Are you using solid or stranded CAT5 cable? You want solid for punch down connectors....

I've been punching down solid wire lately and haven't had any problems, but when I started out I used to cut the plastic away from the punch down knives and solder the wires on to be sure they get a good connection. I still tend to cut the plastic away from the ground on the corner and solder the wires in since there are a couple wires of different thickness that connect there, other than that punched down wires work fine for me.

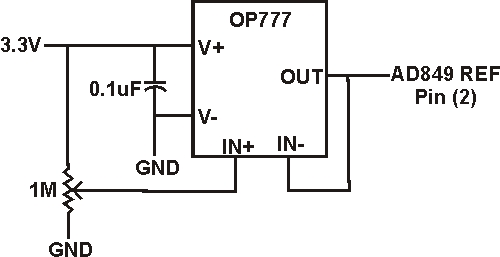

On the offset, I think if you go back to powering the amp with 3.3v your TC will read the same as the other probes. That said, I am moving in the direction of using a tunable offset voltage and then setting an offset for the TC in the HM Config so the TC will work down into the sub zero range. I hope to have the circuit posted above built up this week some time. BTW, I am going to use a multi-turn (5) potentiometer for the offset voltage adjustment for finer more gradual adjustment.