John Bostwick

TVWBB Wizard

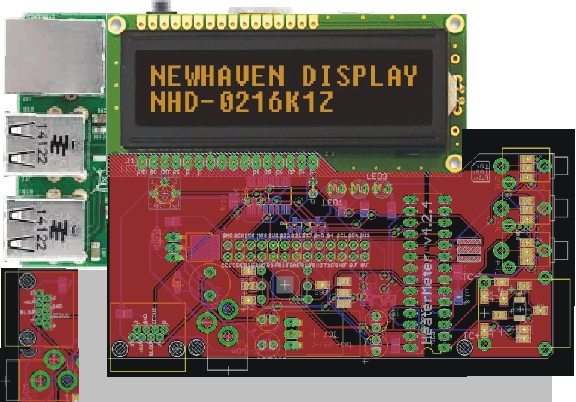

The last 3 or 4 days I have been painstakingly making a smd version of the Heatermeter and in the process have made what I think also will fit a B+. Not all the components are smd and some would not make that much difference, like the barrel caps, although you could get them in an smd version, they are expensive and not worth it.

So, I replaced all the resisters, shift resister, BS170's and 1700, diodes, 16mhz resonator, .1 caps to smd versions. I moved the RpI header 7.62mm to the left, so that the lcd does not hit the Cat5 jack on the B+. The LCD and Button have not moved. the LEDs are just below the LCD on the right. Also, I have to move the cat5 jack and AC jack to the bottom. This is actually, I think, a good place as, not as good if everything was one side though, but better then having wires on both sides.

The biggest thing is that the board atm would be about $8 cheaper for 3 of them at $34.95, and the parts, which I have not figured out yet, would be about the same cost.

I have not tested and its still in the works and very much a work in progress and its not an official HM from Bryan. But here is a pic of my sloppy eagle work, lol.

So, I replaced all the resisters, shift resister, BS170's and 1700, diodes, 16mhz resonator, .1 caps to smd versions. I moved the RpI header 7.62mm to the left, so that the lcd does not hit the Cat5 jack on the B+. The LCD and Button have not moved. the LEDs are just below the LCD on the right. Also, I have to move the cat5 jack and AC jack to the bottom. This is actually, I think, a good place as, not as good if everything was one side though, but better then having wires on both sides.

The biggest thing is that the board atm would be about $8 cheaper for 3 of them at $34.95, and the parts, which I have not figured out yet, would be about the same cost.

I have not tested and its still in the works and very much a work in progress and its not an official HM from Bryan. But here is a pic of my sloppy eagle work, lol.