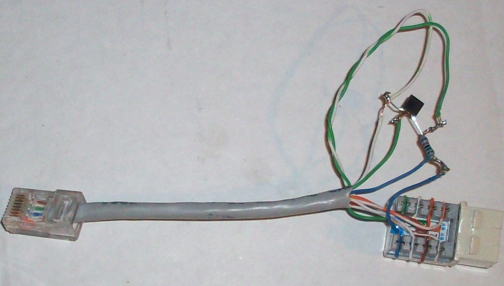

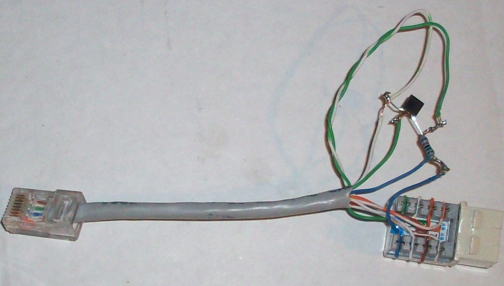

Here is a picture of the actual components:

Initial tests went really well. When I run the servo over the long cable the servo goes nuts, after I insert the booster inline the servo is rock solid!

Here is a video of the test. I start out with no booster and the problem will be obvious, then I insert the booster and the problem goes away. While the booster is installed I move the servo up and down in 5% increments a bit, then in 1% increments, finally I remove the booster for the last few seconds of the video. Movement is nice and solid and accurate with the booster, not so much without.

This simple booster solved my problem with the long cable run, haven't tested the limits of how long a run will work, but this is definitely a big improvement. If there is room on the HM board for one more transistor and a resistor it would be nice if this booster could be included in the next build.

I have been experiencing some crazy servo behavior when running the servo over a very long CAT5 cable (~50ft I would guess). The servo would spasm rapidly at times, the longer the cable the more likely it would happen. Doing some reading up on servos I found that there isn't much room for error in the signal when you run a 3.3v controller (our ATMega) with a 5v servo, it is much better to match the control line voltage to the servo voltage. In some cases a servo booster circuit is used to overcome this sort of problem.

I looked up some servo booster circuits and decided to test the most simple form, using one NPN transistor and a 10K resistor. Since I have in stock extra BC337 transistors from my HM build as well as 10K resistors I decided to give these parts a go.

Here is a diagram of the very simple circuit I am testing:

Here is a picture of the actual components:

Initial tests went really well. When I run the servo over the long cable the servo goes nuts, after I insert the booster inline the servo is rock solid!

Here is a video of the test. I start out with no booster and the problem will be obvious, then I insert the booster and the problem goes away. While the booster is installed I move the servo up and down in 5% increments a bit, then in 1% increments, finally I remove the booster for the last few seconds of the video. Movement is nice and solid and accurate with the booster, not so much without.

This simple booster solved my problem with the long cable run, haven't tested the limits of how long a run will work, but this is definitely a big improvement. If there is room on the HM board for one more transistor and a resistor it would be nice if this booster could be included in the next build.

Last edited: