Dave Casazza

TVWBB Fan

Hi All,

Matt Miller and I have been playing around with getting the HM code running on the ATMega2650 platform, and I think we have done it. We made some interesting design decisions:

1) 100% compatible with the existing HM4 Arduino code base (more or less).

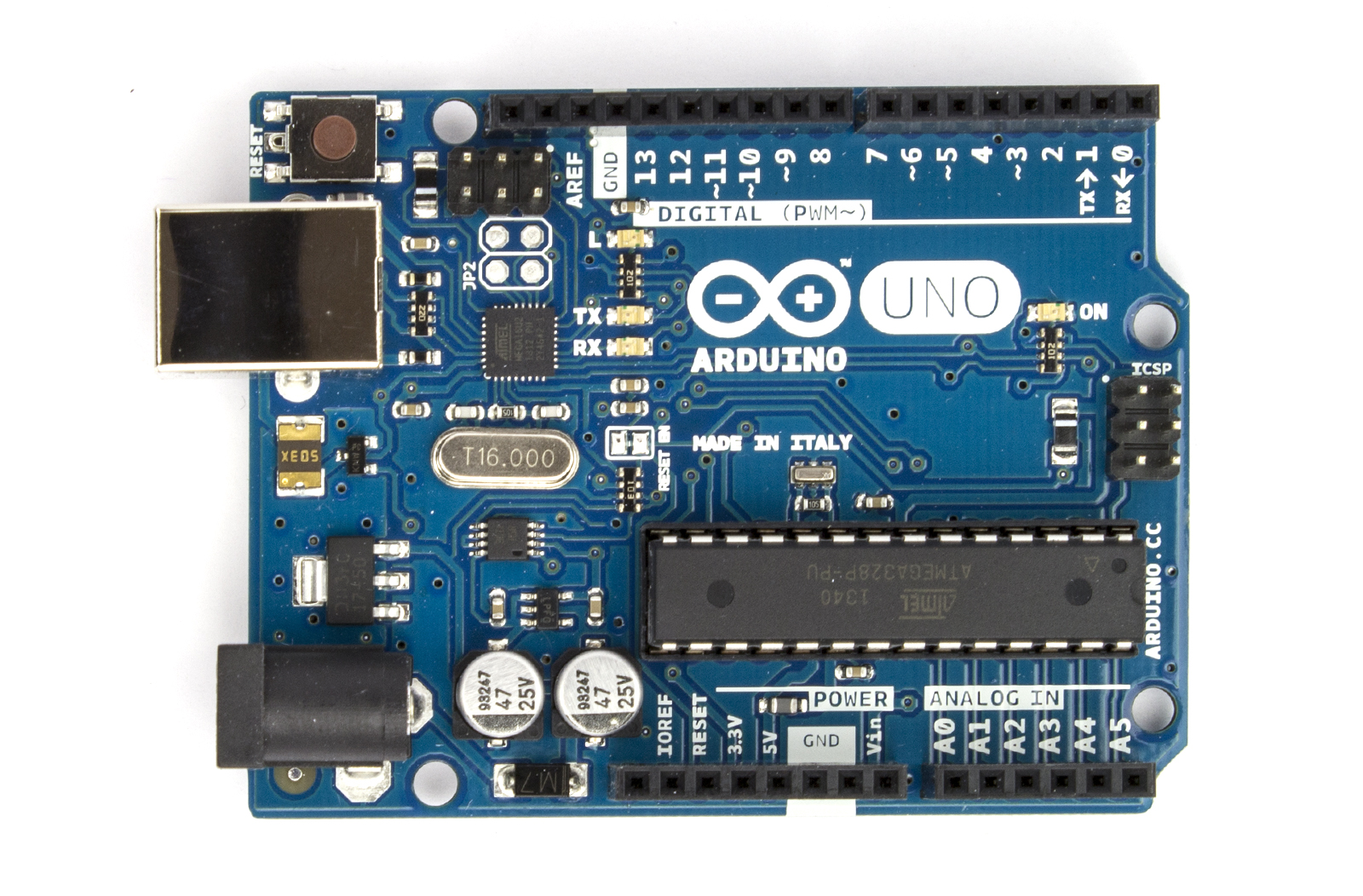

