John Bostwick

TVWBB Wizard

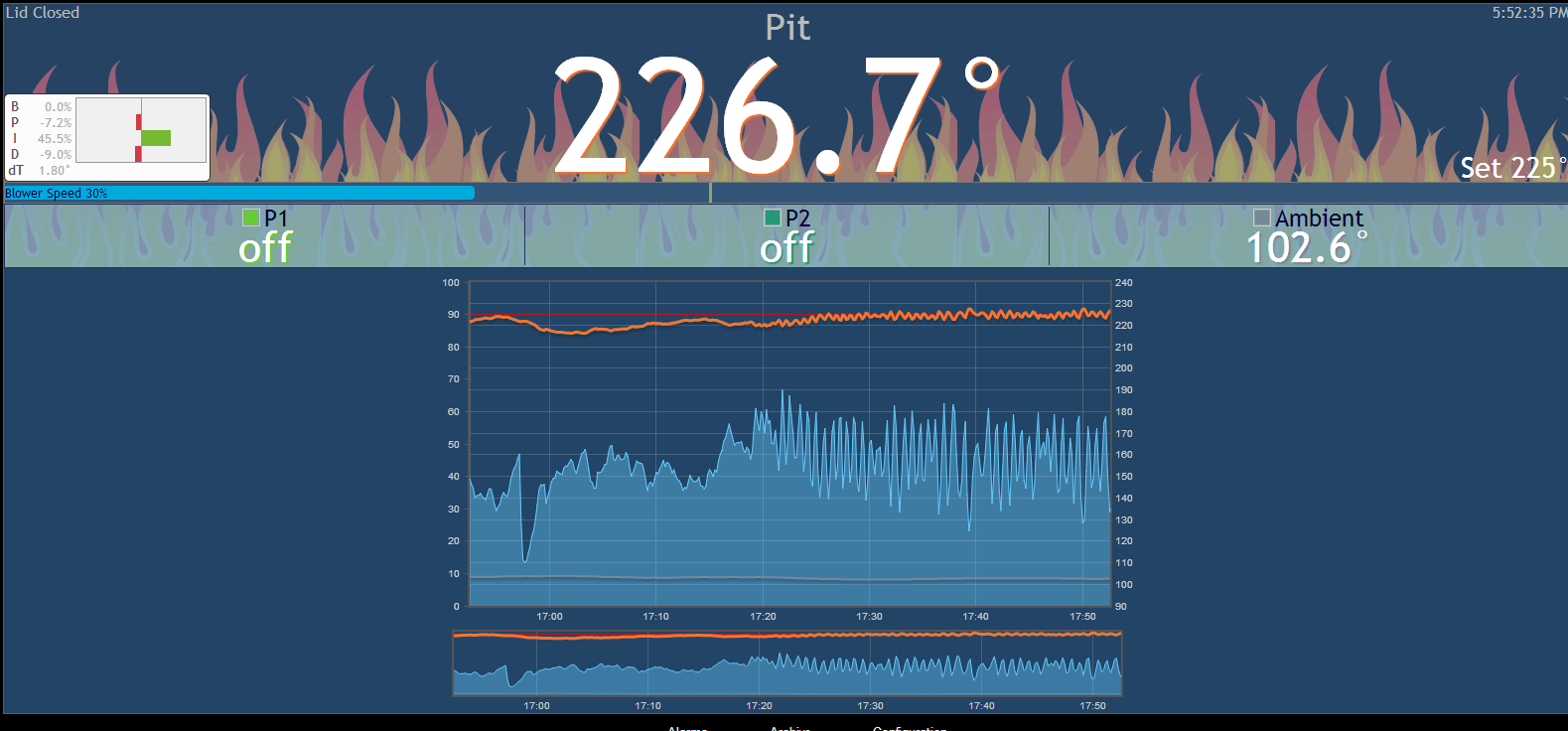

This is my first long smoke with the 4.2.4 Heatermeter and so far its going pretty good and I thought I would post my set up and PID settings.

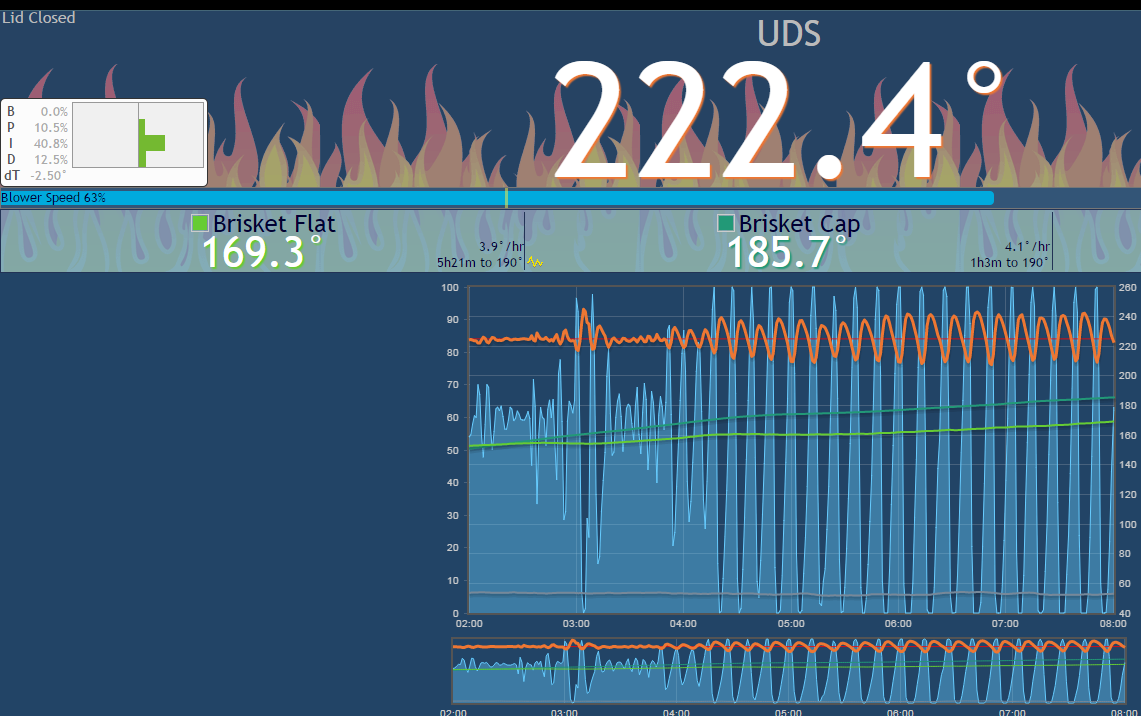

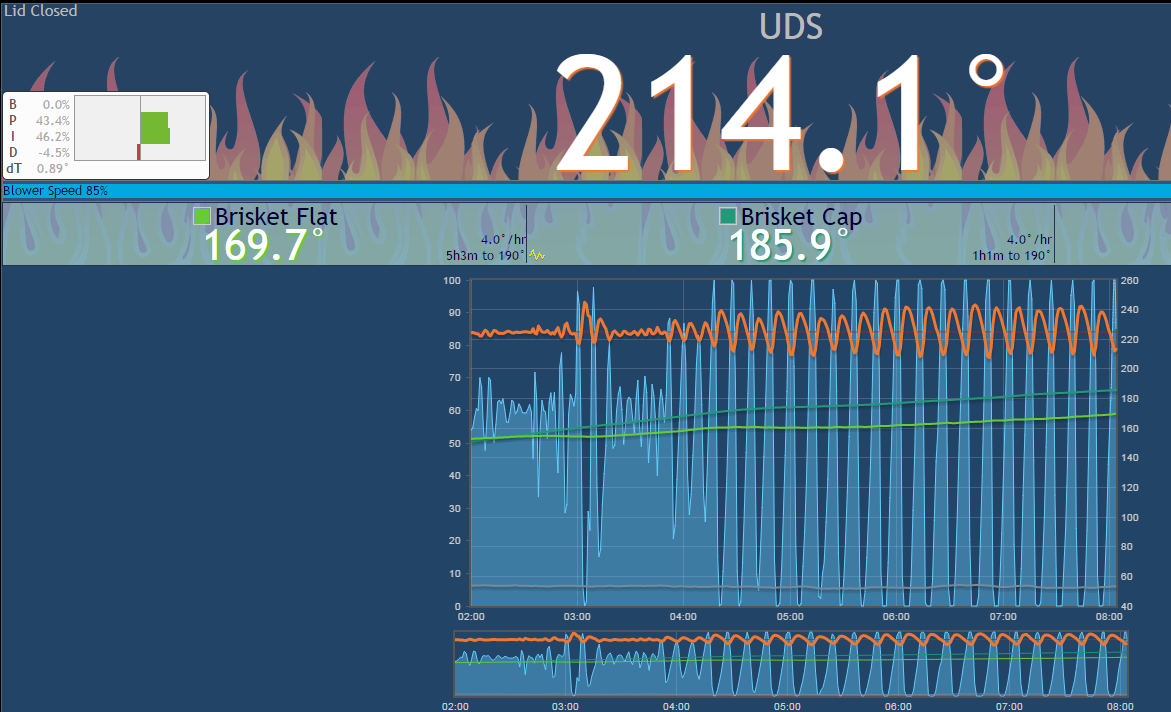

Im smoking on a UDS

3/4inch pipe inlet with a ball valve at half open(reason is that I have more control, with a smaller inlet but for higher temps its all open)

weber top with it fully open

Auber thermocouplehttp://www.auberins.com/index.php?main_page=product_info&cPath=20_3&products_id=327 a inch below center grate

Blower bfb1012HH-28cfm running at 30% max(anything higher and you get a cooling effect and overshoots when the heating of coals overcomes the cooling effect)probably could use a smaller blower, but this one has work for almost 5 years now(rain, snow, heat-very durable)

Rotodamper

http://uds.servebeer.com/luci

Im smoking on a UDS

3/4inch pipe inlet with a ball valve at half open(reason is that I have more control, with a smaller inlet but for higher temps its all open)

weber top with it fully open

Auber thermocouplehttp://www.auberins.com/index.php?main_page=product_info&cPath=20_3&products_id=327 a inch below center grate

Blower bfb1012HH-28cfm running at 30% max(anything higher and you get a cooling effect and overshoots when the heating of coals overcomes the cooling effect)probably could use a smaller blower, but this one has work for almost 5 years now(rain, snow, heat-very durable)

Rotodamper

http://uds.servebeer.com/luci

Last edited: