Aaron Morris

TVWBB Member

Ok,

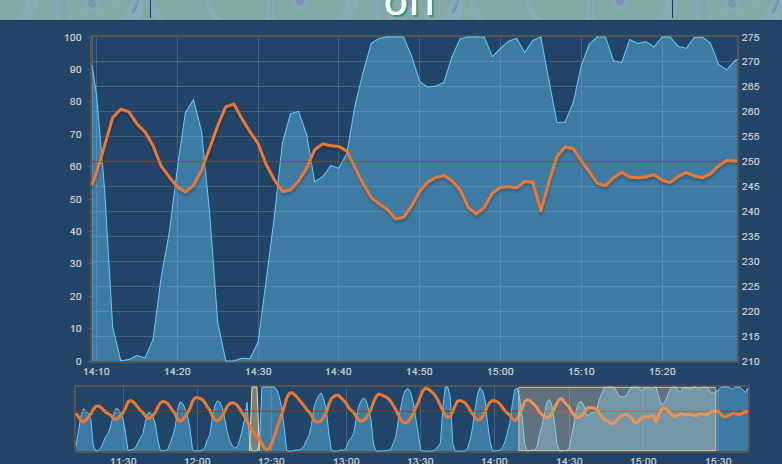

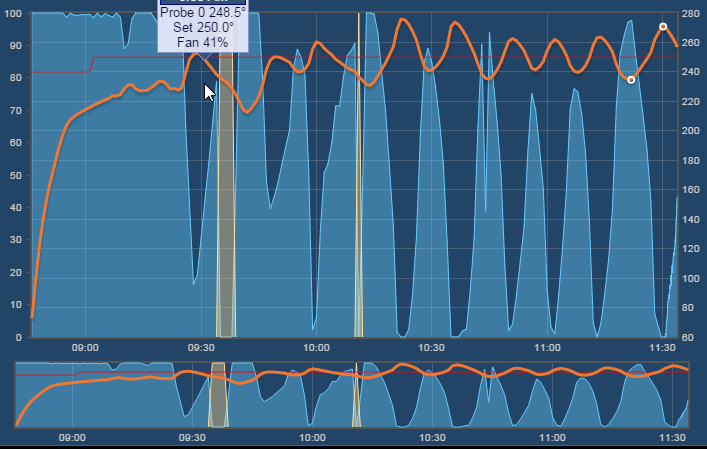

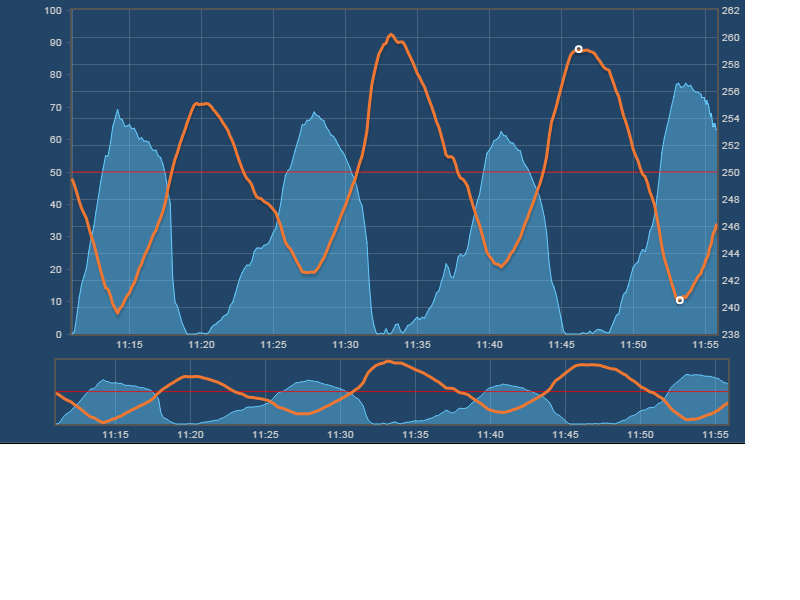

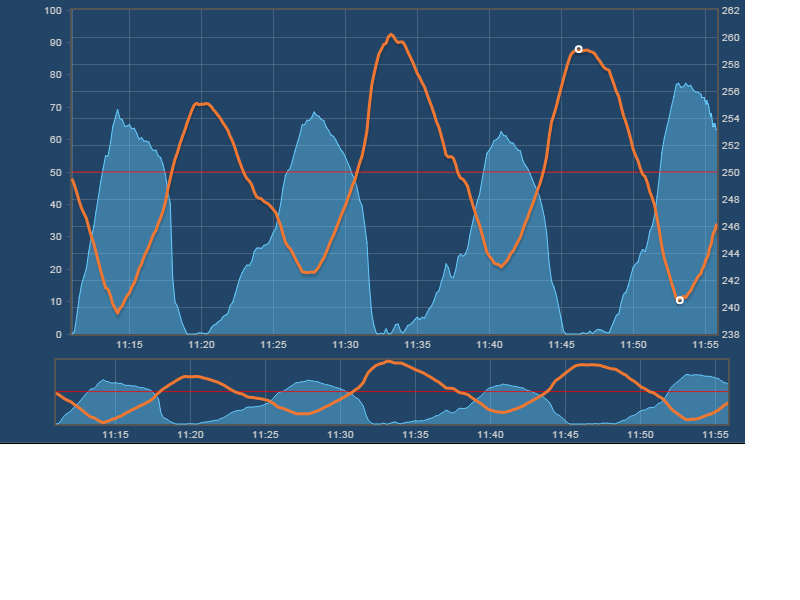

So I'm testing my Heatermeter with mini Mini WSM. This is what I'm seeing:

I'm running with 10% blower on all the time and 20% startup max. When I had it set at 225 degrees, it was running perfect, but going to 250 causes this sinusoidal. This is with a Rotodamper, 3/4" inlet to the side of the grill.

Should I try for just fan on at max only?

Thanks!

So I'm testing my Heatermeter with mini Mini WSM. This is what I'm seeing:

I'm running with 10% blower on all the time and 20% startup max. When I had it set at 225 degrees, it was running perfect, but going to 250 causes this sinusoidal. This is with a Rotodamper, 3/4" inlet to the side of the grill.

Should I try for just fan on at max only?

Thanks!