You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HeaterMeter Hardware v4.3.3, v4.3.4, v4.3.5, v4.3.6

- Thread starter Bryan Mayland

- Start date

Search mouser for AD8495CRMZ and there should be some in stock. It’s basically a more expensive version of the same part as the error tolerances are much lower. The AD8495ARMZ version looks to be out of stock everywhere right now.

Data sheet here.

I mean how and where to install the parts on the PCB, the AD8495ARMZ part I ordered from a dutch company

Steve_M

TVWBB Guru

I mean how and where to install the parts on the PCB, the AD8495ARMZ part I ordered from a dutch company

At the bottom of https://github.com/CapnBry/HeaterMeter/wiki/HeaterMeter-4.3-Assembly

Click the link to the album.

The thermocouple SMD parts are in the bottom right of this pic

https://photos.google.com/share/AF1...?key=SDYyajFQWjdoTlUwTHg5OHluc194MlZKNzNBVEpn

Bryan Mayland

TVWBB Hall of Fame

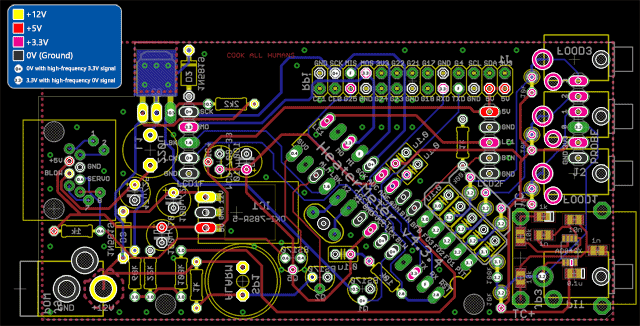

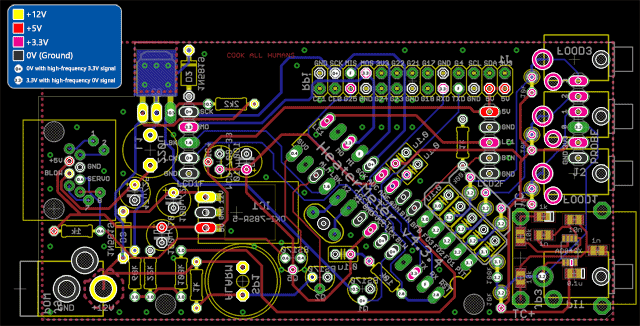

Just pushed some updates to the HeaterMeter v4.3 board file, the new HeaterMeter v4.3.4! This is just a bunch of minor tweaks to the board parameters simply to make it easier to solder. I think anyone who has put a v4.3 device together has been stymied by the small pads and giant heat-absorbing ground plane that makes them less than joyful to solder. I have to hold a soldering iron on the ground pads a good 5 seconds before I have any chance of getting solder to flow. This update makes those pads bigger and also backs the ground plane away from ground pins so it doesn't suck all the heat away before the solder can flow. You can see the difference in pad sizes looking at the updated 434 voltage diagram.

-- Base Board --

The LCD board was already in a good place but I made the parameters match the base, and the labels on the signals match the names on the base board as well. It just makes them easier to follow from one board to the other. The shift register also got labels on the signals so it is easier to check continuity.

-- LCD Board --

-- Base Board --

- Increase annular ring to 14mil (from 7)

- Increase thermal isolation to 15mil (from 10)

- Chamfer corners on front edge

- Rearrange power MOSFET footprint to sink more heat into board

- Add TC+/- indicators to thermocouple pins

- More direct path for 5V out and 12V in / blower current return path (swap D3 and R21)

The LCD board was already in a good place but I made the parameters match the base, and the labels on the signals match the names on the base board as well. It just makes them easier to follow from one board to the other. The shift register also got labels on the signals so it is easier to check continuity.

-- LCD Board --

- Add word "CONTRAST" by contrast pot

- Increase annular ring to 14mil (from 12)

- Increase thermals to 15mil (from 10)

- Redo LCD1M labels to match labels of MOSI/SCK/etc on main

- Add pin labels to shift register

John Bostwick

TVWBB Wizard

Is 4 probes the max for this setup? Just checking to see if it has been modified to add a 5th. Or maybe have the 4 probes, and ambient temp as the 5th somehow.

Thanks.

The Heatermeter will most likely always be 1 pit probe(thermocouple or probe) and 3 meat probes.

Bryan Mayland

TVWBB Hall of Fame

Yeah all the ADC ports are in use currently so there's no place to plug them into. Also, all the UI and backend expect there to be just 4 total probes so the layouts are all fixed with this in mind.

So I would need to use a thermocouple to get 4 probes, or can it be set to use 4 of the standard type probes?The Heatermeter will most likely always be 1 pit probe(thermocouple or probe) and 3 meat probes.

Yeah all the ADC ports are in use currently so there's no place to plug them into. Also, all the UI and backend expect there to be just 4 total probes so the layouts are all fixed with this in mind.

Thanks guys.

Bryan Mayland

TVWBB Hall of Fame

HeaterMeters have 4 probes, and the standard board has the pit probe able to be built as either a thermocouple or thermistor.

HeaterMeters have 4 probes, and the standard board has the pit probe able to be built as either a thermocouple or thermistor.

Thanks. I just read up on the differences between the thermocouple and thermistor probes. The faster response, higher accuracy, and possibly higher temp range with a thinner profile are very nice thermocouple features. I am guessing by what I have seen available that about all the consumer smoker thermometers use thermistor probes. Which means you could, depending on probe choice, get more accurate pit readings with the heatermeter with thermocouple. Am I thinking correctly here?

Bryan Mayland

TVWBB Hall of Fame

Eeee it is possible that the accuracy could be better but they are practically very close. The precision of the thermoworks thermistor probe at 225F is 0.28F, compared to 0.38F for a thermocouple. However, at 300F or 60F the thermistor has a precision of 0.68F but the thermocouple is still 0.38F so there are tradeoffs in precision depending on temperature. The thermocouple's signal is lower voltage as well so it could be subject to greater noise. The thermocouple is easier to calibrate if you're striving for ultimate accuracy using a slope-offset (mv/C and offset in HeaterMeter) compared to the thermistor's second order natural log function which is only calibrated using a hundred+ data points and curve fitting. In short, both do a fine job of reading the temperature within a couple of degrees in practice.

Where I think the thermocouple shines is that I've had mine in the big green egg left outside for years now and it still works perfectly. Their construction is very robust, and I can fire the grill up to 900F if I wanted to without damaging anything. It is integrated into my grill so that's one fewer thing I have to carry out when setting up and I don't have to remove it depending on what is being cooked and it's fine if the 100% Florida humidity gets all over it every day because it won't fail due to moisture intrusion.

Where I think the thermocouple shines is that I've had mine in the big green egg left outside for years now and it still works perfectly. Their construction is very robust, and I can fire the grill up to 900F if I wanted to without damaging anything. It is integrated into my grill so that's one fewer thing I have to carry out when setting up and I don't have to remove it depending on what is being cooked and it's fine if the 100% Florida humidity gets all over it every day because it won't fail due to moisture intrusion.

Where I think the thermocouple shines is that I've had mine in the big green egg left outside for years now and it still works perfectly. Their construction is very robust, and I can fire the grill up to 900F if I wanted to without damaging anything. It is integrated into my grill so that's one fewer thing I have to carry out when setting up and I don't have to remove it depending on what is being cooked and it's fine if the 100% Florida humidity gets all over it every day because it won't fail due to moisture intrusion.

I didn't realize you could do that. It appears the thermistor would do what I want, but now I am thinking about the bit about leaving it in the smoker. Thanks for all the info.

I already have a Pi 3 and soldering station, so I am leaning towards the HeaterMeter. I was looking at the CyberQ, but doesn't this do everything that it can?

I was looking at the CyberQ, but doesn't this do everything that it can?

Yes and way more if you can do a little scripting.

RalphTrimble

TVWBB Diamond Member

HM does more than any commercial controller in so many ways. The only thing I have seen on a commercial controller that I envy is the auto tune for PID settings. We can't seem to get there with the HM for some reason, IDK how they do it, or how accurate the auto tune is on that controller?

One thing no other controller does is allow a servo damper control, huge step forward IMHO....

One thing no other controller does is allow a servo damper control, huge step forward IMHO....

What is the replacement part for the 5 Pin Female Header ( 3M -- 960105-6303-AR) on the LCD board? According to Mouser and DigiKey the part is obsolete. They had no exact replacements and I was concerned about choosing one similar without checking here first.

I searched the forum and Wiki and couldn't find an answer.

Thanks.

-Dave

I searched the forum and Wiki and couldn't find an answer.

Thanks.

-Dave

Bryan Mayland

TVWBB Hall of Fame

You're the second person to ask about that this week, in that it was just brought to my attention a few days ago that the part is now obsolete. I found the Harwin M20-7820542 which looks right but I haven't had a chance to get any to test with. I just had a Mouser order last week though so it will be a couple months before I have another order to include them in. I have a whole bag full of connectors that I thought met proper specs before though so proceed with caution. These run of the mill pinheaders are not easy to find and are hella expensive to boot.

The other option is eBay where they are more common. Just search for "1x5 female header", although looking now I don't see any that ship from the US. Be careful to not get "dupont" headers as those are the plastic shells for connecting wires.

The other option is eBay where they are more common. Just search for "1x5 female header", although looking now I don't see any that ship from the US. Be careful to not get "dupont" headers as those are the plastic shells for connecting wires.

Thanks for the info Bryan.

The Harwin looks pretty good. Weird that it didn't show up in my replacement part search. What would most likely be the problem areas/concerns for a new part?

Since it is a basic connector, I assume it is the plastic dimensions and pitch. All of those look good compared to the 3M.

-Dave

The Harwin looks pretty good. Weird that it didn't show up in my replacement part search. What would most likely be the problem areas/concerns for a new part?

Since it is a basic connector, I assume it is the plastic dimensions and pitch. All of those look good compared to the 3M.

-Dave

John Bostwick

TVWBB Wizard

John Bostwick

TVWBB Wizard

https://www.arrow.com/en/products/960105-6202-ar/3m

Arrow has free shipping, and are fast, but pay a little more

Arrow has free shipping, and are fast, but pay a little more