I'm currently using a PID from Omega with a bare thermocouple to control my temperature. It does a decent enough job but I'm intrigued by the HeaterMeter and features like the open lid detection, web interface, alarms, ramp down, cook logging, etc and I'm itching to build one.

That being said, I already have an ET-73 and I find that the probes react very slowly to changes in temperature, especially compared to the bare thermocouple I'm using with my PID that has a time constant of 0.01 seconds. I understand that this is due to the thermal mass of the Maverick probe and that it is essentially acting like a moving average filter of the temperature. What I don't know is how that would affect temperature control.

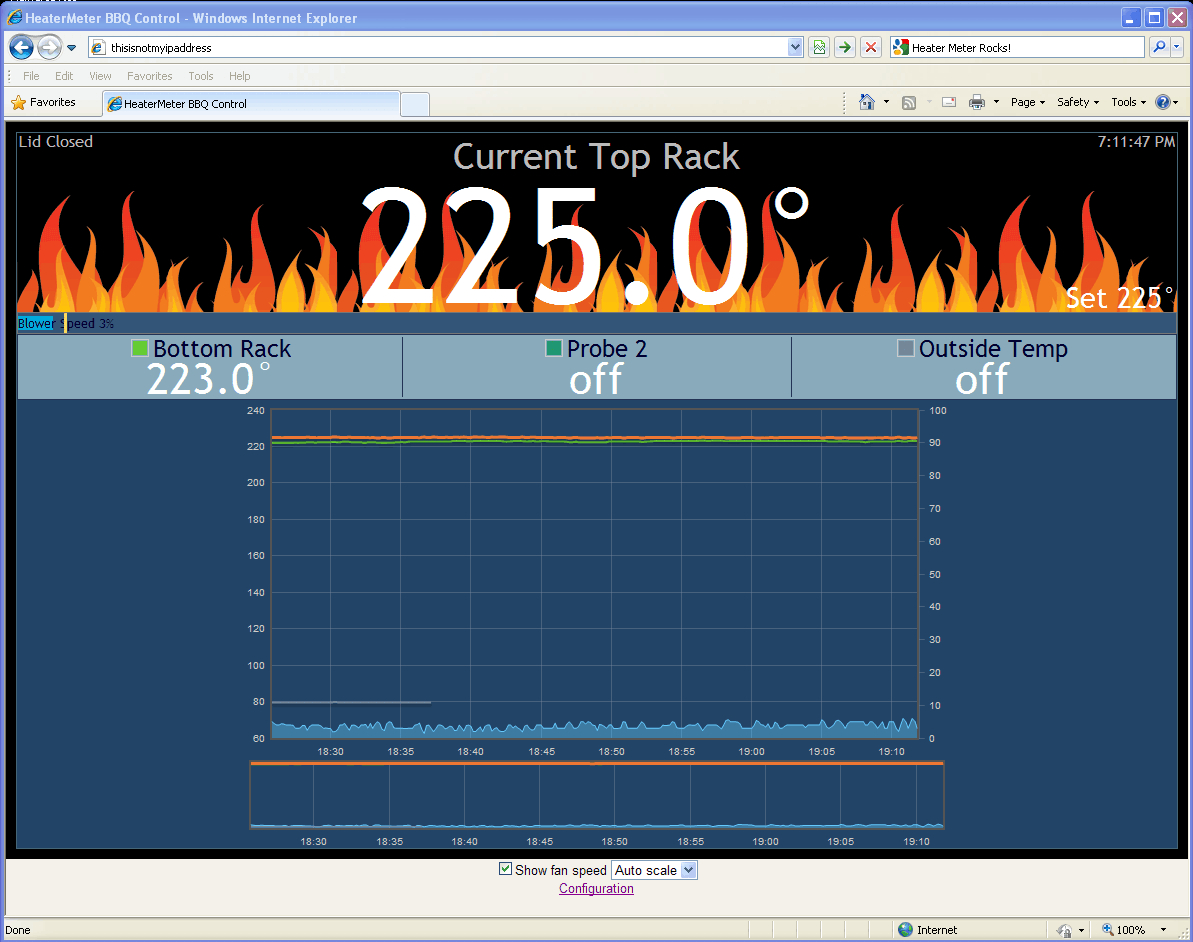

It seems like you would need to log temperature with a separate device that has a very short time constant in order to see what the effects are. Has anybody tried this? I realize that this is probably not an issue but I'm curious what you guys think about it.

That being said, I already have an ET-73 and I find that the probes react very slowly to changes in temperature, especially compared to the bare thermocouple I'm using with my PID that has a time constant of 0.01 seconds. I understand that this is due to the thermal mass of the Maverick probe and that it is essentially acting like a moving average filter of the temperature. What I don't know is how that would affect temperature control.

It seems like you would need to log temperature with a separate device that has a very short time constant in order to see what the effects are. Has anybody tried this? I realize that this is probably not an issue but I'm curious what you guys think about it.