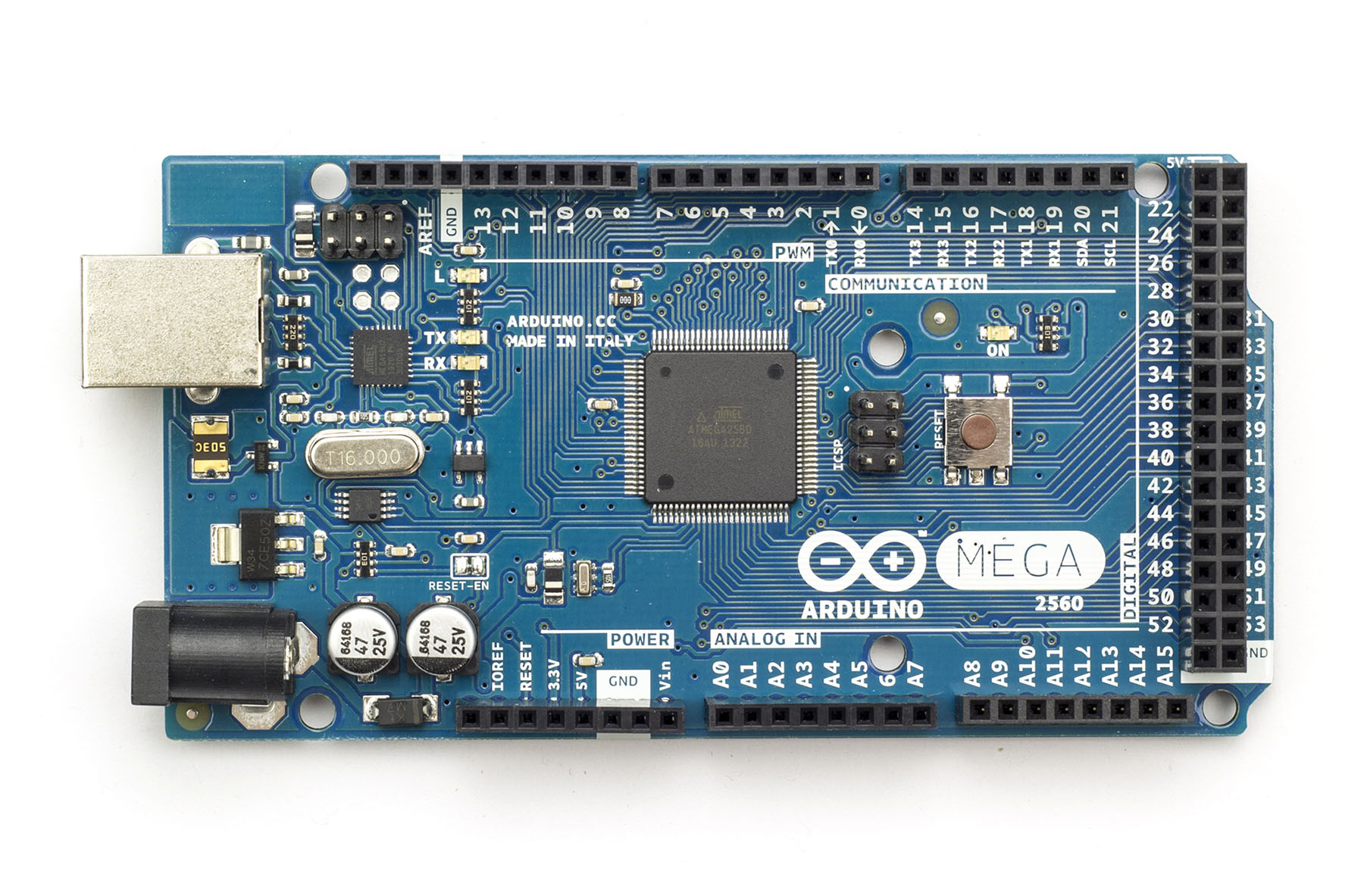

2) Moved to the ATMega2560 Platform, which permits much more code to execute (x4), and many more inputs (x4ish). This permits more inputs (rotary encoder anyone?). See http://arduino.cc/en/Main/arduinoBoardMega2560

3) Moved to a shield configuration, that mounts a motherboard shield above the ATMega2560 board.

4) Moved the logic of the blower to a daughterboard, connected via RJ45 cable. This allows us to separate/move the expensive stuff (Mega2560, candybar like display) out of the wind/rain from the blower connections and temperature monitoring logic.

5) Added to the daughterboard the ability to extend logic via separate 328P control. This permits us to load different programs on the daughterboard that can drive more stuff simultaneously. The 328P can monitor the blower output, and drive a separate servo for damper control (see picture below). In another scenario, the 328P can monitor the blower, and do precise proportional control to a zero crossing SSR (proportional control to 1/120 of a second increments (the number of times an SSR can zero cross in a second). The proportional control is very nice in controlling an electric based smoker (and probably less important for sous vide application because of the high specific heat for water).

We have figured out how to integrate the 5v logic on the mega to the 3.3 volts on the rPI, so Bryan's Raspberry PI platform works. The integration also includes the SPI logic to the rPI, but flashing the mega requires specific firmware code on the rPI codebase to support.

Here are pictures:

Motherboard Shield, running of ATMega2560 board (you can see wires connecting the shield to the RX/TX for an rPI):

Motherboard and daughterboard are connected by standard RJ45 network cables.

Daughterboard, driving both blower and servo damper:

Daughterboard, driving SSR with 1/120 sec proportional control:

I got tired of charcoal, so I built this electric smoker based on alton brown's flowerpot concept, using a 120V stove-top burner element.

Any interest in having us publishing the design? It's a way of utilizing the existing code base, but setting up the HM to move beyond the limitations of the 328P chip.

I am also happy to show more pictures of the electric flowerpot smoker design and parts if interested.

Cheers,

Dave

Matt Miller and I have been playing around with getting the HM code running on the ATMega2650 platform, and I think we have done it. We made some interesting design decisions:

1) 100% compatible with the existing HM4 Arduino code base (more or less).

2) Moved to the ATMega2560 Platform, which permits much more code to execute (x4), and many more inputs (x4ish). This permits more inputs (rotary encoder anyone?). See http://arduino.cc/en/Main/arduinoBoardMega2560

3) Moved to a shield configuration, that mounts a motherboard shield above the ATMega2560 board.

4) Moved the logic of the blower to a daughterboard, connected via RJ45 cable. This allows us to separate/move the expensive stuff (Mega2560, candybar like display) out of the wind/rain from the blower connections and temperature monitoring logic.

5) Added to the daughterboard the ability to extend logic via separate 328P control. This permits us to load different programs on the daughterboard that can drive more stuff simultaneously. The 328P can monitor the blower output, and drive a separate servo for damper control (see picture below). In another scenario, the 328P can monitor the blower, and do precise proportional control to a zero crossing SSR (proportional control to 1/120 of a second increments (the number of times an SSR can zero cross in a second). The proportional control is very nice in controlling an electric based smoker (and probably less important for sous vide application because of the high specific heat for water).

We have figured out how to integrate the 5v logic on the mega to the 3.3 volts on the rPI, so Bryan's Raspberry PI platform works. The integration also includes the SPI logic to the rPI, but flashing the mega requires specific firmware code on the rPI codebase to support.

Here are pictures:

Motherboard Shield, running of ATMega2560 board (you can see wires connecting the shield to the RX/TX for an rPI):

Motherboard and daughterboard are connected by standard RJ45 network cables.

Daughterboard, driving both blower and servo damper:

Daughterboard, driving SSR with 1/120 sec proportional control:

I got tired of charcoal, so I built this electric smoker based on alton brown's flowerpot concept, using a 120V stove-top burner element.

Any interest in having us publishing the design? It's a way of utilizing the existing code base, but setting up the HM to move beyond the limitations of the 328P chip.

I am also happy to show more pictures of the electric flowerpot smoker design and parts if interested.

Cheers,

Dave

Last edited: